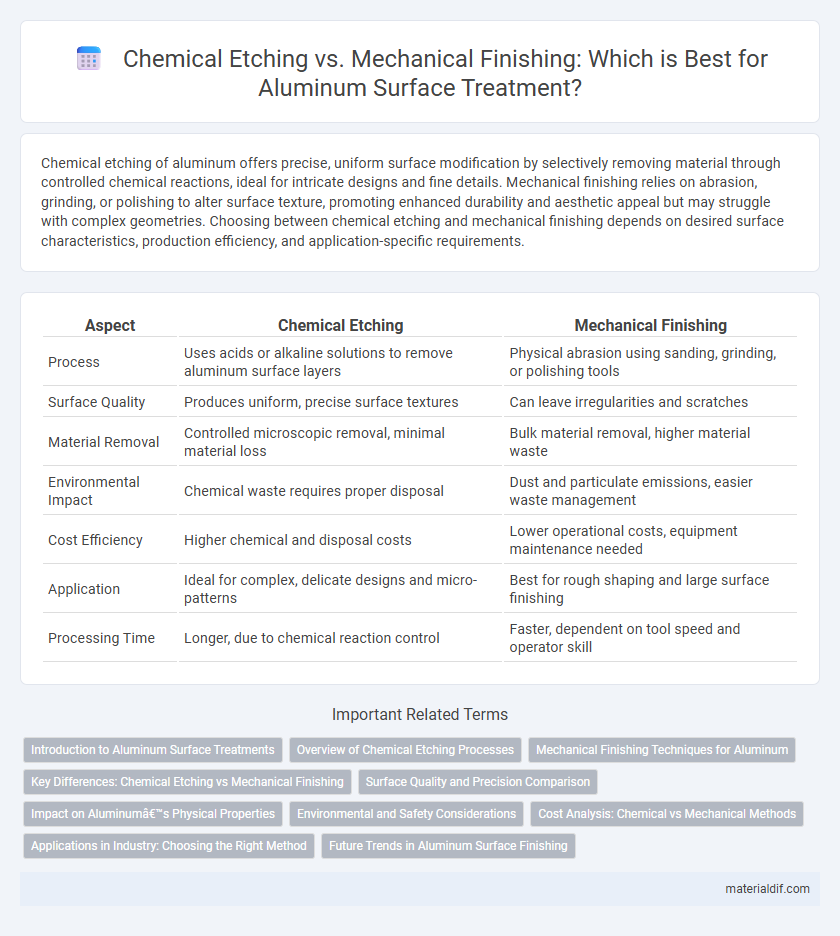

Chemical etching of aluminum offers precise, uniform surface modification by selectively removing material through controlled chemical reactions, ideal for intricate designs and fine details. Mechanical finishing relies on abrasion, grinding, or polishing to alter surface texture, promoting enhanced durability and aesthetic appeal but may struggle with complex geometries. Choosing between chemical etching and mechanical finishing depends on desired surface characteristics, production efficiency, and application-specific requirements.

Table of Comparison

| Aspect | Chemical Etching | Mechanical Finishing |

|---|---|---|

| Process | Uses acids or alkaline solutions to remove aluminum surface layers | Physical abrasion using sanding, grinding, or polishing tools |

| Surface Quality | Produces uniform, precise surface textures | Can leave irregularities and scratches |

| Material Removal | Controlled microscopic removal, minimal material loss | Bulk material removal, higher material waste |

| Environmental Impact | Chemical waste requires proper disposal | Dust and particulate emissions, easier waste management |

| Cost Efficiency | Higher chemical and disposal costs | Lower operational costs, equipment maintenance needed |

| Application | Ideal for complex, delicate designs and micro-patterns | Best for rough shaping and large surface finishing |

| Processing Time | Longer, due to chemical reaction control | Faster, dependent on tool speed and operator skill |

Introduction to Aluminum Surface Treatments

Aluminum surface treatments such as chemical etching and mechanical finishing enhance corrosion resistance and surface texture for improved functionality. Chemical etching uses acid-based solutions to precisely remove oxide layers, creating uniform micro-patterns ideal for electronics and aerospace applications. Mechanical finishing, including sanding and polishing, physically smooths the aluminum surface to increase reflectivity and prepare it for subsequent coating or anodizing processes.

Overview of Chemical Etching Processes

Chemical etching of aluminum involves using acid-based or alkaline solutions to selectively remove material and create precise patterns or surface textures with minimal mechanical stress. This process enables high-resolution detailing, excellent repeatability, and is ideal for complex geometries that are difficult to achieve through mechanical finishing methods. Controlled exposure time, solution concentration, and temperature are critical parameters to ensure consistent etch depth and surface quality during chemical etching.

Mechanical Finishing Techniques for Aluminum

Mechanical finishing techniques for aluminum include processes such as grinding, polishing, and abrasive blasting, which enhance surface smoothness and improve aesthetic appeal. These methods effectively remove surface imperfections and prepare aluminum for subsequent coating or anodizing, ensuring better adhesion and corrosion resistance. Common mechanical finishes like buffing and vibratory finishing offer consistent texture control and are widely used in aerospace, automotive, and architectural applications.

Key Differences: Chemical Etching vs Mechanical Finishing

Chemical etching of aluminum involves using acid or alkaline solutions to selectively remove material, enabling intricate and precise patterns with minimal mechanical stress, while mechanical finishing relies on abrasive or physical methods like grinding and polishing to smooth surfaces and improve appearance. Chemical etching provides high dimensional accuracy and uniformity for complex designs, whereas mechanical finishing is better suited for removing surface defects and creating specific textures. The choice depends on factors such as part complexity, tolerance requirements, surface finish quality, and production volume.

Surface Quality and Precision Comparison

Chemical etching of aluminum achieves superior surface quality by producing smooth, uniform finishes without mechanical stress or tool marks, enhancing precision for intricate patterns and micro-features. Mechanical finishing methods, such as grinding or sanding, can introduce surface irregularities, scratches, or deformation, reducing dimensional accuracy and limiting fine-detail replication. Precise control over etching parameters in chemical processes ensures consistent results suitable for high-tolerance applications where sharp edges and delicate textures are critical.

Impact on Aluminum’s Physical Properties

Chemical etching selectively removes surface layers of aluminum, enhancing surface texture without significantly altering its mechanical strength or dimensional stability. Mechanical finishing techniques such as grinding and polishing physically abrade the aluminum surface, which can lead to microstructural changes and potential residual stresses affecting its hardness and fatigue resistance. These differences influence aluminum's corrosion resistance and suitability for precision applications, where chemical etching offers more controlled surface modification compared to the aggressive nature of mechanical finishing.

Environmental and Safety Considerations

Chemical etching of aluminum involves hazardous acids and produces toxic waste that requires specialized disposal, posing significant environmental and safety risks. Mechanical finishing uses abrasives and machinery, generating less harmful waste and reducing chemical exposure but can cause dust and noise hazards requiring protective measures. Selecting appropriate finishing methods depends on balancing ecological impact and worker safety protocols.

Cost Analysis: Chemical vs Mechanical Methods

Chemical etching of aluminum offers lower tooling costs and greater precision, making it ideal for complex designs with minimal material waste. Mechanical finishing typically incurs higher labor expenses and equipment maintenance costs, especially for large-scale or intricate projects. Overall, chemical methods provide a cost-effective solution when balancing initial investment against long-term production efficiency.

Applications in Industry: Choosing the Right Method

Chemical etching offers precise and intricate designs ideal for aerospace components and electronics where tight tolerances are required. Mechanical finishing excels in heavy-duty applications such as automotive parts and architectural elements, providing durability and surface smoothness. Selecting the right method depends on factors like surface complexity, production volume, and the specific performance requirements of aluminum products.

Future Trends in Aluminum Surface Finishing

Advancements in aluminum surface finishing emphasize sustainable and precision-focused methods, with chemical etching evolving towards eco-friendly solutions using biodegradable reagents to reduce environmental impact. Mechanical finishing integrates automated robotic systems and nanotechnology coatings, enhancing surface durability and corrosion resistance at a microstructural level. Emerging trends prioritize hybrid techniques combining chemical and mechanical processes to optimize efficiency and achieve superior aesthetic and functional properties in aluminum applications.

Chemical Etching vs Mechanical Finishing Infographic

materialdif.com

materialdif.com