Aluminum foil is a thin sheet of metal often used for cooking, packaging, and insulation due to its excellent heat resistance and barrier properties. Aluminum film, typically thinner and more flexible, is commonly used for specialized packaging, electronics, and decorative applications where lightweight and transparency are important. Understanding the differences in thickness, durability, and application helps determine the best choice for specific industrial or household needs.

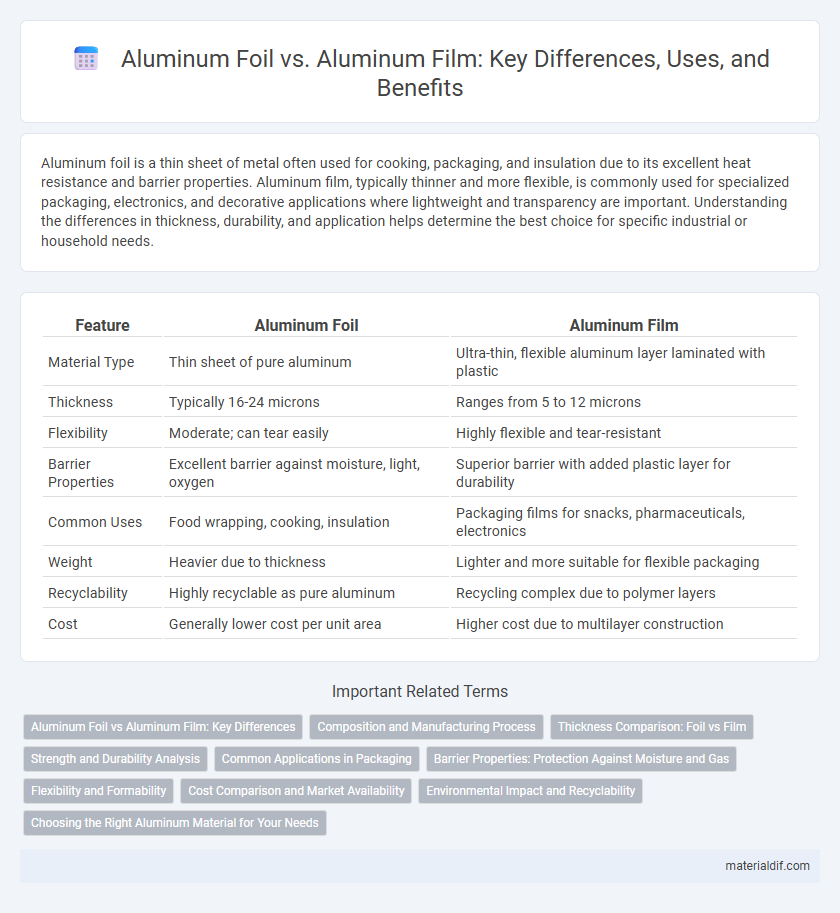

Table of Comparison

| Feature | Aluminum Foil | Aluminum Film |

|---|---|---|

| Material Type | Thin sheet of pure aluminum | Ultra-thin, flexible aluminum layer laminated with plastic |

| Thickness | Typically 16-24 microns | Ranges from 5 to 12 microns |

| Flexibility | Moderate; can tear easily | Highly flexible and tear-resistant |

| Barrier Properties | Excellent barrier against moisture, light, oxygen | Superior barrier with added plastic layer for durability |

| Common Uses | Food wrapping, cooking, insulation | Packaging films for snacks, pharmaceuticals, electronics |

| Weight | Heavier due to thickness | Lighter and more suitable for flexible packaging |

| Recyclability | Highly recyclable as pure aluminum | Recycling complex due to polymer layers |

| Cost | Generally lower cost per unit area | Higher cost due to multilayer construction |

Aluminum Foil vs Aluminum Film: Key Differences

Aluminum foil is a thin, flexible sheet primarily used for packaging, insulation, and cooking, known for its barrier properties against moisture, light, and gases. Aluminum film, often thinner and more delicate, is typically used for specialized applications like electronics and insulation in HVAC systems due to its high reflectivity and lightweight nature. The key differences lie in thickness, flexibility, and typical usage, with foil offering sturdier protection and film providing enhanced reflectivity and lightness.

Composition and Manufacturing Process

Aluminum foil is composed of a pure aluminum sheet rolled into thin layers using a hot and cold rolling process, resulting in a dense, solid structure ideal for packaging and insulation. Aluminum film, by contrast, is typically created by vapor deposition or sputtering thin layers of aluminum onto plastic substrates, combining flexibility with metallic properties for applications like flexible electronics or decorative laminates. The manufacturing of aluminum foil emphasizes mechanical rolling for thickness control, while aluminum film relies on advanced coating techniques to achieve its lightweight and transparent characteristics.

Thickness Comparison: Foil vs Film

Aluminum foil typically ranges from 0.016 mm to 0.2 mm in thickness, providing a durable barrier for packaging and insulation purposes. In contrast, aluminum film is much thinner, usually between 6 microns (0.006 mm) and 50 microns (0.05 mm), offering flexibility and lightness for applications like food wrapping and decorative coatings. The significant thickness difference affects properties such as strength, flexibility, and permeability, making foil suitable for heavy-duty uses and film ideal for lightweight, delicate tasks.

Strength and Durability Analysis

Aluminum foil exhibits higher strength and superior durability compared to aluminum film, making it ideal for heavy-duty packaging and thermal insulation applications. Its thickness and layered structure enhance resistance to tearing, punctures, and moisture penetration. Aluminum film, being thinner and more flexible, offers less mechanical robustness but excels in applications requiring lightweight and conformable barriers.

Common Applications in Packaging

Aluminum foil is widely used for food packaging due to its excellent barrier properties against light, oxygen, and moisture, making it ideal for wrapping perishable items and pharmaceuticals. Aluminum film, typically thinner and more flexible, is preferred for packaging snacks, confectionery, and fresh produce where enhanced printability and sealing capabilities are important. Both materials play crucial roles in maintaining product freshness and extending shelf life in various packaging applications.

Barrier Properties: Protection Against Moisture and Gas

Aluminum foil provides superior barrier properties against moisture, oxygen, and other gases due to its dense, multi-layered metal structure, ensuring excellent protection for food and pharmaceutical packaging. Aluminum film, often a thin aluminum layer deposited on plastic substrates, offers moderate barrier performance but is more flexible and lightweight compared to foil. In applications demanding high moisture and gas resistance, aluminum foil remains the preferred choice for maintaining product freshness and extending shelf life.

Flexibility and Formability

Aluminum foil is highly flexible and can be easily folded, crimped, or molded to fit various shapes, making it ideal for packaging and insulation applications. Aluminum film offers superior formability due to its thinner gauge and uniform thickness, providing enhanced stretchability and conformal coverage for industrial and electronic uses. Both materials excel in flexibility, but aluminum film's finer structure allows for more precise shaping in specialized manufacturing processes.

Cost Comparison and Market Availability

Aluminum foil generally offers a lower cost per square meter compared to aluminum film, making it more economical for bulk packaging applications. Market availability of aluminum foil is broader due to its widespread use in food packaging, insulation, and household products, while aluminum film is more specialized and less commonly stocked. Variations in production methods and raw material usage contribute to cost differences and influence supply chain distribution across global markets.

Environmental Impact and Recyclability

Aluminum foil, commonly used in food packaging, is highly recyclable and can be reprocessed indefinitely without loss of quality, reducing environmental impact when properly recycled. Aluminum film, often combined with plastic layers in multi-material laminates, poses recycling challenges due to difficulty in separating materials, leading to lower recyclability and increased waste. Choosing aluminum foil over aluminum film supports circular economy initiatives by enabling more efficient recycling streams and minimizing landfill contributions.

Choosing the Right Aluminum Material for Your Needs

Aluminum foil offers superior heat resistance and thickness for heavy-duty packaging, making it ideal for cooking, insulation, and wrapping applications. Aluminum film provides greater flexibility and transparency, perfect for light-weight, decorative, or electronic packaging where barrier properties are essential. Selecting the right aluminum material depends on specific requirements such as durability, conductivity, barrier protection, and cost efficiency.

Aluminum Foil vs Aluminum Film Infographic

materialdif.com

materialdif.com