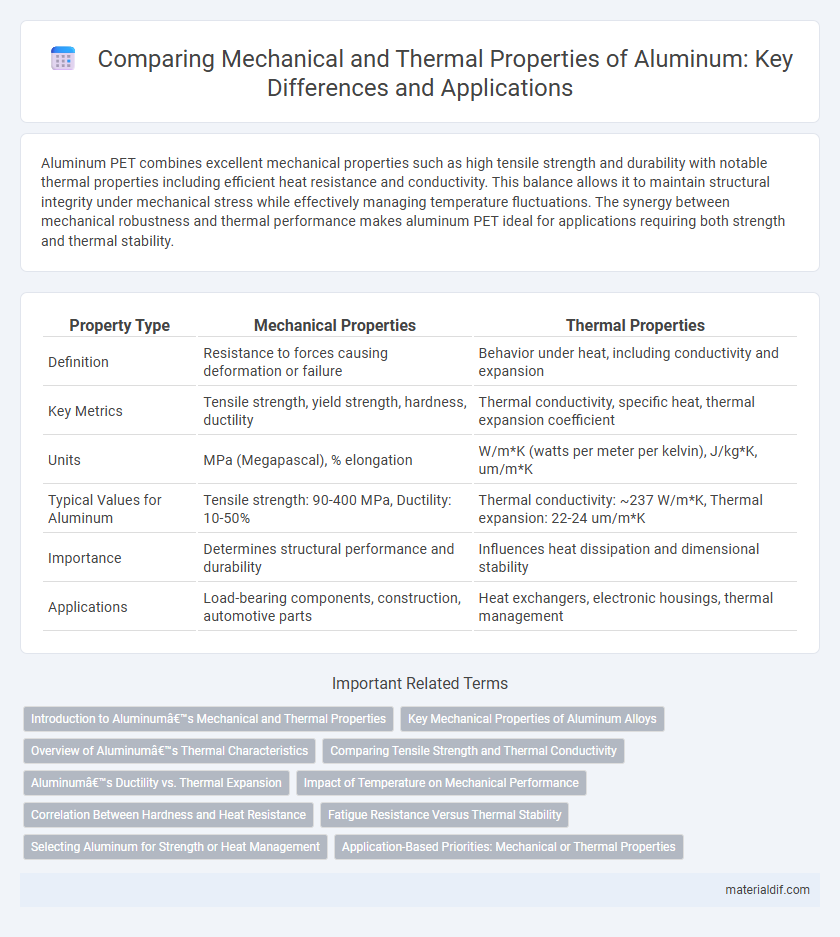

Aluminum PET combines excellent mechanical properties such as high tensile strength and durability with notable thermal properties including efficient heat resistance and conductivity. This balance allows it to maintain structural integrity under mechanical stress while effectively managing temperature fluctuations. The synergy between mechanical robustness and thermal performance makes aluminum PET ideal for applications requiring both strength and thermal stability.

Table of Comparison

| Property Type | Mechanical Properties | Thermal Properties |

|---|---|---|

| Definition | Resistance to forces causing deformation or failure | Behavior under heat, including conductivity and expansion |

| Key Metrics | Tensile strength, yield strength, hardness, ductility | Thermal conductivity, specific heat, thermal expansion coefficient |

| Units | MPa (Megapascal), % elongation | W/m*K (watts per meter per kelvin), J/kg*K, um/m*K |

| Typical Values for Aluminum | Tensile strength: 90-400 MPa, Ductility: 10-50% | Thermal conductivity: ~237 W/m*K, Thermal expansion: 22-24 um/m*K |

| Importance | Determines structural performance and durability | Influences heat dissipation and dimensional stability |

| Applications | Load-bearing components, construction, automotive parts | Heat exchangers, electronic housings, thermal management |

Introduction to Aluminum’s Mechanical and Thermal Properties

Aluminum exhibits a unique balance of mechanical properties such as high tensile strength and excellent ductility, making it ideal for structural applications. Its thermal properties include high thermal conductivity and low thermal expansion, enabling efficient heat dissipation and dimensional stability under temperature changes. Understanding the interplay between these mechanical and thermal characteristics is crucial for optimizing aluminum in aerospace, automotive, and construction industries.

Key Mechanical Properties of Aluminum Alloys

Aluminum alloys exhibit key mechanical properties including high tensile strength, excellent ductility, and impressive fatigue resistance, making them ideal for structural applications. Their yield strength ranges from 40 to 700 MPa depending on the alloy type and heat treatment, while the modulus of elasticity typically remains around 69 GPa. Thermal properties such as thermal conductivity vary widely, yet mechanical strength remains a critical factor for selecting aluminum alloys in environments requiring both durability and lightweight performance.

Overview of Aluminum’s Thermal Characteristics

Aluminum exhibits excellent thermal conductivity, typically around 205 W/m*K, making it highly efficient for heat dissipation applications compared to many other metals. Its low density combined with a melting point of approximately 660degC allows for versatile use in environments requiring both lightweight materials and reliable thermal resistance. Despite modest mechanical strength relative to steel, aluminum's thermal expansion coefficient near 23 x 10^-6 /degC necessitates careful consideration in design to manage dimensional changes under temperature fluctuations.

Comparing Tensile Strength and Thermal Conductivity

Aluminum exhibits a tensile strength ranging from 70 to 700 MPa depending on the alloy and treatment, while its thermal conductivity is typically around 205 W/m*K, which is significantly higher than many other metals. The high tensile strength in aerospace-grade aluminum alloys like 7075 provides structural durability, whereas the excellent thermal conductivity makes aluminum ideal for heat sinks and thermal management in electronics. This balance of mechanical robustness and efficient heat transfer distinguishes aluminum as a versatile material for applications requiring both strength and thermal performance.

Aluminum’s Ductility vs. Thermal Expansion

Aluminum exhibits exceptional ductility, allowing it to undergo significant plastic deformation without fracture, which is critical for applications requiring forming and bending. Its thermal expansion coefficient, approximately 23.1 x 10^-6 /degC, is relatively high compared to other metals, causing noticeable dimensional changes with temperature fluctuations. The combination of high ductility and notable thermal expansion makes aluminum ideal for components that must accommodate mechanical stress and thermal cycling.

Impact of Temperature on Mechanical Performance

Aluminum's mechanical properties, such as tensile strength and yield strength, significantly decline as temperature rises beyond 200degC due to increased atomic vibration and reduced dislocation resistance. Thermal properties, including thermal conductivity and expansion, influence the alloy's ability to dissipate heat efficiently, which directly affects its mechanical performance under thermal cycling. Elevated temperatures cause microstructural changes in aluminum alloys, leading to decreased hardness and fatigue resistance, critical considerations for high-temperature applications.

Correlation Between Hardness and Heat Resistance

Aluminum's hardness directly influences its heat resistance, as alloys with higher hardness typically exhibit enhanced thermal stability and reduced deformation at elevated temperatures. The correlation stems from the microstructural strengthening mechanisms that improve both mechanical rigidity and resistance to thermal softening. Optimizing aluminum's hardness through alloying and heat treatment enhances its performance in high-temperature applications such as aerospace and automotive components.

Fatigue Resistance Versus Thermal Stability

Aluminum alloys demonstrate excellent fatigue resistance due to their ability to withstand cyclic stress without significant crack propagation, making them ideal for structural applications. However, their thermal stability is relatively limited, as elevated temperatures can lead to grain growth and reduced mechanical strength. Optimizing aluminum compositions and heat treatments enhances both fatigue resistance and thermal stability for demanding engineering environments.

Selecting Aluminum for Strength or Heat Management

Aluminum's mechanical properties, such as high tensile strength and excellent ductility, make it ideal for applications requiring lightweight structural integrity. Its thermal properties, including high thermal conductivity and resistance to corrosion, suit heat management needs like heat exchangers or cooling systems. Selecting aluminum depends on prioritizing either mechanical strength for load-bearing uses or superior thermal performance for efficient heat dissipation.

Application-Based Priorities: Mechanical or Thermal Properties

In aluminum applications, the prioritization of mechanical or thermal properties depends on the specific use case, such as aerospace requiring high tensile strength and fatigue resistance versus heat exchangers demanding excellent thermal conductivity. Mechanical properties like yield strength and hardness are critical for structural components subjected to dynamic loads, while thermal conductivity and expansion coefficients govern performance in thermal management systems. Engineers select aluminum alloys based on the balance of these properties to optimize efficiency and durability in sectors ranging from automotive engineering to electronic cooling solutions.

Mechanical Properties vs Thermal Properties Infographic

materialdif.com

materialdif.com