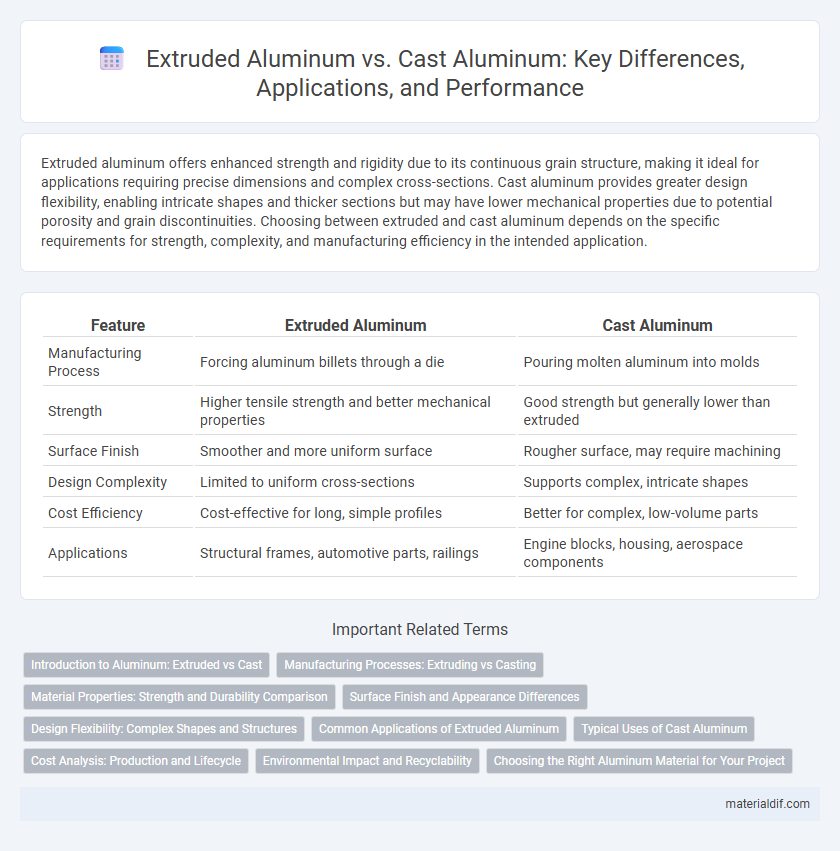

Extruded aluminum offers enhanced strength and rigidity due to its continuous grain structure, making it ideal for applications requiring precise dimensions and complex cross-sections. Cast aluminum provides greater design flexibility, enabling intricate shapes and thicker sections but may have lower mechanical properties due to potential porosity and grain discontinuities. Choosing between extruded and cast aluminum depends on the specific requirements for strength, complexity, and manufacturing efficiency in the intended application.

Table of Comparison

| Feature | Extruded Aluminum | Cast Aluminum |

|---|---|---|

| Manufacturing Process | Forcing aluminum billets through a die | Pouring molten aluminum into molds |

| Strength | Higher tensile strength and better mechanical properties | Good strength but generally lower than extruded |

| Surface Finish | Smoother and more uniform surface | Rougher surface, may require machining |

| Design Complexity | Limited to uniform cross-sections | Supports complex, intricate shapes |

| Cost Efficiency | Cost-effective for long, simple profiles | Better for complex, low-volume parts |

| Applications | Structural frames, automotive parts, railings | Engine blocks, housing, aerospace components |

Introduction to Aluminum: Extruded vs Cast

Extruded aluminum is produced by forcing heated aluminum billet through a shaped die, resulting in long, continuous profiles with uniform cross-sections ideal for structural applications. Cast aluminum is formed by pouring molten aluminum into molds, creating complex shapes with varied thicknesses, commonly used for detailed parts like engine components. The extrusion process offers better mechanical properties and surface finish, while casting allows for intricate designs and cost-effective production of complex forms.

Manufacturing Processes: Extruding vs Casting

Extruded aluminum involves forcing heated aluminum billet through a shaped die to create uniform cross-sectional profiles, enabling precise control over dimensions and enhanced mechanical properties through work hardening. Cast aluminum is produced by melting aluminum and pouring it into molds, allowing complex shapes and thicker sections but often resulting in coarser grain structures and lower strength compared to extruded parts. The choice between extruding and casting depends on design complexity, tolerances, and structural requirements, with extrusion favored for linear, high-strength applications and casting preferred for intricate geometries.

Material Properties: Strength and Durability Comparison

Extruded aluminum exhibits superior strength and durability due to its grain structure, which is aligned during the extrusion process, enhancing tensile strength and resistance to impact. Cast aluminum, while offering complex shapes, generally has a coarser grain structure that can lead to lower mechanical strength and increased porosity, affecting long-term durability. The choice between extruded and cast aluminum depends on application requirements, with extrusions preferred for structural components requiring higher strength and castings favored for intricate designs with moderate strength needs.

Surface Finish and Appearance Differences

Extruded aluminum exhibits a smooth, uniform surface finish with fine lines running parallel due to the continuous shaping process, ideal for applications requiring consistent and clean aesthetics. Cast aluminum often has a rougher texture and may display minor surface imperfections or porosity from the mold, resulting in a less polished appearance but allowing for complex shapes and detailed designs. Surface finishing techniques like anodizing or powder coating can enhance appearance, yet extruded aluminum generally offers superior natural surface uniformity compared to cast aluminum.

Design Flexibility: Complex Shapes and Structures

Extruded aluminum offers superior design flexibility for creating complex shapes and structures due to its ability to form continuous cross-sectional profiles with intricate geometries. Cast aluminum allows for even more complex and detailed three-dimensional shapes by filling molds, making it ideal for components requiring intricate internal features or hollow sections. Both methods provide unique advantages, with extrusion excelling in uniformity and strength along the length, while casting enables highly customized, elaborate designs not achievable through extrusion.

Common Applications of Extruded Aluminum

Extruded aluminum is widely used in construction for window frames, door frames, and curtain walls due to its strength, lightweight, and design flexibility. Its excellent corrosion resistance makes it ideal for transportation components such as automotive parts, aerospace structures, and rail vehicles. Industrial applications include heat sinks, electrical enclosures, and machinery parts where precise cross-sectional profiles and enhanced mechanical properties are required.

Typical Uses of Cast Aluminum

Cast aluminum is commonly used in automotive parts, such as engine blocks and cylinder heads, where complex shapes and excellent strength-to-weight ratios are essential. It is also widely applied in the manufacturing of machinery components and aerospace parts due to its superior thermal conductivity and corrosion resistance. Home appliances and decorative items benefit from cast aluminum's ability to produce detailed, high-quality finishes while maintaining durability.

Cost Analysis: Production and Lifecycle

Extruded aluminum typically offers lower production costs due to faster manufacturing cycles and less material waste compared to cast aluminum, making it ideal for high-volume applications. Cast aluminum involves higher initial tooling expenses and longer cooling times but provides complex shapes with reduced machining, impacting lifecycle costs favorably in custom or low-volume production. Considering maintenance and recyclability, extruded aluminum often results in lower lifecycle costs, while cast aluminum can deliver cost-efficiency through enhanced durability in specific structural uses.

Environmental Impact and Recyclability

Extruded aluminum demonstrates a lower environmental impact due to its energy-efficient manufacturing process that minimizes waste compared to cast aluminum, which typically requires higher melting temperatures and more energy consumption. Both extruded and cast aluminum offer excellent recyclability, with recycled aluminum retaining its properties indefinitely and requiring up to 95% less energy than producing primary aluminum. The choice between extruded and cast aluminum should factor in lifecycle carbon footprints and recycling infrastructure to optimize sustainability outcomes.

Choosing the Right Aluminum Material for Your Project

Extruded aluminum offers superior strength and precision for complex cross-sectional designs, making it ideal for structural components and custom profiles. Cast aluminum provides greater design flexibility and is well-suited for intricate shapes and thicker sections, often used in machinery parts and automotive applications. Selecting the right aluminum material depends on project requirements, including mechanical strength, surface finish, and production volume.

Extruded Aluminum vs Cast Aluminum Infographic

materialdif.com

materialdif.com