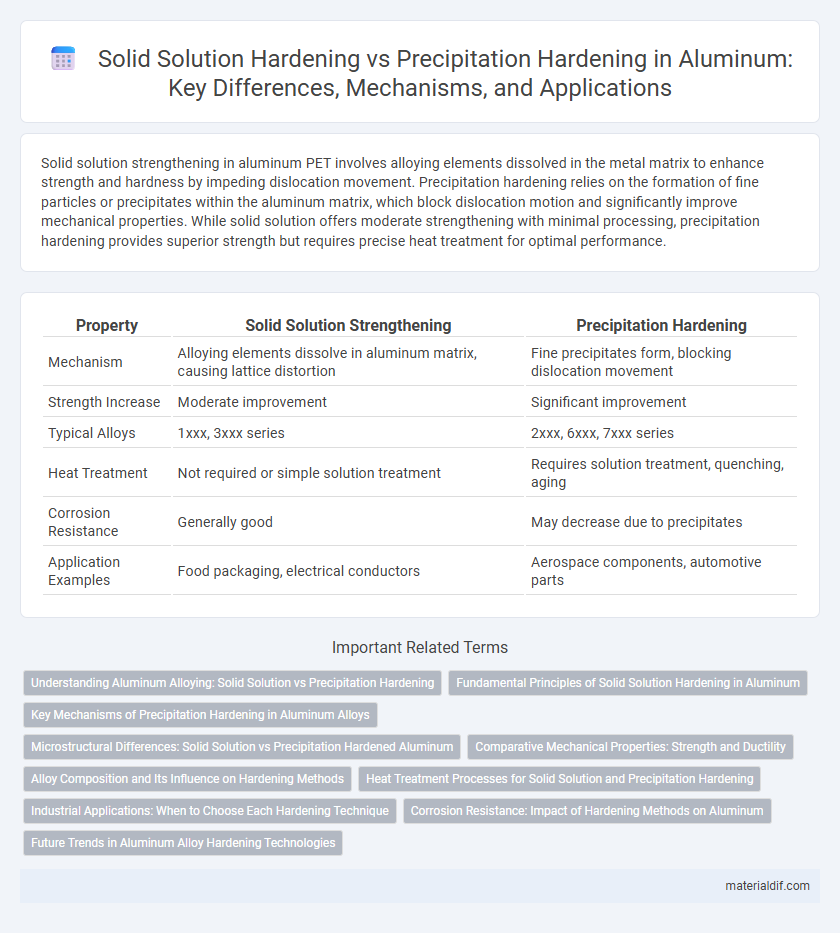

Solid solution strengthening in aluminum PET involves alloying elements dissolved in the metal matrix to enhance strength and hardness by impeding dislocation movement. Precipitation hardening relies on the formation of fine particles or precipitates within the aluminum matrix, which block dislocation motion and significantly improve mechanical properties. While solid solution offers moderate strengthening with minimal processing, precipitation hardening provides superior strength but requires precise heat treatment for optimal performance.

Table of Comparison

| Property | Solid Solution Strengthening | Precipitation Hardening |

|---|---|---|

| Mechanism | Alloying elements dissolve in aluminum matrix, causing lattice distortion | Fine precipitates form, blocking dislocation movement |

| Strength Increase | Moderate improvement | Significant improvement |

| Typical Alloys | 1xxx, 3xxx series | 2xxx, 6xxx, 7xxx series |

| Heat Treatment | Not required or simple solution treatment | Requires solution treatment, quenching, aging |

| Corrosion Resistance | Generally good | May decrease due to precipitates |

| Application Examples | Food packaging, electrical conductors | Aerospace components, automotive parts |

Understanding Aluminum Alloying: Solid Solution vs Precipitation Hardening

Solid solution strengthening in aluminum alloys involves dissolving alloying elements like magnesium or silicon into the aluminum matrix, creating lattice distortions that impede dislocation movement and increase strength. Precipitation hardening, or age hardening, occurs when fine, dispersed particles such as Al3Li or Mg2Si precipitate from a supersaturated solid solution during controlled heat treatment, significantly enhancing hardness and mechanical properties. Understanding the balance between these mechanisms is crucial for optimizing aluminum alloy performance in aerospace, automotive, and structural applications.

Fundamental Principles of Solid Solution Hardening in Aluminum

Solid solution hardening in aluminum occurs when alloying elements such as copper, magnesium, or zinc are dissolved into the aluminum matrix, causing lattice distortions that impede dislocation movement and increase strength. The effectiveness of solid solution hardening depends on factors like atomic size mismatch, concentration of solute atoms, and modulus differences between solute and solvent atoms. This mechanism contrasts with precipitation hardening, where strength enhancement results from the formation of fine, dispersed intermetallic particles that block dislocations in the aluminum alloy.

Key Mechanisms of Precipitation Hardening in Aluminum Alloys

Precipitation hardening in aluminum alloys involves the controlled formation of fine precipitates, such as Mg2Si or Al3Sc, within the aluminum matrix, which impede dislocation movement and significantly enhance strength. This process typically includes solution treatment, quenching, and aging, where supersaturated solid solutions decompose to form coherent or semi-coherent precipitates that create lattice strain fields blocking dislocation glide. Unlike solid solution strengthening, which relies on atomic size mismatch and elastic strain, precipitation hardening leverages the nucleation and growth of secondary phases to achieve superior mechanical properties in aluminum alloys.

Microstructural Differences: Solid Solution vs Precipitation Hardened Aluminum

Solid solution hardening in aluminum involves the uniform distribution of alloying elements within the aluminum matrix, resulting in lattice distortion that impedes dislocation motion. Precipitation hardening creates fine, dispersed secondary phase particles within the aluminum matrix, which serve as obstacles to dislocation movement and significantly enhance strength. Microstructurally, solid solution aluminum exhibits a homogeneous single-phase structure, while precipitation hardened aluminum displays distinct precipitate phases that refine grain boundaries and improve mechanical properties.

Comparative Mechanical Properties: Strength and Ductility

Solid solution strengthening in aluminum alloys enhances strength by dissolving alloying elements within the crystal lattice, resulting in moderate strength improvement while maintaining high ductility. Precipitation hardening yields significantly higher strength through the formation of fine, dispersed precipitates that obstruct dislocation motion, though it can reduce ductility due to increased brittleness. Comparing mechanical properties, precipitation-hardened aluminum alloys generally exhibit superior tensile strength but lower ductility compared to solid solution strengthened alloys, making the choice dependent on specific performance requirements.

Alloy Composition and Its Influence on Hardening Methods

Aluminum alloys with higher solute content, such as those containing magnesium or copper, respond effectively to solid solution strengthening by dissolving atoms within the aluminum matrix, enhancing hardness and tensile strength. In contrast, precipitation hardening alloys rely on precise alloy compositions, typically with elements like copper, zinc, and magnesium, that form fine, dispersed precipitates during heat treatment, significantly increasing yield strength. The specific alloying elements and their concentrations dictate the dominance of solid solution strengthening or precipitation hardening, influencing mechanical properties and application performance.

Heat Treatment Processes for Solid Solution and Precipitation Hardening

Heat treatment for solid solution strengthening in aluminum involves homogenization at high temperatures followed by rapid quenching to retain a supersaturated solid solution, enhancing strength by solute atom interaction with dislocations. Precipitation hardening heat treatment includes solution treatment, quenching, and aging, where fine precipitates form during aging to impede dislocation movement, significantly increasing hardness and mechanical properties. Controlled temperature and time during aging are critical in precipitation hardening to optimize precipitate size, distribution, and alloy performance.

Industrial Applications: When to Choose Each Hardening Technique

Solid solution strengthening in aluminum alloys is ideal for applications requiring moderate strength with excellent corrosion resistance, such as aerospace components and automotive body panels. Precipitation hardening provides higher strength and hardness, making it suitable for structural parts in aircraft, high-performance automotive engines, and aerospace fasteners. Selecting between these techniques depends on the specific mechanical property demands and operating environments of the industrial application.

Corrosion Resistance: Impact of Hardening Methods on Aluminum

Solid solution strengthening enhances aluminum's corrosion resistance by promoting a uniform distribution of alloying elements, which stabilizes the passive oxide layer and reduces localized attack. Precipitation hardening can sometimes decrease corrosion resistance due to the formation of anodic precipitates that act as sites for pitting and intergranular corrosion. Optimizing alloy composition and heat treatment is crucial to balance mechanical strength with enhanced corrosion resistance in aluminum alloys.

Future Trends in Aluminum Alloy Hardening Technologies

Emerging trends in aluminum alloy hardening technologies emphasize the integration of advanced solid solution strengthening with nano-precipitation hardening techniques to achieve superior mechanical properties. Research is focusing on optimizing alloy composition at the atomic scale using machine learning models to enhance phase stability and precipitation kinetics. Future developments aim to create multifunctional aluminum alloys with improved strength, corrosion resistance, and thermal stability for aerospace and automotive applications.

Solid Solution vs Precipitation Hardening Infographic

materialdif.com

materialdif.com