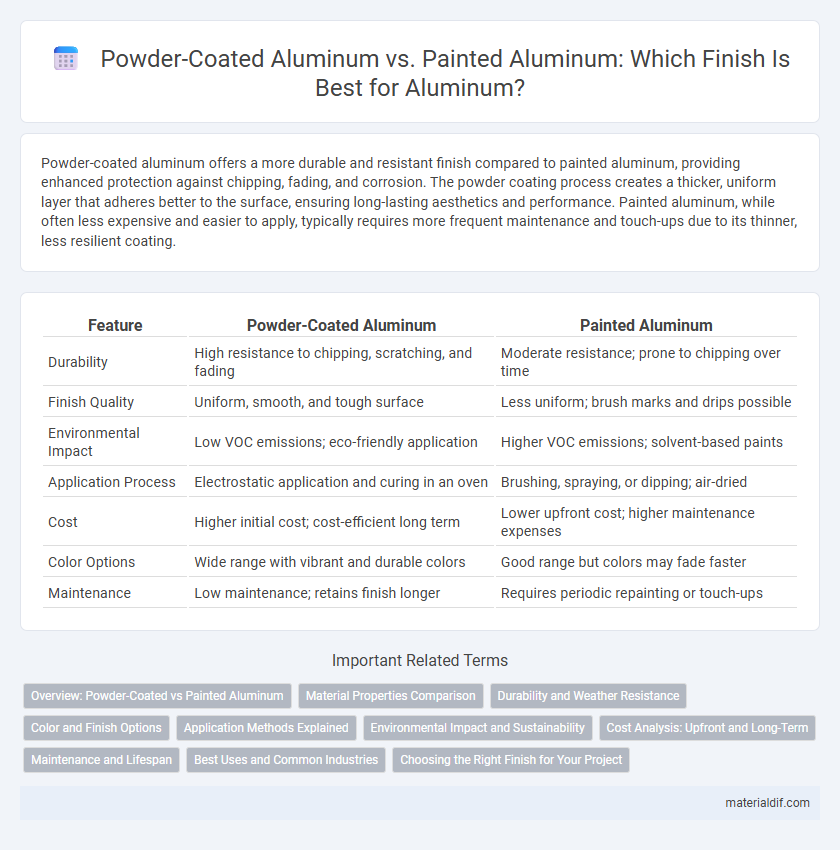

Powder-coated aluminum offers a more durable and resistant finish compared to painted aluminum, providing enhanced protection against chipping, fading, and corrosion. The powder coating process creates a thicker, uniform layer that adheres better to the surface, ensuring long-lasting aesthetics and performance. Painted aluminum, while often less expensive and easier to apply, typically requires more frequent maintenance and touch-ups due to its thinner, less resilient coating.

Table of Comparison

| Feature | Powder-Coated Aluminum | Painted Aluminum |

|---|---|---|

| Durability | High resistance to chipping, scratching, and fading | Moderate resistance; prone to chipping over time |

| Finish Quality | Uniform, smooth, and tough surface | Less uniform; brush marks and drips possible |

| Environmental Impact | Low VOC emissions; eco-friendly application | Higher VOC emissions; solvent-based paints |

| Application Process | Electrostatic application and curing in an oven | Brushing, spraying, or dipping; air-dried |

| Cost | Higher initial cost; cost-efficient long term | Lower upfront cost; higher maintenance expenses |

| Color Options | Wide range with vibrant and durable colors | Good range but colors may fade faster |

| Maintenance | Low maintenance; retains finish longer | Requires periodic repainting or touch-ups |

Overview: Powder-Coated vs Painted Aluminum

Powder-coated aluminum provides a durable, uniform finish by applying dry powder and curing it under heat, resulting in superior corrosion resistance and impact strength compared to painted aluminum. Painted aluminum involves liquid paint application, which can offer greater color variety but is more prone to chipping, fading, and requires frequent maintenance. Choosing between powder-coated and painted aluminum depends on desired aesthetics, environmental exposure, and long-term durability requirements.

Material Properties Comparison

Powder-coated aluminum features a thicker, more durable finish that enhances corrosion resistance and impact strength compared to painted aluminum, which tends to wear and chip more easily. The powder coating process ensures a uniform, UV-resistant layer that prevents fading and maintains color vibrancy over time, unlike conventional paint that can degrade under prolonged sunlight exposure. Both materials offer lightweight and corrosion-resistant properties inherent to aluminum, but powder-coated aluminum provides superior longevity and maintenance benefits.

Durability and Weather Resistance

Powder-coated aluminum offers superior durability and enhanced weather resistance compared to painted aluminum, thanks to its thicker, more uniform protective layer that resists chipping, fading, and corrosion. The electrostatically applied powder coating undergoes curing at high temperatures, creating a robust barrier against UV rays, moisture, and abrasion. Painted aluminum, while aesthetically versatile, typically requires more frequent maintenance due to its thinner paint film that is more prone to cracking and peeling under harsh environmental conditions.

Color and Finish Options

Powder-coated aluminum offers a thicker, more durable finish with a wide range of vibrant colors and textures that resist chipping, fading, and scratching better than traditional painted aluminum. Painted aluminum provides a smoother, glossy finish but is more prone to wear and requires more frequent maintenance to retain its color integrity. Both methods enable customization, though powder coating delivers superior long-term color retention and finish durability in harsh environments.

Application Methods Explained

Powder-coated aluminum involves a dry powder applied electrostatically and cured under heat, creating a durable, uniform finish ideal for outdoor applications and heavy-use environments. Painted aluminum uses liquid paint applied by brushing, spraying, or dipping, requiring multiple coats and longer drying times, suitable for intricate surfaces and color customization. Powder coating generally offers better resistance to chipping, scratching, and fading, while painted finishes provide more versatility in texture and finish options.

Environmental Impact and Sustainability

Powder-coated aluminum offers a more environmentally friendly alternative to painted aluminum due to its low volatile organic compounds (VOC) emissions and minimal waste production during application. The electrostatic application process of powder coating enhances material efficiency, reducing resource consumption and promoting sustainability. Painted aluminum often involves solvent-based paints that release higher VOCs, contributing to air pollution and greater environmental impact.

Cost Analysis: Upfront and Long-Term

Powder-coated aluminum typically has a higher upfront cost than painted aluminum due to the specialized application process and durable resin materials used. Long-term, powder coating offers superior resistance to chipping, fading, and corrosion, reducing maintenance and replacement expenses compared to painted aluminum. The total cost of ownership favors powder-coated aluminum for projects requiring enhanced durability and minimal upkeep over time.

Maintenance and Lifespan

Powder-coated aluminum offers superior durability and requires less maintenance compared to painted aluminum due to its thicker, more resilient finish that resists chipping, fading, and corrosion. Painted aluminum typically demands more frequent touch-ups to address peeling or cracking caused by environmental exposure. The lifespan of powder-coated aluminum generally extends beyond 15 years, whereas painted aluminum surfaces often need recoating within 5 to 10 years to maintain appearance and protection.

Best Uses and Common Industries

Powder-coated aluminum offers superior durability and corrosion resistance, making it ideal for outdoor applications such as architectural facades, automotive parts, and marine equipment. Painted aluminum is often preferred for interior uses where intricate designs and a smoother finish are required, commonly found in consumer electronics, household appliances, and decorative panels. Key industries utilizing powder-coated aluminum include construction, transportation, and aerospace, while painted aluminum is prevalent in consumer goods, signage, and interior design sectors.

Choosing the Right Finish for Your Project

Powder-coated aluminum offers superior durability and resistance to chipping, fading, and corrosion compared to traditional painted aluminum, making it ideal for outdoor and high-traffic applications. Painted aluminum provides a smoother, more customizable finish with a wider range of colors and gloss levels, often preferred for decorative projects requiring precise aesthetic control. Selecting the right finish depends on the environmental exposure, desired longevity, and specific color requirements of your project.

Powder-Coated Aluminum vs Painted Aluminum Infographic

materialdif.com

materialdif.com