Aluminum billets are semi-finished products produced by extrusion or continuous casting, characterized by a uniform cross-section and tight dimensional tolerances, making them ideal for manufacturing precision components. In contrast, aluminum ingots are larger, cast blocks obtained directly from molten aluminum, primarily serving as raw material for further processing into billets, sheets, or other forms. The choice between aluminum billet and ingot depends on the required mechanical properties, manufacturing process, and final application specifications.

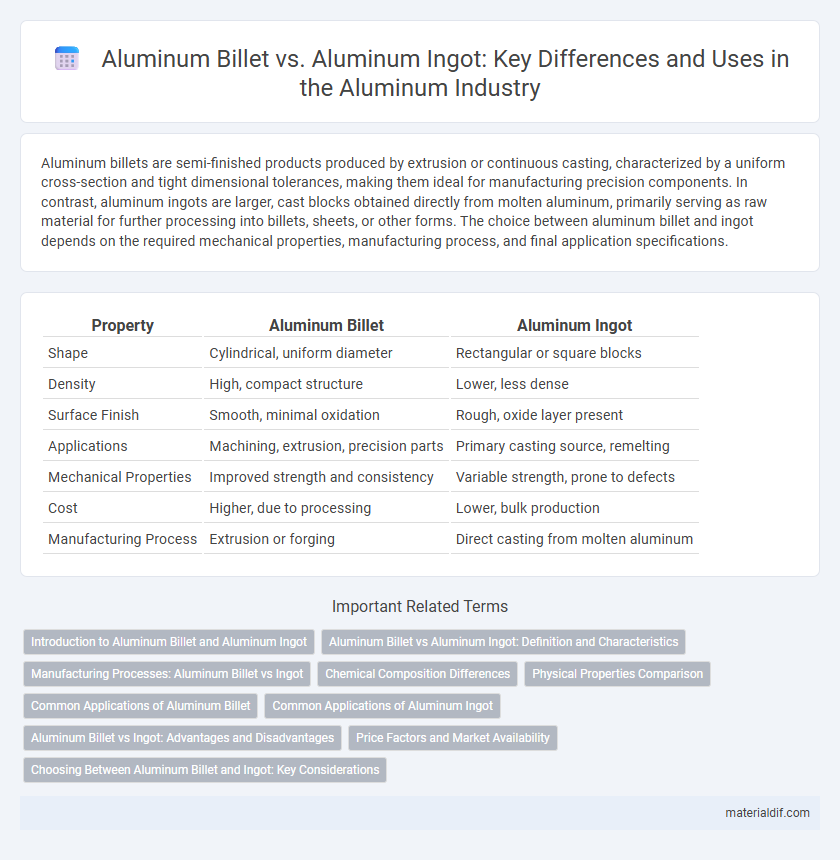

Table of Comparison

| Property | Aluminum Billet | Aluminum Ingot |

|---|---|---|

| Shape | Cylindrical, uniform diameter | Rectangular or square blocks |

| Density | High, compact structure | Lower, less dense |

| Surface Finish | Smooth, minimal oxidation | Rough, oxide layer present |

| Applications | Machining, extrusion, precision parts | Primary casting source, remelting |

| Mechanical Properties | Improved strength and consistency | Variable strength, prone to defects |

| Cost | Higher, due to processing | Lower, bulk production |

| Manufacturing Process | Extrusion or forging | Direct casting from molten aluminum |

Introduction to Aluminum Billet and Aluminum Ingot

Aluminum billets are semi-finished cast products characterized by their uniform grain structure and precise dimensions, commonly used as feedstock for extrusion and forging processes. Aluminum ingots, on the other hand, are large cast blocks or bars formed by solidifying molten aluminum, serving as raw material for further processing into billets or other shapes. The key distinction lies in billets being closely sized and refined for mechanical working, while ingots represent an initial casting stage with more variable dimensions.

Aluminum Billet vs Aluminum Ingot: Definition and Characteristics

Aluminum billets are semi-finished products with a smaller cross-sectional area, typically ranging from 50mm to 250mm, produced through extrusion or continuous casting, offering superior mechanical properties and finer grain structure compared to aluminum ingots. Aluminum ingots are larger, raw cast blocks, usually exceeding 250mm in diameter, serving as primary feedstock for various downstream processes but often containing coarser grains and higher impurity levels. The choice between aluminum billet and ingot depends on desired application, with billets favored for high-precision machined components and ingots preferred for bulk metal processing.

Manufacturing Processes: Aluminum Billet vs Ingot

Aluminum billets are produced through continuous casting or extrusion processes, resulting in a refined microstructure with improved mechanical properties. In contrast, aluminum ingots are typically created via traditional casting methods, leading to larger, coarser grain structures requiring further processing. The manufacturing process of billets offers enhanced dimensional accuracy and surface finish, making them ideal for high-precision applications compared to ingots.

Chemical Composition Differences

Aluminum billets typically have a more controlled and uniform chemical composition compared to aluminum ingots, often containing precise alloying elements tailored for specific mechanical properties and manufacturing processes. Ingots generally exhibit larger chemical composition variability due to casting methods and may contain higher levels of impurities or non-metallic inclusions. This difference influences the suitability of billets for high-performance applications requiring consistent material quality, while ingots are often used as primary stock for further processing.

Physical Properties Comparison

Aluminum billets offer a more uniform grain structure with higher density, resulting in improved mechanical strength and better fatigue resistance compared to aluminum ingots. While aluminum ingots typically have a coarser grain size, leading to lower tensile strength and increased porosity, billets are typically refined through additional processing to enhance thermal conductivity and corrosion resistance. These physical property differences make billets more suitable for precision manufacturing and structural applications requiring consistent performance.

Common Applications of Aluminum Billet

Aluminum billets are widely used in manufacturing automotive components, aerospace parts, and structural applications due to their uniform grain structure and superior mechanical properties. In contrast to aluminum ingots, billets provide better machinability and are often the preferred raw material for precision extrusion processes and CNC machining. Common applications include the production of high-performance engine blocks, aircraft frames, and precision industrial equipment.

Common Applications of Aluminum Ingot

Aluminum ingots are commonly used as raw material in foundries and extrusion plants to produce sheets, plates, and structural components for automotive and aerospace industries. Their purity and standardized shape make them ideal for casting processes, including die casting and sand casting, facilitating the manufacturing of engine parts and machinery. Unlike aluminum billets, ingots are preferred when large-scale melting and alloying are required before further processing.

Aluminum Billet vs Ingot: Advantages and Disadvantages

Aluminum billets offer superior uniformity and higher material quality compared to aluminum ingots, making them ideal for precise machining and structural applications. In contrast, aluminum ingots are more economical for large-scale melting and casting processes but often contain impurities and uneven grain structures that can affect performance. The choice between billets and ingots depends on the specific manufacturing requirements, balancing cost efficiency against mechanical properties and production precision.

Price Factors and Market Availability

Aluminum billets typically command higher prices than aluminum ingots due to their refined quality and precise manufacturing processes, which enhance mechanical properties for specialized applications. Market availability of billets is more limited compared to ingots, as billets are produced in smaller quantities and targeted toward high-performance industries like aerospace and automotive manufacturing. Pricing is also influenced by alloy composition, production volume, and demand fluctuations in key markets such as construction and transportation sectors.

Choosing Between Aluminum Billet and Ingot: Key Considerations

Choosing between aluminum billet and ingot depends on factors such as mechanical properties and intended manufacturing processes. Aluminum billets offer higher density and uniformity, making them ideal for precise machining and high-strength applications, whereas ingots are typically preferred for large-scale extrusion or rolling due to their larger size and lower cost. Assessing requirements for dimensional accuracy, material homogeneity, and production efficiency is essential when selecting the optimal aluminum form.

Aluminum billet vs Aluminum ingot Infographic

materialdif.com

materialdif.com