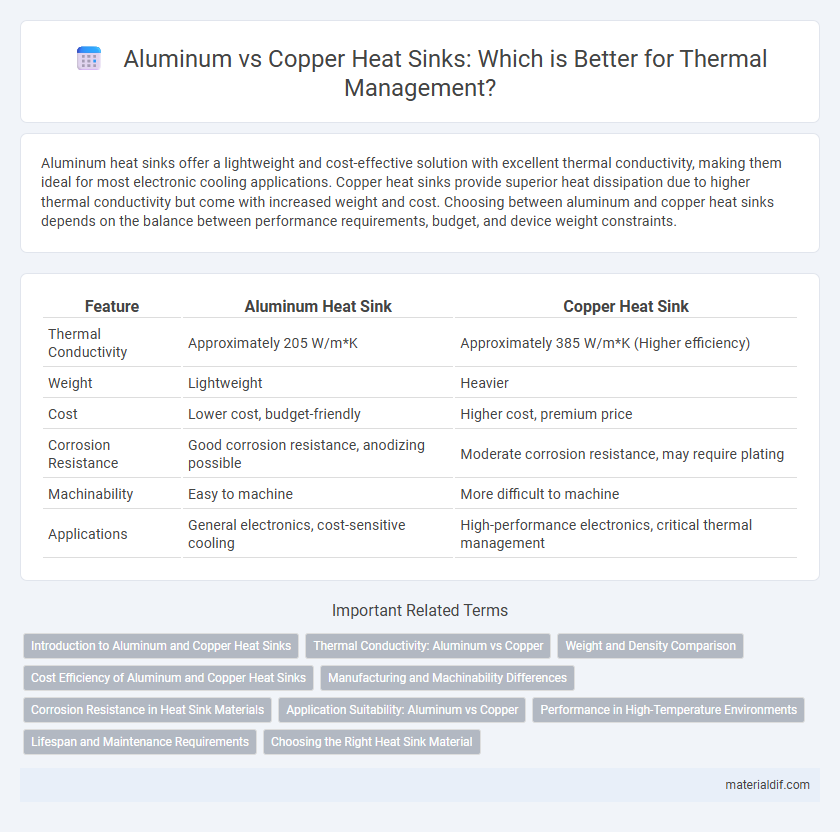

Aluminum heat sinks offer a lightweight and cost-effective solution with excellent thermal conductivity, making them ideal for most electronic cooling applications. Copper heat sinks provide superior heat dissipation due to higher thermal conductivity but come with increased weight and cost. Choosing between aluminum and copper heat sinks depends on the balance between performance requirements, budget, and device weight constraints.

Table of Comparison

| Feature | Aluminum Heat Sink | Copper Heat Sink |

|---|---|---|

| Thermal Conductivity | Approximately 205 W/m*K | Approximately 385 W/m*K (Higher efficiency) |

| Weight | Lightweight | Heavier |

| Cost | Lower cost, budget-friendly | Higher cost, premium price |

| Corrosion Resistance | Good corrosion resistance, anodizing possible | Moderate corrosion resistance, may require plating |

| Machinability | Easy to machine | More difficult to machine |

| Applications | General electronics, cost-sensitive cooling | High-performance electronics, critical thermal management |

Introduction to Aluminum and Copper Heat Sinks

Aluminum heat sinks are widely used in electronic cooling due to their excellent thermal conductivity, lightweight nature, and cost-effectiveness, typically offering thermal conductivity around 205 W/m*K. Copper heat sinks provide superior thermal performance with thermal conductivity approximately 385 W/m*K, making them ideal for high-performance cooling applications despite their heavier weight and higher cost. Both materials are chosen based on specific cooling requirements, balancing efficiency, durability, and budget constraints.

Thermal Conductivity: Aluminum vs Copper

Copper exhibits thermal conductivity of approximately 400 W/m*K, significantly higher than aluminum's 205 W/m*K, making copper heat sinks more efficient at dissipating heat. Aluminum, although having lower thermal conductivity, offers advantages in weight and cost, which are critical in many electronic cooling applications. The choice between aluminum and copper heat sinks depends on balancing thermal performance with material properties such as weight and price.

Weight and Density Comparison

Aluminum heat sinks are significantly lighter than copper heat sinks due to aluminum's density of approximately 2.7 g/cm3 compared to copper's density of around 8.96 g/cm3. This lower density makes aluminum heat sinks ideal for applications requiring weight reduction without compromising thermal performance. While copper offers superior thermal conductivity, aluminum's balance of lightweight and adequate heat dissipation makes it a popular choice in electronics cooling.

Cost Efficiency of Aluminum and Copper Heat Sinks

Aluminum heat sinks offer superior cost efficiency due to their lower raw material price and reduced manufacturing expenses compared to copper heat sinks. While copper provides better thermal conductivity, the higher cost of copper drives up total production costs, making aluminum the preferred choice for budget-sensitive applications. This makes aluminum heat sinks ideal for large-scale electronics cooling where cost reduction is critical without significantly compromising performance.

Manufacturing and Machinability Differences

Aluminum heat sinks offer superior machinability due to their lower melting point and softer metal properties, enabling faster manufacturing cycles and reduced tooling wear compared to copper. Copper heat sinks, while providing better thermal conductivity, present challenges in machining such as increased tool wear and longer production times due to their hardness and high melting temperature. The choice between aluminum and copper heat sinks significantly impacts manufacturing efficiency, cost, and scalability in thermal management solutions.

Corrosion Resistance in Heat Sink Materials

Aluminum heat sinks offer superior corrosion resistance due to the natural formation of a protective oxide layer that prevents further oxidation, making them ideal for environments with moisture and varying temperatures. Copper heat sinks, while excellent in thermal conductivity, are more prone to corrosion, especially in acidic or chloride-rich conditions, which can degrade performance over time. Selecting aluminum heat sinks provides long-term durability and maintains thermal efficiency in corrosive environments, reducing maintenance and replacement costs.

Application Suitability: Aluminum vs Copper

Aluminum heat sinks are highly suitable for applications requiring lightweight and cost-effective thermal management, such as in consumer electronics and LED lighting, due to their excellent thermal conductivity and corrosion resistance. Copper heat sinks excel in high-performance systems like power supplies and industrial equipment where superior thermal conductivity and heat dissipation are critical, despite their higher weight and cost. Choosing between aluminum and copper heat sinks depends on balancing the application's thermal demands, budget constraints, and weight considerations.

Performance in High-Temperature Environments

Aluminum heat sinks offer excellent thermal conductivity of around 205 W/mK, making them efficient for moderate high-temperature environments while being lightweight and corrosion-resistant. Copper heat sinks provide superior thermal performance with a conductivity of approximately 385 W/mK, allowing better heat dissipation in extreme high-temperature applications, albeit with higher weight and cost. In high-temperature scenarios above 150degC, copper heat sinks maintain performance and structural integrity longer, while aluminum may experience reduced efficiency and potential oxidation.

Lifespan and Maintenance Requirements

Aluminum heat sinks offer superior corrosion resistance, contributing to a longer lifespan in environments prone to oxidation compared to copper heat sinks that can tarnish and require more frequent maintenance. Aluminum's lightweight nature reduces stress on mounting hardware, minimizing mechanical wear over time and lowering overall maintenance demands. Although copper provides excellent thermal conductivity, its susceptibility to oxidation and heavier weight often result in higher maintenance needs and potentially shorter effective lifespan.

Choosing the Right Heat Sink Material

Aluminum heat sinks offer excellent thermal conductivity at a lower cost and weight compared to copper, making them ideal for applications where cost-efficiency and weight reduction are crucial. Copper heat sinks provide superior heat dissipation due to higher thermal conductivity, making them suitable for high-performance electronics requiring maximum cooling. Selecting the right heat sink material depends on balancing factors such as thermal performance, budget, weight constraints, and specific device cooling requirements.

Aluminum Heat Sink vs Copper Heat Sink Infographic

materialdif.com

materialdif.com