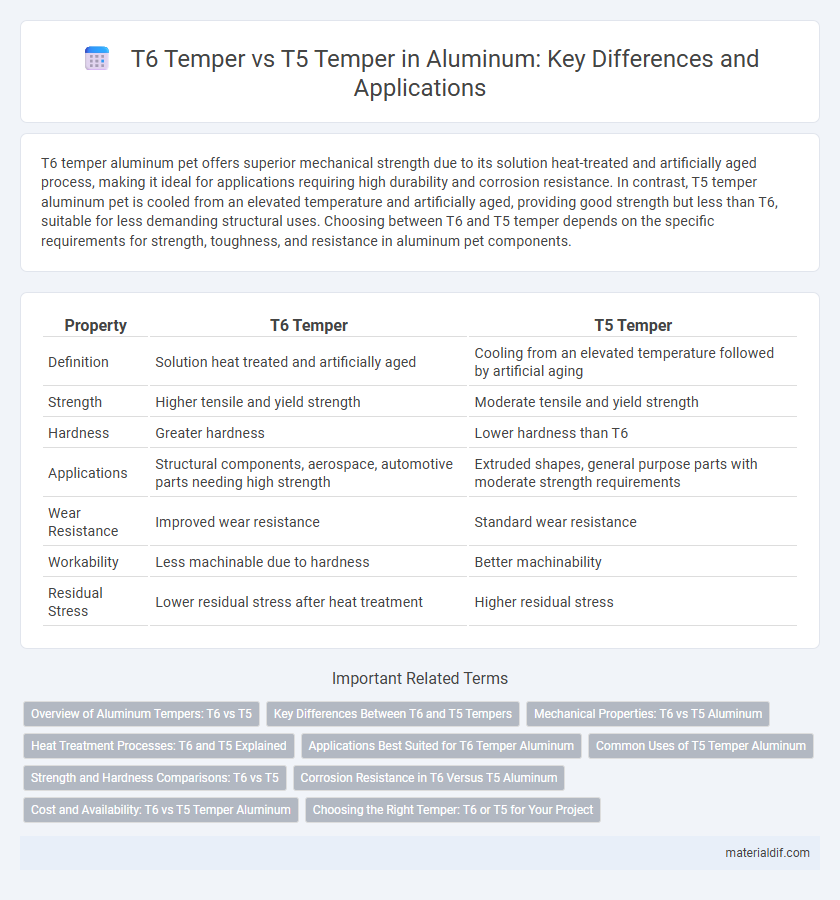

T6 temper aluminum pet offers superior mechanical strength due to its solution heat-treated and artificially aged process, making it ideal for applications requiring high durability and corrosion resistance. In contrast, T5 temper aluminum pet is cooled from an elevated temperature and artificially aged, providing good strength but less than T6, suitable for less demanding structural uses. Choosing between T6 and T5 temper depends on the specific requirements for strength, toughness, and resistance in aluminum pet components.

Table of Comparison

| Property | T6 Temper | T5 Temper |

|---|---|---|

| Definition | Solution heat treated and artificially aged | Cooling from an elevated temperature followed by artificial aging |

| Strength | Higher tensile and yield strength | Moderate tensile and yield strength |

| Hardness | Greater hardness | Lower hardness than T6 |

| Applications | Structural components, aerospace, automotive parts needing high strength | Extruded shapes, general purpose parts with moderate strength requirements |

| Wear Resistance | Improved wear resistance | Standard wear resistance |

| Workability | Less machinable due to hardness | Better machinability |

| Residual Stress | Lower residual stress after heat treatment | Higher residual stress |

Overview of Aluminum Tempers: T6 vs T5

Aluminum T6 temper undergoes solution heat treatment followed by artificial aging, resulting in higher strength and improved corrosion resistance compared to T5 temper, which is cooled from an elevated temperature and artificially aged without solution treatment. T6 temper is widely used in structural applications requiring maximum mechanical performance, while T5 temper suits components where moderate strength with easier machinability is acceptable. Understanding the distinction between T6 and T5 tempers is crucial for optimizing aluminum alloy selection based on specific engineering requirements.

Key Differences Between T6 and T5 Tempers

T6 temper aluminum undergoes solution heat treatment and artificial aging, resulting in higher strength and improved mechanical properties compared to T5 temper, which is artificially aged without prior solution heat treatment. T6 alloys exhibit enhanced tensile strength and hardness, making them ideal for structural applications requiring high durability. In contrast, T5 temper is often used when moderate strength and improved machinability are sufficient, offering a cost-effective option with faster processing times.

Mechanical Properties: T6 vs T5 Aluminum

T6 aluminum alloy undergoes solution heat treatment followed by artificial aging, resulting in higher tensile strength and hardness compared to T5 temper, which is cooled from an elevated temperature and artificially aged without solution treatment. The T6 temper typically exhibits yield strength values around 240 MPa to 350 MPa, whereas T5 aluminum shows lower strength levels, usually between 150 MPa and 250 MPa. Fatigue resistance and hardness in T6 temper significantly outperform T5, making T6 ideal for structural applications requiring enhanced mechanical performance.

Heat Treatment Processes: T6 and T5 Explained

T6 temper aluminum undergoes solution heat treatment followed by artificial aging, resulting in higher strength and improved mechanical properties. T5 temper aluminum is cooled from an elevated temperature shaping process and then artificially aged without a prior solution heat treatment. The key difference lies in T6's solution heat treatment step, which enhances hardness and tensile strength compared to the T5 temper.

Applications Best Suited for T6 Temper Aluminum

T6 temper aluminum, characterized by its solution heat-treated and artificially aged properties, offers superior strength and hardness compared to T5 temper, which is only artificially aged after cooling from a hot working process. This enhanced mechanical performance makes T6 aluminum ideal for aerospace components, automotive parts, and structural applications requiring high load-bearing capacity and resistance to stress. Industries demanding durability and longevity frequently prefer T6 temper for critical parts such as aircraft frames, automotive chassis, and high-performance machinery.

Common Uses of T5 Temper Aluminum

T5 temper aluminum is commonly used in applications requiring moderate strength combined with good corrosion resistance, such as in structural components, automotive parts, and aerospace fittings. It is favored for extruded aluminum products like frames, panels, and tubing where enhanced mechanical properties after artificial aging are beneficial. Unlike T6 temper, which undergoes full solution heat treatment, T5 temper involves cooling from an elevated temperature shape and artificial aging, making it suitable for processes demanding less intensive heat treatment.

Strength and Hardness Comparisons: T6 vs T5

Aluminum alloys in T6 temper exhibit higher strength and hardness compared to T5 temper due to the artificial aging process that enhances their mechanical properties. T6 temper undergoes solution heat treatment followed by artificial aging, resulting in improved tensile strength and yield strength, making it ideal for structural applications. In contrast, T5 temper, which involves cooling from an elevated temperature followed by artificial aging, generally offers lower strength and hardness, suitable for less demanding mechanical uses.

Corrosion Resistance in T6 Versus T5 Aluminum

T6 temper aluminum exhibits improved corrosion resistance compared to T5 temper due to its solution heat-treated and artificially aged microstructure, which enhances the alloy's homogeneity and reduces susceptibility to intergranular attack. The T5 temper, involving only artificial aging without prior solution heat treatment, tends to have residual stresses and microstructural heterogeneities that can increase the risk of localized corrosion. Consequently, T6 temper aluminum is preferred in applications exposed to harsh environmental conditions where long-term corrosion resistance is critical.

Cost and Availability: T6 vs T5 Temper Aluminum

T6 temper aluminum typically costs more than T5 due to its additional solution heat treatment and artificial aging processes, which enhance strength and durability. T5 temper aluminum is generally more available and cost-effective for applications requiring moderate strength, as it involves only cooling from an elevated temperature. Suppliers often stock T5 aluminum in larger quantities, making it more accessible and economical for mass production and general engineering uses.

Choosing the Right Temper: T6 or T5 for Your Project

Choosing between T6 and T5 tempers for aluminum depends primarily on the desired strength and finish requirements of the project. T6 temper involves solution heat treatment and artificial aging, resulting in higher tensile strength and better mechanical properties, making it ideal for structural components needing maximum durability. T5 temper, created by rapid cooling from an elevated temperature then artificially aged, offers good strength with improved dimensional stability, suitable for applications demanding precise machining and good surface finish.

T6 Temper vs T5 Temper Infographic

materialdif.com

materialdif.com