Alclad aluminum features a thin layer of pure aluminum bonded to an aluminum alloy core, providing enhanced corrosion resistance compared to uncoated aluminum. This layered composition combines the strength of the alloy with the protective qualities of the pure aluminum surface, making it ideal for applications exposed to harsh environments. Uncoated aluminum, while lighter and often more cost-effective, lacks this corrosion protection and may deteriorate faster when exposed to moisture and chemicals.

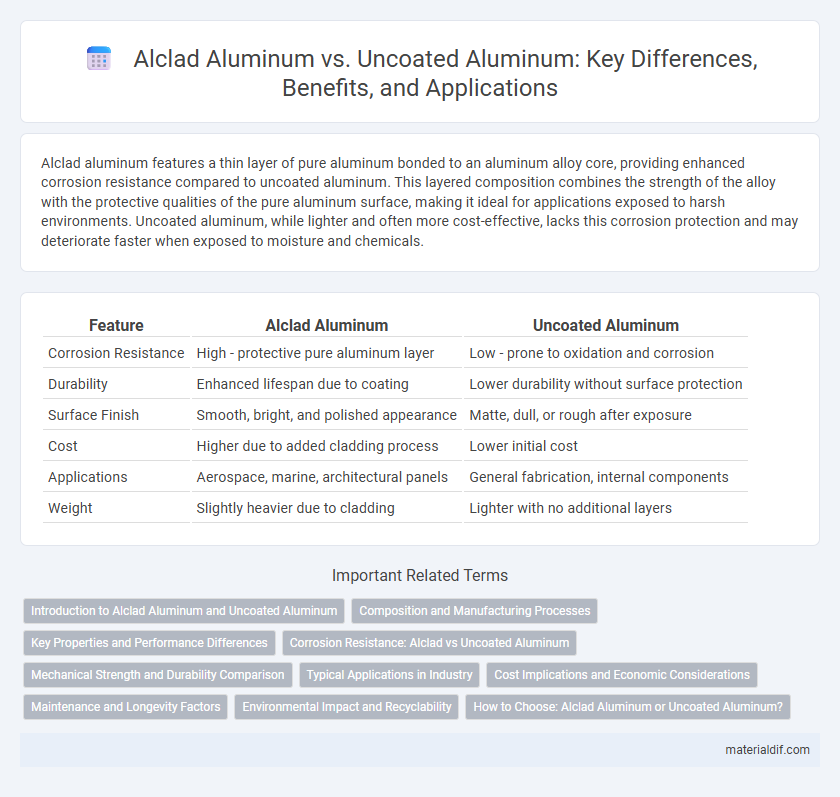

Table of Comparison

| Feature | Alclad Aluminum | Uncoated Aluminum |

|---|---|---|

| Corrosion Resistance | High - protective pure aluminum layer | Low - prone to oxidation and corrosion |

| Durability | Enhanced lifespan due to coating | Lower durability without surface protection |

| Surface Finish | Smooth, bright, and polished appearance | Matte, dull, or rough after exposure |

| Cost | Higher due to added cladding process | Lower initial cost |

| Applications | Aerospace, marine, architectural panels | General fabrication, internal components |

| Weight | Slightly heavier due to cladding | Lighter with no additional layers |

Introduction to Alclad Aluminum and Uncoated Aluminum

Alclad aluminum consists of a high-purity aluminum core bonded to a thin layer of corrosion-resistant alloy, enhancing its durability and resistance to environmental factors compared to uncoated aluminum. Uncoated aluminum, while lightweight and malleable, is more susceptible to oxidation and corrosion when exposed to moisture and air. The Alclad process provides significant advantages in aerospace and marine applications, where material longevity and strength are critical.

Composition and Manufacturing Processes

Alclad aluminum features a core of high-strength aluminum alloy bonded with thin layers of pure aluminum, providing enhanced corrosion resistance compared to uncoated aluminum. The manufacturing process of Alclad involves metallurgical bonding through rolling, which creates a durable composite material with improved surface protection. In contrast, uncoated aluminum consists solely of a single alloy layer without additional protective cladding, making it more susceptible to oxidation and environmental degradation.

Key Properties and Performance Differences

Alclad aluminum features a corrosion-resistant pure aluminum outer layer bonded to a high-strength aluminum alloy core, significantly enhancing durability compared to uncoated aluminum. Key properties include superior resistance to oxidation, improved surface finish, and increased lifespan in marine and aerospace applications. Performance differences highlight Alclad's ability to maintain structural integrity and aesthetic appeal in harsh environments, whereas uncoated aluminum is more prone to corrosion and surface degradation.

Corrosion Resistance: Alclad vs Uncoated Aluminum

Alclad aluminum features a thin, pure aluminum coating bonded to a high-strength aluminum alloy core, significantly enhancing corrosion resistance by protecting the core from environmental exposure. Uncoated aluminum lacks this protective layer, making it more susceptible to oxidation, pitting, and corrosion, especially in harsh or marine environments. The aluminized surface of Alclad forms a stable oxide layer that acts as a barrier against moisture and chemicals, extending the material's lifespan compared to uncoated aluminum.

Mechanical Strength and Durability Comparison

Alclad aluminum features a core of high-strength aluminum alloy coated with a thin layer of pure aluminum, enhancing corrosion resistance without compromising mechanical strength. Uncoated aluminum, while lightweight, is more susceptible to corrosion and surface degradation, potentially reducing its long-term durability in harsh environments. The protective cladding on Alclad aluminum significantly extends the service life of components by maintaining structural integrity under stress and exposure.

Typical Applications in Industry

Alclad aluminum is widely used in aerospace and marine industries due to its corrosion-resistant properties, making it ideal for aircraft skins and shipbuilding. Uncoated aluminum is favored in automotive and construction sectors where lightweight and malleability are critical but exposure to harsh environments is limited. Typical applications leverage Alclad aluminum for enhanced durability in external components, while uncoated aluminum suits internal structures and non-corrosive settings.

Cost Implications and Economic Considerations

Alclad aluminum, featuring a corrosion-resistant pure aluminum surface bonded to a high-strength aluminum alloy core, generally incurs higher material costs compared to uncoated aluminum due to its manufacturing complexity and enhanced durability. The longer lifespan and reduced maintenance requirements of Alclad aluminum can result in lower total cost of ownership over time, making it economically advantageous for aerospace and marine applications. In contrast, uncoated aluminum offers initial cost savings but often requires frequent replacement or protective treatments, leading to higher lifecycle expenses.

Maintenance and Longevity Factors

Alclad aluminum features a pure aluminum coating that significantly enhances corrosion resistance, reducing maintenance requirements compared to uncoated aluminum. The protective layer minimizes oxidation and surface degradation, extending the material's lifespan in harsh environments. Uncoated aluminum, lacking this barrier, demands more frequent cleaning and protective treatments to prevent corrosion and preserve its structural integrity.

Environmental Impact and Recyclability

Alclad aluminum features a pure aluminum coating that enhances corrosion resistance, reducing the need for chemical treatments and extending product lifespan, which lessens environmental impact compared to uncoated aluminum. Both Alclad and uncoated aluminum are highly recyclable, with recycling rates exceeding 90%, but the Alclad's multi-layer composition requires specialized recycling processes to separate the layers efficiently. The enhanced durability of Alclad aluminum decreases replacement frequency, indirectly conserving resources and lowering the overall carbon footprint in applications such as aerospace and transportation.

How to Choose: Alclad Aluminum or Uncoated Aluminum?

Choosing between Alclad aluminum and uncoated aluminum depends on the intended application and environmental exposure. Alclad aluminum features a corrosion-resistant pure aluminum surface, making it ideal for aerospace and marine use where durability and oxidation resistance are critical. Uncoated aluminum is lighter and more cost-effective but requires protective treatments or coatings for outdoor or corrosive environments.

Alclad aluminum vs uncoated aluminum Infographic

materialdif.com

materialdif.com