Aluminum frames offer superior durability and strength compared to plastic frames, making them ideal for long-lasting pet enclosures. They provide better resistance to weather conditions and are less prone to cracking or warping over time. Plastic frames, while lightweight and cost-effective, often lack the sturdiness and longevity required for active or large pets.

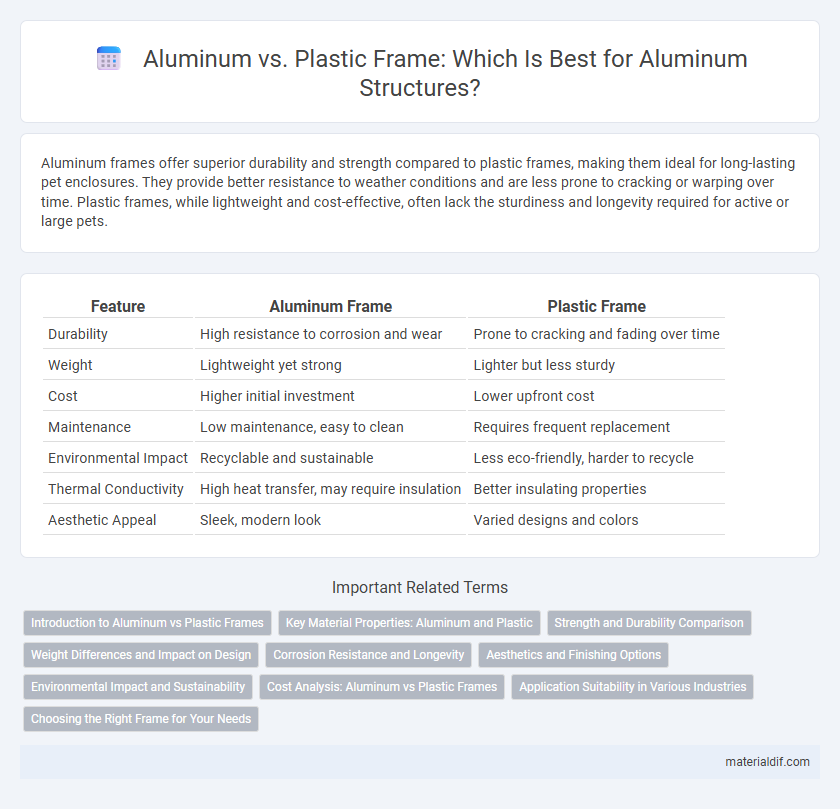

Table of Comparison

| Feature | Aluminum Frame | Plastic Frame |

|---|---|---|

| Durability | High resistance to corrosion and wear | Prone to cracking and fading over time |

| Weight | Lightweight yet strong | Lighter but less sturdy |

| Cost | Higher initial investment | Lower upfront cost |

| Maintenance | Low maintenance, easy to clean | Requires frequent replacement |

| Environmental Impact | Recyclable and sustainable | Less eco-friendly, harder to recycle |

| Thermal Conductivity | High heat transfer, may require insulation | Better insulating properties |

| Aesthetic Appeal | Sleek, modern look | Varied designs and colors |

Introduction to Aluminum vs Plastic Frames

Aluminum frames offer superior durability and lightweight strength compared to plastic frames, making them ideal for applications requiring long-lasting support and resistance to environmental factors. Plastic frames provide flexibility and cost-effectiveness but often lack the structural integrity and heat resistance found in aluminum. Choosing between aluminum and plastic frames depends on performance needs, weight considerations, and budget constraints.

Key Material Properties: Aluminum and Plastic

Aluminum frames exhibit superior strength-to-weight ratios, corrosion resistance, and thermal conductivity compared to plastic frames, making them ideal for structural applications requiring durability and heat dissipation. Plastic frames offer enhanced flexibility, lower density, and resistance to chemical degradation but generally lack the mechanical strength and heat resistance of aluminum. The choice between aluminum and plastic frames depends on the need for mechanical robustness, thermal stability, and environmental exposure.

Strength and Durability Comparison

Aluminum frames offer superior strength and durability compared to plastic frames, making them ideal for heavy-duty applications and long-term use. The metal's resistance to corrosion and ability to withstand impact without cracking contributes to a longer lifespan than plastic alternatives, which can degrade under UV exposure and mechanical stress. Aluminum's lightweight yet robust nature provides enhanced structural integrity, aligning well with demands for strength in industries like construction and automotive manufacturing.

Weight Differences and Impact on Design

Aluminum frames are significantly lighter than plastic frames, offering a weight advantage that enhances portability and ease of use in product design. The reduced weight of aluminum enables slimmer, more durable structures without compromising strength, allowing designers to create sleek, ergonomic products. In contrast, plastic frames, while often bulkier, provide flexibility in molding shapes but may add unwanted heft, impacting overall user comfort and product performance.

Corrosion Resistance and Longevity

Aluminum frames exhibit superior corrosion resistance compared to plastic frames due to their natural oxide layer, which protects against rust and environmental damage. This durability ensures that aluminum frames maintain structural integrity and appearance over long periods, making them ideal for outdoor and high-moisture applications. Plastic frames, while resistant to rust, often degrade faster under UV exposure and mechanical stress, resulting in shorter overall longevity.

Aesthetics and Finishing Options

Aluminum frames offer sleek, modern aesthetics with a smooth, metallic finish that enhances contemporary designs, while plastic frames provide versatility in color and texture but often lack the premium feel of metal. Aluminum allows for anodized, powder-coated, or brushed finishes, delivering a durable and sophisticated surface resistant to fading and corrosion. In contrast, plastic frames offer a broader range of vibrant hues and matte or glossy options, but they may show wear and discoloration over time more readily than aluminum.

Environmental Impact and Sustainability

Aluminum frames offer significant environmental advantages over plastic frames due to their recyclability and longer lifespan, reducing waste in landfills. The production of aluminum frames typically involves lower carbon emissions when recycled aluminum is used, whereas plastic frames contribute to microplastic pollution and have limited recyclability. Sustainable sourcing and closed-loop recycling systems for aluminum enhance environmental benefits, making aluminum frames a more eco-friendly choice.

Cost Analysis: Aluminum vs Plastic Frames

Aluminum frames typically have a higher upfront cost compared to plastic frames due to the material's durability and manufacturing complexity. Plastic frames, being cheaper to produce and lightweight, offer cost savings but often lack the long-term resilience of aluminum. When considering lifecycle costs, aluminum frames provide better value through greater longevity and reduced maintenance expenses.

Application Suitability in Various Industries

Aluminum frames offer superior durability, corrosion resistance, and lightweight strength, making them ideal for automotive, aerospace, and construction industries where structural integrity and longevity are critical. Plastic frames, known for their cost-effectiveness and corrosion-free properties, are favored in consumer electronics, medical devices, and packaging industries where flexibility and lightweight features are essential. Selecting the appropriate frame material depends on the specific industry requirements for strength, weight, cost, and environmental exposure.

Choosing the Right Frame for Your Needs

Aluminum frames offer superior durability, lightweight strength, and corrosion resistance, making them ideal for long-lasting performance in various applications. Plastic frames provide cost-effective, flexible options with better impact resistance but generally lack the structural rigidity of aluminum. Selecting the right frame depends on prioritizing factors such as strength requirements, budget constraints, and the intended environment for use.

Aluminum Frame vs Plastic Frame Infographic

materialdif.com

materialdif.com