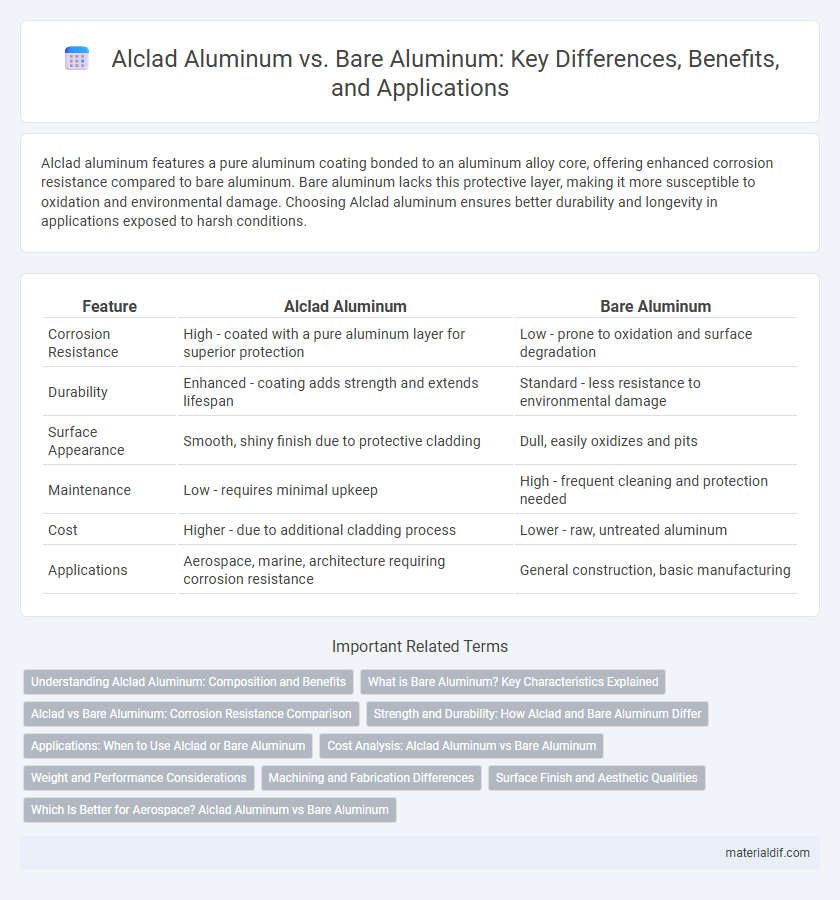

Alclad aluminum features a pure aluminum coating bonded to an aluminum alloy core, offering enhanced corrosion resistance compared to bare aluminum. Bare aluminum lacks this protective layer, making it more susceptible to oxidation and environmental damage. Choosing Alclad aluminum ensures better durability and longevity in applications exposed to harsh conditions.

Table of Comparison

| Feature | Alclad Aluminum | Bare Aluminum |

|---|---|---|

| Corrosion Resistance | High - coated with a pure aluminum layer for superior protection | Low - prone to oxidation and surface degradation |

| Durability | Enhanced - coating adds strength and extends lifespan | Standard - less resistance to environmental damage |

| Surface Appearance | Smooth, shiny finish due to protective cladding | Dull, easily oxidizes and pits |

| Maintenance | Low - requires minimal upkeep | High - frequent cleaning and protection needed |

| Cost | Higher - due to additional cladding process | Lower - raw, untreated aluminum |

| Applications | Aerospace, marine, architecture requiring corrosion resistance | General construction, basic manufacturing |

Understanding Alclad Aluminum: Composition and Benefits

Alclad aluminum consists of a core aluminum alloy bonded between high-purity aluminum layers, providing superior corrosion resistance compared to bare aluminum. The outer aluminum cladding protects the alloy core from oxidation and environmental damage while retaining the strength and lightweight properties of the core material. This composition makes Alclad aluminum ideal for aerospace applications where durability and resistance to corrosion are critical.

What is Bare Aluminum? Key Characteristics Explained

Bare aluminum refers to aluminum in its pure, untreated state without any protective coatings or finishes, exposing the natural metal surface. Key characteristics of bare aluminum include high corrosion susceptibility, especially in humid or marine environments, as it lacks the protective oxide layer enhanced by coatings. Its lightweight nature and excellent thermal and electrical conductivity remain unchanged, but the absence of surface protection requires careful handling to prevent oxidation and surface damage.

Alclad vs Bare Aluminum: Corrosion Resistance Comparison

Alclad aluminum offers superior corrosion resistance compared to bare aluminum due to its layered construction, which includes a pure aluminum outer coating that protects the underlying aluminum alloy from oxidizing and pitting. The pure aluminum layer in Alclad acts as a sacrificial barrier, significantly enhancing durability and longevity in corrosive environments such as marine or industrial settings. Bare aluminum lacks this protective coating, making it more susceptible to corrosion and requiring additional treatments for long-term exposure resistance.

Strength and Durability: How Alclad and Bare Aluminum Differ

Alclad aluminum features a high-strength core alloy bonded with thin layers of pure aluminum, enhancing corrosion resistance without compromising structural integrity. Bare aluminum, while lighter, lacks the protective cladding, making it more susceptible to environmental degradation and reduced longevity. The fusion in Alclad offers superior durability in aerospace and marine applications compared to the relatively softer and less durable bare aluminum alloys.

Applications: When to Use Alclad or Bare Aluminum

Alclad aluminum is ideal for aerospace and marine applications due to its corrosion-resistant outer layer, providing durability in harsh environments. Bare aluminum is preferred in structural components and electrical applications where conductivity and lightweight properties are prioritized without the need for added corrosion resistance. Choosing between Alclad and bare aluminum depends on exposure conditions and mechanical requirements of the project.

Cost Analysis: Alclad Aluminum vs Bare Aluminum

Alclad aluminum, featuring a thin layer of pure aluminum over an alloy core, commands higher upfront costs compared to bare aluminum due to its enhanced corrosion resistance and durability. While bare aluminum offers lower initial expenses, its susceptibility to oxidation and wear may lead to increased maintenance and replacement costs over time. Evaluating lifecycle expenses, Alclad aluminum often provides better long-term value despite the premium price.

Weight and Performance Considerations

Alclad aluminum features a lightweight aluminum core bonded with thin layers of pure aluminum, offering enhanced corrosion resistance without significant weight increase compared to bare aluminum. Bare aluminum typically weighs slightly less but lacks the protective surface layers, impacting long-term durability and performance in harsh environments. The minimal added weight of Alclad aluminum provides superior balance between strength, corrosion resistance, and longevity ideal for aerospace and marine applications.

Machining and Fabrication Differences

Alclad aluminum features a high-purity aluminum coating bonded to a stronger aluminum alloy core, enhancing corrosion resistance and surface finish compared to bare aluminum. During machining, Alclad aluminum offers improved tool life and less susceptibility to galling, while bare aluminum tends to require more frequent tool maintenance due to higher material adhesion and surface irregularities. Fabrication processes benefit from Alclad aluminum's protective layer, reducing oxidation risks and enabling finer details, whereas bare aluminum demands more careful handling to prevent surface damage and corrosion.

Surface Finish and Aesthetic Qualities

Alclad aluminum features a smooth, reflective surface finish due to its thin layer of pure aluminum bonded to a strong aluminum alloy core, enhancing corrosion resistance and providing a bright, polished aesthetic. Bare aluminum typically exhibits a matte or slightly dull surface prone to oxidation and surface blemishes, requiring additional treatment or coating for improved appearance. The distinct difference in surface textures makes Alclad aluminum preferable in applications where visual appeal and corrosion protection are critical.

Which Is Better for Aerospace? Alclad Aluminum vs Bare Aluminum

Alclad aluminum is preferred in aerospace for its enhanced corrosion resistance due to the thin pure aluminum coating over an aluminum alloy core, significantly extending the lifespan of aircraft components. Bare aluminum, while lightweight and strong, lacks this protective layer, making it more susceptible to oxidation and environmental damage in harsh aerospace settings. The choice depends on the specific application, but Alclad aluminum generally offers superior durability and safety for aerospace structures.

Alclad Aluminum vs Bare Aluminum Infographic

materialdif.com

materialdif.com