Aluminum foam offers superior energy absorption and lightweight properties, making it ideal for impact protection and sound insulation in automotive and aerospace applications. Aluminum honeycomb provides exceptional structural strength and stiffness while maintaining low weight, commonly used in aerospace panels and wind turbine blades. Choosing between aluminum foam and honeycomb depends on specific needs for cushioning versus load-bearing performance.

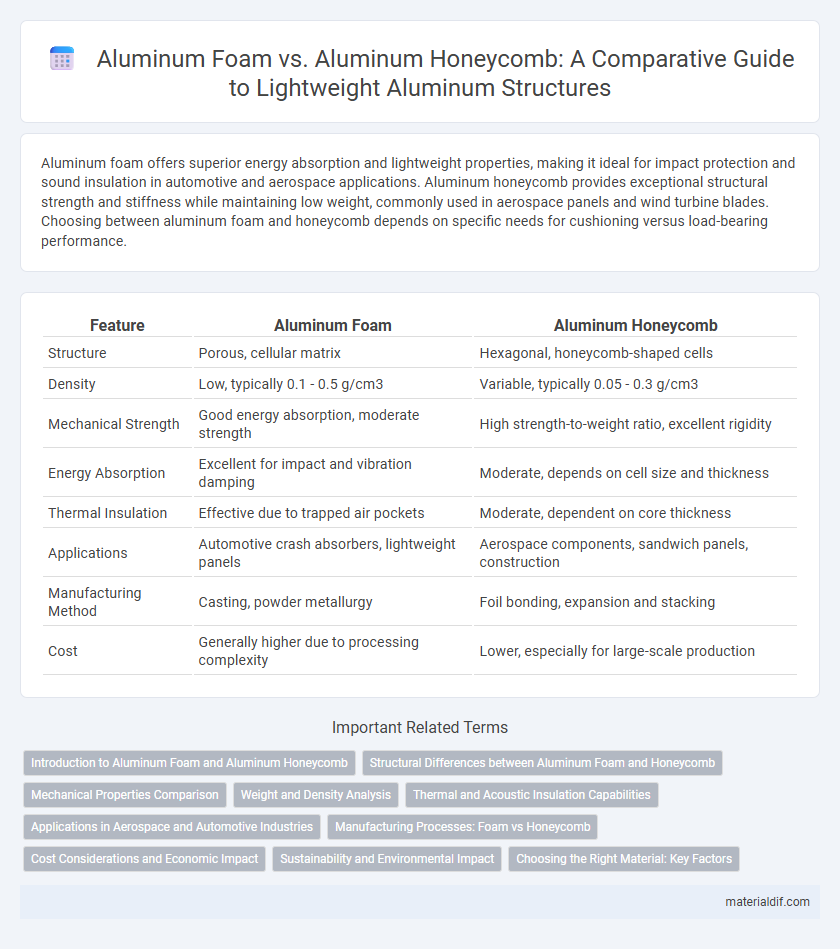

Table of Comparison

| Feature | Aluminum Foam | Aluminum Honeycomb |

|---|---|---|

| Structure | Porous, cellular matrix | Hexagonal, honeycomb-shaped cells |

| Density | Low, typically 0.1 - 0.5 g/cm3 | Variable, typically 0.05 - 0.3 g/cm3 |

| Mechanical Strength | Good energy absorption, moderate strength | High strength-to-weight ratio, excellent rigidity |

| Energy Absorption | Excellent for impact and vibration damping | Moderate, depends on cell size and thickness |

| Thermal Insulation | Effective due to trapped air pockets | Moderate, dependent on core thickness |

| Applications | Automotive crash absorbers, lightweight panels | Aerospace components, sandwich panels, construction |

| Manufacturing Method | Casting, powder metallurgy | Foil bonding, expansion and stacking |

| Cost | Generally higher due to processing complexity | Lower, especially for large-scale production |

Introduction to Aluminum Foam and Aluminum Honeycomb

Aluminum foam is a lightweight, porous material consisting of a cellular structure created by trapping gas bubbles within molten aluminum, resulting in high energy absorption and excellent thermal insulation properties. Aluminum honeycomb features a hexagonal core structure bonded between aluminum sheets, providing exceptional strength-to-weight ratio and superior mechanical performance under compressive loads. Both materials are extensively used in aerospace, automotive, and construction industries for impact resistance and weight reduction applications.

Structural Differences between Aluminum Foam and Honeycomb

Aluminum foam consists of a porous, cellular structure with interconnected air pockets, providing lightweight characteristics and excellent energy absorption capabilities. In contrast, aluminum honeycomb features a rigid, hexagonal cell pattern offering high compressive strength and stability with minimal weight. The foam's isotropic properties differ from the honeycomb's anisotropic nature, affecting load distribution and mechanical performance in structural applications.

Mechanical Properties Comparison

Aluminum foam exhibits superior energy absorption and impact resistance due to its porous structure, making it ideal for cushioning and crash protection applications. Aluminum honeycomb offers higher compressive strength and stiffness with a lightweight design, providing excellent load-bearing capabilities in aerospace and automotive structures. Both materials deliver unique mechanical advantages, with aluminum foam excelling in damping and honeycomb in structural support.

Weight and Density Analysis

Aluminum foam exhibits significantly lower density ranging from 0.2 to 0.8 g/cm3, making it ideal for ultra-lightweight applications, while aluminum honeycomb typically has a density between 0.5 and 2.0 g/cm3, offering a balance between weight and structural strength. Weight analysis shows aluminum foam provides greater energy absorption at reduced mass, whereas aluminum honeycomb delivers higher load-bearing capacity at moderate weight. Density variation directly influences mechanical properties, with foam's porous structure leading to exceptional weight savings and honeycomb's cellular design enhancing stiffness and durability.

Thermal and Acoustic Insulation Capabilities

Aluminum foam exhibits superior thermal insulation due to its porous structure, which traps air and reduces heat transfer more effectively than the denser aluminum honeycomb. Acoustic insulation is also enhanced in aluminum foam, as its irregular cell walls absorb sound waves better compared to the uniform structure of honeycomb panels. While aluminum honeycomb offers strength and lightweight characteristics, aluminum foam excels in applications requiring advanced thermal and acoustic performance.

Applications in Aerospace and Automotive Industries

Aluminum foam offers exceptional energy absorption and lightweight properties ideal for automotive crash structures and aerospace impact protection. Aluminum honeycomb provides superior strength-to-weight ratios and stiffness, making it suitable for aircraft fuselage panels and automotive chassis components. Both materials enhance fuel efficiency and safety in aerospace and automotive designs through optimized structural performance.

Manufacturing Processes: Foam vs Honeycomb

Aluminum foam is produced through processes such as powder metallurgy, aluminum casting with gas injection, or foaming agents to create a porous structure, while aluminum honeycomb is manufactured by bonding thin aluminum sheets into hexagonal cells using adhesive bonding or brazing techniques. The foam manufacturing process involves melting and gas expansion or powder sintering to achieve its lightweight and energy-absorbing properties, whereas honeycomb production emphasizes precise sheet forming and cell geometry control for optimal structural strength and rigidity. These distinct fabrication methods result in different mechanical characteristics, making aluminum foam ideal for impact absorption and aluminum honeycomb preferred for load-bearing and lightweight structural applications.

Cost Considerations and Economic Impact

Aluminum foam typically incurs higher production costs due to its complex manufacturing processes involving gas injection or powder metallurgy, making it less economical for large-scale applications compared to aluminum honeycomb. Aluminum honeycomb structures offer cost advantages by utilizing simpler extrusion and expansion techniques, resulting in lower material and fabrication expenses. Economically, aluminum honeycomb is preferred in industries such as aerospace and automotive for cost-sensitive projects, whereas aluminum foam is chosen for specialized applications requiring superior energy absorption despite higher costs.

Sustainability and Environmental Impact

Aluminum foam offers superior sustainability through its lightweight structure and high recyclability, reducing resource consumption and energy use in production. Compared to aluminum honeycomb, aluminum foam provides enhanced energy absorption and thermal insulation, leading to lower carbon emissions during the product lifecycle. Both materials support circular economy principles, but aluminum foam's ease of recycling and reduced waste generation make it a more environmentally friendly option.

Choosing the Right Material: Key Factors

When selecting between aluminum foam and aluminum honeycomb, consider factors such as weight, energy absorption, and structural requirements. Aluminum foam offers superior impact resistance and sound absorption, making it ideal for vibration damping and crash protection, while aluminum honeycomb provides excellent stiffness-to-weight ratio suited for aerospace and automotive structural panels. Evaluate application-specific demands including load-bearing capacity, thermal insulation, and durability to determine the optimal lightweight material.

Aluminum Foam vs Aluminum Honeycomb Infographic

materialdif.com

materialdif.com