Aluminum pipes are typically measured by their inside diameter and are designed for fluid transport, offering greater pressure resistance and durability in plumbing applications. Aluminum tubes are measured by outside diameter and are often used in structural and mechanical applications where precise dimensions and strength are critical. Understanding the difference in measurement standards and intended use helps in selecting the right aluminum conduit for specific industrial or construction needs.

Table of Comparison

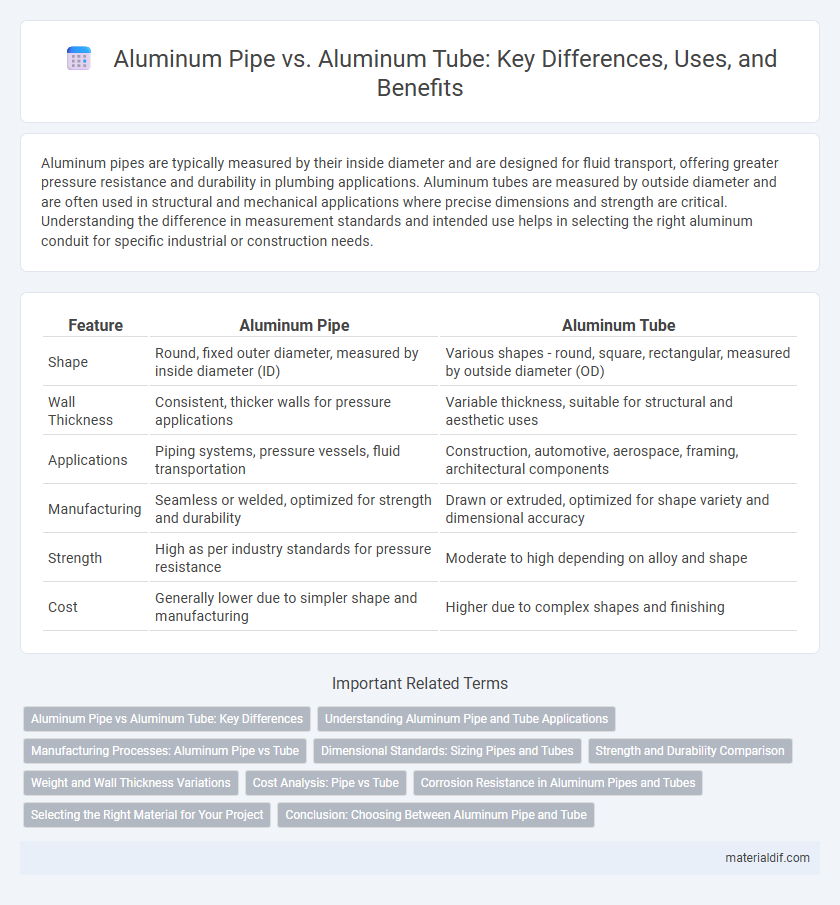

| Feature | Aluminum Pipe | Aluminum Tube |

|---|---|---|

| Shape | Round, fixed outer diameter, measured by inside diameter (ID) | Various shapes - round, square, rectangular, measured by outside diameter (OD) |

| Wall Thickness | Consistent, thicker walls for pressure applications | Variable thickness, suitable for structural and aesthetic uses |

| Applications | Piping systems, pressure vessels, fluid transportation | Construction, automotive, aerospace, framing, architectural components |

| Manufacturing | Seamless or welded, optimized for strength and durability | Drawn or extruded, optimized for shape variety and dimensional accuracy |

| Strength | High as per industry standards for pressure resistance | Moderate to high depending on alloy and shape |

| Cost | Generally lower due to simpler shape and manufacturing | Higher due to complex shapes and finishing |

Aluminum Pipe vs Aluminum Tube: Key Differences

Aluminum pipes are primarily designed for transporting fluids and gases with standardized dimensions based on nominal pipe size (NPS), ensuring compatibility with fittings and pressure ratings. Aluminum tubes offer more precise dimensions and are often used for structural applications, automotive parts, and aesthetic purposes, providing greater design flexibility. The key differences lie in their manufacturing tolerances, measurement standards, and intended uses, with pipes optimized for flow and pressure systems and tubes for strength and versatility.

Understanding Aluminum Pipe and Tube Applications

Aluminum pipes are primarily used for fluid transport and structural applications where precise measurements and pressure resistance are essential, making them ideal for plumbing, HVAC systems, and automotive exhausts. Aluminum tubes, with their varying shapes and wall thicknesses, offer versatility in manufacturing industries, including aerospace, construction, and furniture, providing strength, lightweight characteristics, and corrosion resistance. Understanding the specific requirements of a project, such as pressure tolerance and structural integrity, is crucial when choosing between aluminum pipes and tubes to ensure optimal performance and durability.

Manufacturing Processes: Aluminum Pipe vs Tube

Aluminum pipes are typically manufactured using extrusion or seamless processes, offering uniform wall thickness and high pressure resistance, ideal for fluid transportation. Aluminum tubes, produced through extrusion or drawing, emphasize precise dimensions and surface finish, making them suitable for structural and aesthetic applications. Differences in manufacturing impact the mechanical properties and cost-efficiency of aluminum pipes and tubes in industrial uses.

Dimensional Standards: Sizing Pipes and Tubes

Aluminum pipes adhere to nominal pipe size (NPS) and schedule standards that define their inner diameter and wall thickness for fluid transport applications. Aluminum tubes follow outside diameter (OD) and wall thickness specifications based on dimensional standards like ASTM B210 or ASTM B221, emphasizing precise measurements for structural and mechanical uses. Understanding these distinct sizing conventions ensures accurate selection and compatibility across industrial and construction projects.

Strength and Durability Comparison

Aluminum pipes typically feature thicker walls and are designed to withstand higher internal pressures, making them stronger and more durable for fluid transport applications. Aluminum tubes often have varied wall thicknesses and are engineered for structural uses, offering enhanced flexibility and corrosion resistance but slightly less strength under pressure. The strength and durability differences between aluminum pipe and tube depend largely on their alloy composition and manufacturing processes, with pipes generally excelling in high-pressure environments while tubes provide superior versatility in structural applications.

Weight and Wall Thickness Variations

Aluminum pipes typically feature thicker walls compared to aluminum tubes, providing enhanced strength and durability for heavy-duty applications. The weight of aluminum pipes is generally higher due to these increased wall thickness variations, which contribute to their ability to withstand higher pressure and stress. In contrast, aluminum tubes are lighter with thinner walls, making them ideal for lightweight structural or aesthetic uses where reduced weight is a priority.

Cost Analysis: Pipe vs Tube

Aluminum pipes generally cost less than aluminum tubes due to simpler manufacturing processes and less precise dimensional requirements. Tubes, with their tighter tolerances and enhanced strength, incur higher production costs but provide improved durability for specialized applications. Cost analysis must consider not only the initial material price but also specific project demands such as weight capacity and corrosion resistance.

Corrosion Resistance in Aluminum Pipes and Tubes

Aluminum pipes and tubes both exhibit excellent corrosion resistance due to their natural oxide layer that protects against rust and environmental damage. Pipes, typically used for fluid transport, often have thicker walls enhancing durability in corrosive environments, while tubes, with more precise dimensions, provide consistent resistance suitable for structural applications. The addition of alloys like magnesium or silicon can further improve corrosion resistance in specific aluminum pipe and tube products.

Selecting the Right Material for Your Project

Aluminum pipes and aluminum tubes differ primarily in shape and application, with pipes designed for transporting fluids under pressure, featuring standardized dimensions and thicker walls, while tubes offer versatility with precise measurements and varied shapes for structural or decorative uses. Selecting the right material depends on project requirements such as strength, corrosion resistance, and weight, where aluminum's lightweight and natural resistance to oxidation enhance performance in aerospace, automotive, and construction industries. Evaluating factors like load capacity, dimensional tolerances, and environmental conditions ensures optimal choice between aluminum pipe and tube for efficiency and durability.

Conclusion: Choosing Between Aluminum Pipe and Tube

Aluminum pipes are ideal for applications requiring high pressure resistance and fluid transport due to their standardized dimensions and thicker walls. Aluminum tubes offer greater flexibility in design with precision dimensions, making them suitable for structural and mechanical uses where customization and weight savings are critical. Selecting between aluminum pipe and tube depends on balancing strength requirements with application-specific performance and manufacturing standards.

Aluminum Pipe vs Aluminum Tube Infographic

materialdif.com

materialdif.com