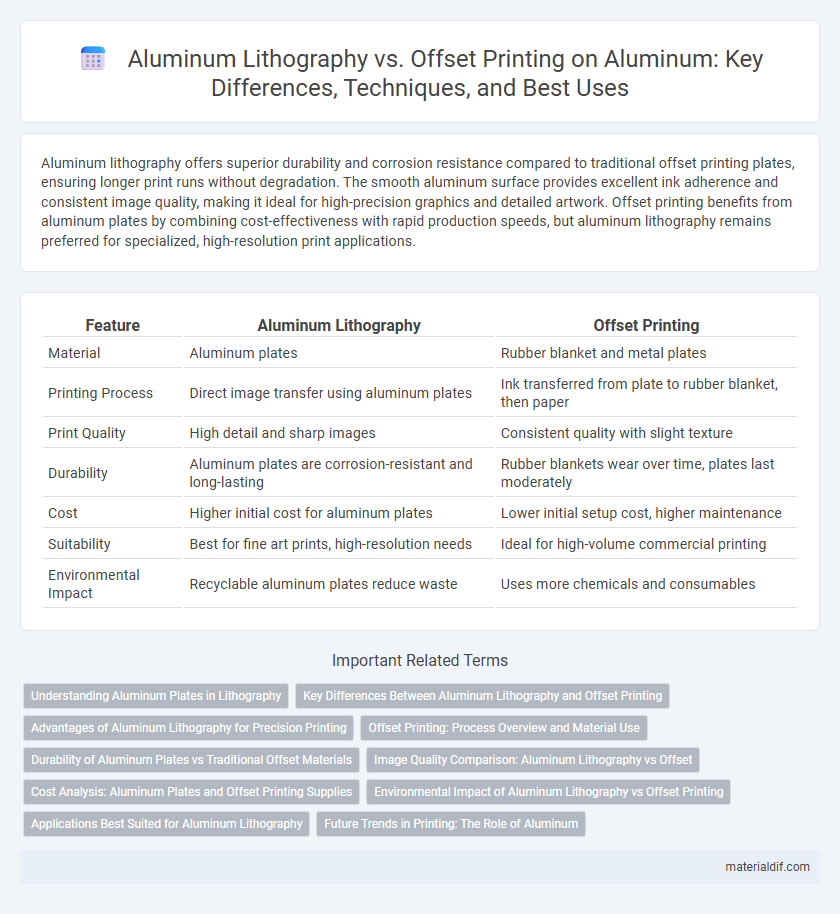

Aluminum lithography offers superior durability and corrosion resistance compared to traditional offset printing plates, ensuring longer print runs without degradation. The smooth aluminum surface provides excellent ink adherence and consistent image quality, making it ideal for high-precision graphics and detailed artwork. Offset printing benefits from aluminum plates by combining cost-effectiveness with rapid production speeds, but aluminum lithography remains preferred for specialized, high-resolution print applications.

Table of Comparison

| Feature | Aluminum Lithography | Offset Printing |

|---|---|---|

| Material | Aluminum plates | Rubber blanket and metal plates |

| Printing Process | Direct image transfer using aluminum plates | Ink transferred from plate to rubber blanket, then paper |

| Print Quality | High detail and sharp images | Consistent quality with slight texture |

| Durability | Aluminum plates are corrosion-resistant and long-lasting | Rubber blankets wear over time, plates last moderately |

| Cost | Higher initial cost for aluminum plates | Lower initial setup cost, higher maintenance |

| Suitability | Best for fine art prints, high-resolution needs | Ideal for high-volume commercial printing |

| Environmental Impact | Recyclable aluminum plates reduce waste | Uses more chemicals and consumables |

Understanding Aluminum Plates in Lithography

Aluminum plates play a crucial role in lithography by providing a stable, durable surface that ensures high-quality image transfer. Their corrosion resistance and smooth texture make them ideal for repeated use in printing presses, enhancing both print clarity and longevity. Compared to offset printing, which uses rubber blankets, aluminum plates directly hold the image, making them essential for precise, detailed lithographic reproduction.

Key Differences Between Aluminum Lithography and Offset Printing

Aluminum lithography uses aluminum plates coated with photosensitive material to create printing images, providing superior durability and resistance to corrosion compared to traditional materials used in offset printing. Offset printing transfers ink from a plate to a rubber blanket before applying it to the printing surface, offering higher flexibility for various paper types and faster production speeds. The key differences include the material of the printing plates, image transfer mechanism, and suitability for high-volume production with precise image quality.

Advantages of Aluminum Lithography for Precision Printing

Aluminum lithography offers superior precision printing due to its stable and durable metal plate, which maintains fine detail and sharp image quality throughout long print runs. The rigidity of aluminum plates minimizes distortion and ensures consistent registration, making it ideal for high-resolution graphic and fine art reproductions. Compared to offset printing on flexible plates, aluminum lithography delivers enhanced accuracy and longevity in producing intricate designs.

Offset Printing: Process Overview and Material Use

Offset printing utilizes a plate made from aluminum, which is coated with light-sensitive chemicals to form the image area. The process involves transferring an inked image from the aluminum plate to a rubber blanket before pressing it onto paper or other substrates, enhancing print quality and efficiency. This method supports high-volume production with consistent color accuracy, making it ideal for newspapers, brochures, and packaging materials.

Durability of Aluminum Plates vs Traditional Offset Materials

Aluminum plates used in lithography offer superior durability compared to traditional offset printing materials, enabling longer print runs without degradation. Their resistance to wear and corrosion ensures consistent image quality and reduces the need for frequent plate replacements. This durability translates into cost-effectiveness and higher efficiency for commercial printing processes.

Image Quality Comparison: Aluminum Lithography vs Offset

Aluminum lithography produces sharper, more vibrant images due to its superior ink absorption and smooth metal surface, resulting in enhanced detail and color consistency compared to offset printing. Offset printing often shows slight image distortion and less color accuracy because of its indirect printing process on rubber blankets and paper sheets. The durability of aluminum plates also contributes to maintaining high image quality over longer print runs, making it ideal for fine art and high-resolution commercial prints.

Cost Analysis: Aluminum Plates and Offset Printing Supplies

Aluminum lithography typically incurs higher upfront costs due to the price of aluminum plates, which range from $5 to $15 per sheet depending on size and coating quality. Offset printing supplies, such as rubber blankets, inks, and rollers, add recurring expenses averaging $200 to $500 per press run, influencing overall operational budgets. While aluminum plates offer durability and precision for long print runs, offset printing supplies require frequent replacement, impacting cost efficiency in short to medium print volumes.

Environmental Impact of Aluminum Lithography vs Offset Printing

Aluminum lithography generates less chemical waste compared to offset printing, which traditionally relies on water and oil-based inks that contribute to higher solvent emissions. The reusable aluminum plates in lithography reduce material waste and energy consumption during production, resulting in a smaller carbon footprint than the disposable plates often used in offset printing. Aluminum lithography's efficient plate recycling process minimizes landfill waste, making it a more environmentally sustainable choice for high-volume print jobs.

Applications Best Suited for Aluminum Lithography

Aluminum lithography excels in high-quality image reproduction and fine detail, making it ideal for packaging, luxury labels, and art prints where precision and durability are critical. Its superior resistance to corrosion and wear suits applications requiring long production runs and consistent image fidelity. Industries like cosmetics, food and beverage, and pharmaceuticals frequently choose aluminum lithography for its ability to deliver sharp, vibrant colors and clear branding.

Future Trends in Printing: The Role of Aluminum

Aluminum lithography is poised to revolutionize printing with its superior durability, recyclability, and precision compared to traditional offset printing plates. Innovations in anodized aluminum substrates enhance image quality and plate longevity, reducing waste and operational costs in commercial printing applications. The increasing demand for sustainable materials and high-resolution outputs positions aluminum as a key driver in the future of eco-friendly, high-performance printing technologies.

Aluminum Lithography vs Offset Printing Infographic

materialdif.com

materialdif.com