Aluminum soldering involves joining aluminum parts using a filler metal with a lower melting point than the base metal, resulting in a bond without melting the aluminum itself, making it ideal for delicate or thin components. In contrast, aluminum welding melts the base aluminum and filler metal to create a strong, permanent joint suitable for structural applications where high strength and durability are required. Both techniques require specialized equipment and expertise to manage aluminum's thermal conductivity and oxide layer for optimal bonding.

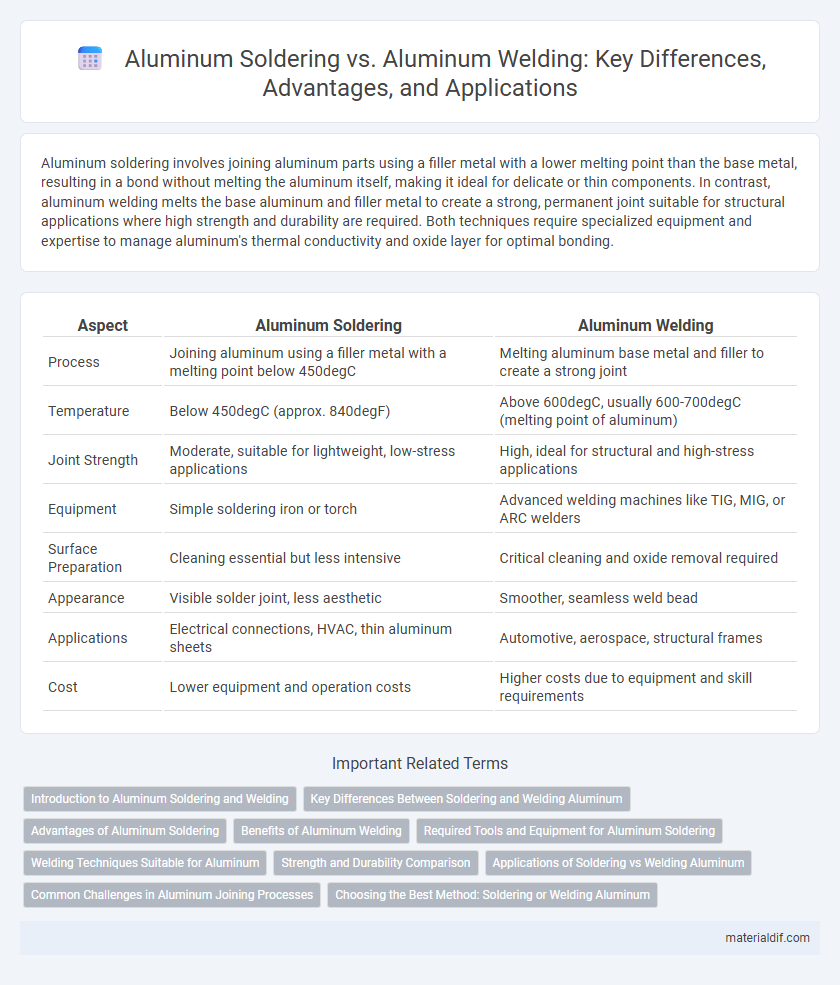

Table of Comparison

| Aspect | Aluminum Soldering | Aluminum Welding |

|---|---|---|

| Process | Joining aluminum using a filler metal with a melting point below 450degC | Melting aluminum base metal and filler to create a strong joint |

| Temperature | Below 450degC (approx. 840degF) | Above 600degC, usually 600-700degC (melting point of aluminum) |

| Joint Strength | Moderate, suitable for lightweight, low-stress applications | High, ideal for structural and high-stress applications |

| Equipment | Simple soldering iron or torch | Advanced welding machines like TIG, MIG, or ARC welders |

| Surface Preparation | Cleaning essential but less intensive | Critical cleaning and oxide removal required |

| Appearance | Visible solder joint, less aesthetic | Smoother, seamless weld bead |

| Applications | Electrical connections, HVAC, thin aluminum sheets | Automotive, aerospace, structural frames |

| Cost | Lower equipment and operation costs | Higher costs due to equipment and skill requirements |

Introduction to Aluminum Soldering and Welding

Aluminum soldering involves joining aluminum pieces using a filler metal with a lower melting point, typically requiring flux to prevent oxidation during the process. Aluminum welding, on the other hand, melts the base metal itself to create a strong, permanent joint, often utilizing techniques like TIG or MIG welding. Both methods demand specialized equipment and careful control of temperature due to aluminum's high thermal conductivity and oxide layer.

Key Differences Between Soldering and Welding Aluminum

Aluminum soldering involves joining aluminum pieces using a filler metal with a melting point below 450degC, requiring less heat and minimal base metal distortion, making it suitable for delicate or thin aluminum components. In contrast, aluminum welding melts the base metals along with the filler, creating a stronger, more permanent bond but necessitating higher temperatures and specialized equipment to prevent aluminum's oxidation and maintain joint integrity. The key difference lies in soldering's lower temperature process offering ease and precision, whereas welding delivers superior strength and durability for structural applications.

Advantages of Aluminum Soldering

Aluminum soldering offers advantages such as lower heat input, reducing the risk of warping or distorting thin aluminum components. It enables joining dissimilar metals with minimal thermal stress, preserving the integrity of sensitive materials. The process requires less energy and specialized equipment compared to aluminum welding, making it more cost-effective and accessible for delicate or precision applications.

Benefits of Aluminum Welding

Aluminum welding provides superior joint strength and durability compared to soldering, making it ideal for structural applications. It allows for seamless fusion of aluminum parts, resulting in enhanced electrical and thermal conductivity. Welding also accommodates thicker sections and complex geometries, which soldering cannot reliably achieve.

Required Tools and Equipment for Aluminum Soldering

Aluminum soldering requires a soldering iron or torch, special flux designed for aluminum, and aluminum-compatible solder wire to ensure strong, corrosion-resistant joints. Surface preparation tools such as wire brushes and sandpaper are essential for cleaning oxides and promoting solder adhesion. Unlike welding, soldering demands precise temperature control and protective equipment to avoid overheating and damage to the aluminum substrate.

Welding Techniques Suitable for Aluminum

TIG welding and MIG welding are the most effective welding techniques for aluminum due to their ability to produce strong, clean welds on this lightweight metal. TIG welding provides precise heat control, making it ideal for thin aluminum sheets, while MIG welding allows faster welding on thicker sections. Proper shielding gas, usually pure argon or an argon-helium mix, is essential to prevent oxidation and ensure high-quality welds.

Strength and Durability Comparison

Aluminum soldering offers lower joint strength and durability compared to aluminum welding, with tensile strengths typically ranging between 15,000 to 25,000 psi versus welding's strength exceeding 35,000 psi. Welding creates a metallurgical bond that fuses aluminum at a molecular level, resulting in superior mechanical properties and resistance to fatigue and corrosion. Soldered joints are more prone to failure under stress and high temperatures, making welding the preferred method for structural and load-bearing aluminum applications.

Applications of Soldering vs Welding Aluminum

Aluminum soldering is commonly used in electronic components, HVAC systems, and thin-gauge aluminum sheets where precise, low-heat joining is essential to prevent warping. In contrast, aluminum welding is preferred for structural applications such as automotive frames, aerospace parts, and heavy machinery due to its strong, durable joints that withstand high stress and load. Welding aluminum forms a metallurgical bond suitable for load-bearing applications, whereas soldering provides electrical conductivity and corrosion resistance for delicate assemblies.

Common Challenges in Aluminum Joining Processes

Aluminum soldering and welding present common challenges such as oxide layer formation and thermal distortion, which hinder proper joint formation. The high thermal conductivity of aluminum causes rapid heat dissipation, requiring precise temperature control to avoid weak joints or warping. Additionally, controlling alloy composition and minimizing porosity are critical to achieving strong, reliable connections in both soldering and welding processes.

Choosing the Best Method: Soldering or Welding Aluminum

Choosing between aluminum soldering and aluminum welding depends on factors such as joint strength requirements, thermal conductivity, and application specifics. Welding creates strong, durable joints through melting and fusion, ideal for structural or high-stress aluminum components, while soldering uses a lower temperature process with filler metals, suitable for delicate or thin aluminum parts requiring electrical conductivity or minimal heat distortion. Consider the aluminum alloy type, environmental conditions, and desired finish to select the optimal method for performance and longevity.

Aluminum Soldering vs Aluminum Welding Infographic

materialdif.com

materialdif.com