Direct Chill Casting and Continuous Casting are two primary methods used in aluminum production, each offering distinct advantages. Direct Chill Casting involves pouring molten aluminum into a water-cooled mold, producing large billets with excellent mechanical properties and minimal porosity. Continuous Casting, on the other hand, allows for a continuous flow of molten aluminum through a cooled mold, enhancing efficiency and reducing material waste while maintaining consistent quality.

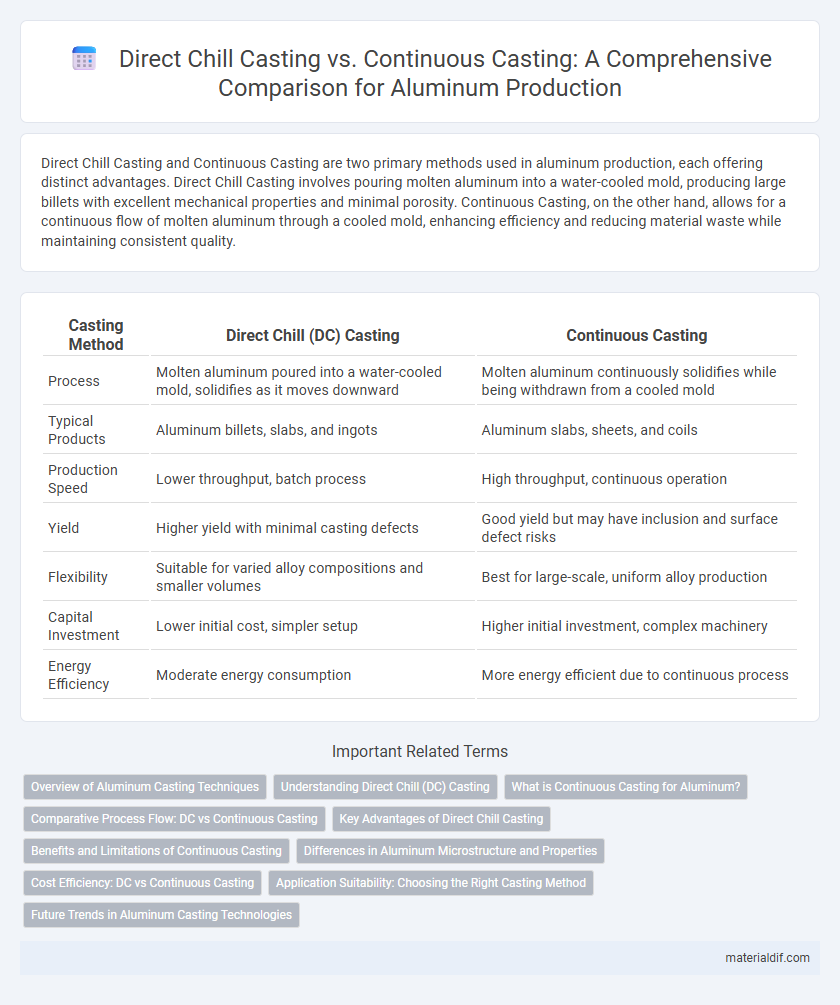

Table of Comparison

| Casting Method | Direct Chill (DC) Casting | Continuous Casting |

|---|---|---|

| Process | Molten aluminum poured into a water-cooled mold, solidifies as it moves downward | Molten aluminum continuously solidifies while being withdrawn from a cooled mold |

| Typical Products | Aluminum billets, slabs, and ingots | Aluminum slabs, sheets, and coils |

| Production Speed | Lower throughput, batch process | High throughput, continuous operation |

| Yield | Higher yield with minimal casting defects | Good yield but may have inclusion and surface defect risks |

| Flexibility | Suitable for varied alloy compositions and smaller volumes | Best for large-scale, uniform alloy production |

| Capital Investment | Lower initial cost, simpler setup | Higher initial investment, complex machinery |

| Energy Efficiency | Moderate energy consumption | More energy efficient due to continuous process |

Overview of Aluminum Casting Techniques

Direct Chill casting involves pouring molten aluminum into a water-cooled mold, promoting rapid solidification and producing high-quality billets with minimal segregation and superior mechanical properties. Continuous casting continuously extracts solidified aluminum from an open-ended mold, enabling high-volume production with consistent cross-sectional shapes, ideal for large-scale manufacturing. Both methods optimize aluminum microstructure but differ in operational efficiency and surface finish, influencing their application in aerospace, automotive, and construction industries.

Understanding Direct Chill (DC) Casting

Direct Chill (DC) casting is a primary aluminum casting method where molten aluminum is poured into a water-cooled mold, allowing rapid solidification and continuous ingot production. This process improves the microstructure by reducing segregation and porosity, resulting in higher-quality billets or slabs ideal for rolling and extrusion. Compared to continuous casting, DC casting offers superior control over solidification rates and grain structure, enhancing mechanical properties and surface finish.

What is Continuous Casting for Aluminum?

Continuous casting for aluminum is a highly efficient industrial process where molten aluminum is solidified into a semi-finished billet, bloom, or slab continuously, enabling large-scale production with consistent quality. This method reduces waste and energy consumption compared to direct chill casting by maintaining a steady flow of molten metal through a water-cooled mold, resulting in uniform microstructure and improved mechanical properties. Continuous casting is essential in aluminum manufacturing for producing raw shapes ready for downstream rolling, extrusion, and fabrication processes.

Comparative Process Flow: DC vs Continuous Casting

Direct Chill (DC) casting involves pouring molten aluminum into a water-cooled mold where the solidified shell is continuously withdrawn and cooled by water sprays, promoting rapid solidification and reduced porosity. Continuous casting feeds molten aluminum through a cooled mold, producing a continuous strand that is cut into billets or slabs, offering higher production rates and consistent mechanical properties. While DC casting excels in producing large ingots with homogenous structures, continuous casting provides superior dimensional control and efficiency for high-volume manufacturing.

Key Advantages of Direct Chill Casting

Direct Chill Casting offers superior control over microstructure and reduced internal defects in aluminum billets compared to Continuous Casting. This process enables rapid solidification and effective heat extraction, resulting in enhanced mechanical properties and improved surface quality of aluminum products. Additionally, Direct Chill Casting supports larger cross-sectional sizes, making it ideal for producing high-quality aluminum billets used in critical applications.

Benefits and Limitations of Continuous Casting

Continuous casting of aluminum offers benefits such as higher production rates, improved material yield, and better control over microstructure, enhancing mechanical properties and surface quality. However, limitations include the high initial investment cost, complexity in equipment maintenance, and restrictions on casting alloy variety compared to direct chill casting. Continuous casting is optimal for large-scale operations requiring consistent quality but may lack flexibility for smaller batches or specialized alloys.

Differences in Aluminum Microstructure and Properties

Direct Chill (DC) casting produces aluminum billets with a coarse dendritic microstructure, resulting in lower mechanical strength but improved machinability and reduced residual stresses. Continuous casting generates a finer grain structure, enhancing tensile strength and ductility due to faster solidification rates and better control of cooling. The microstructural differences influence properties like corrosion resistance and formability, with DC casting favored for large cross-sections and continuous casting preferred for high-volume production of thinner sections.

Cost Efficiency: DC vs Continuous Casting

Direct Chill (DC) casting typically involves lower initial equipment investment compared to continuous casting, making it more cost-effective for small to medium-scale aluminum production. Continuous casting offers higher yield and reduced scrap rates, which can lead to greater long-term cost savings in large-scale operations. The choice between DC and continuous casting depends on production volume, with continuous casting generally providing superior cost efficiency in high-capacity aluminum manufacturing.

Application Suitability: Choosing the Right Casting Method

Direct Chill casting is highly suitable for producing large aluminum billets and slabs used in aerospace and automotive industries due to its ability to minimize internal defects and ensure uniform grain structure. Continuous casting excels in high-volume production of thin aluminum strips and sheets ideal for packaging and construction applications because of its consistent thickness and surface quality. Selecting between these methods depends on the required product dimensions, mechanical properties, and production scale.

Future Trends in Aluminum Casting Technologies

Future trends in aluminum casting technologies emphasize advancements in Direct Chill (DC) casting and Continuous Casting processes to enhance efficiency, reduce defects, and improve mechanical properties. Innovations include integrating real-time process monitoring with AI-driven predictive maintenance and the adoption of electromagnetic stirring to achieve finer grain structures and better alloy homogeneity. These developments aim to meet growing industry demands for lightweight, high-strength aluminum components, particularly in automotive and aerospace sectors.

Direct Chill Casting vs Continuous Casting Infographic

materialdif.com

materialdif.com