Hardcoat anodizing creates a thicker, more durable oxide layer on aluminum, significantly enhancing wear resistance and corrosion protection compared to standard anodizing. Standard anodizing provides aesthetic finishes and moderate protection but lacks the hardness and abrasion resistance essential for heavy-duty applications. Selecting hardcoat anodizing is ideal for components exposed to harsh environments where longevity and surface toughness are critical.

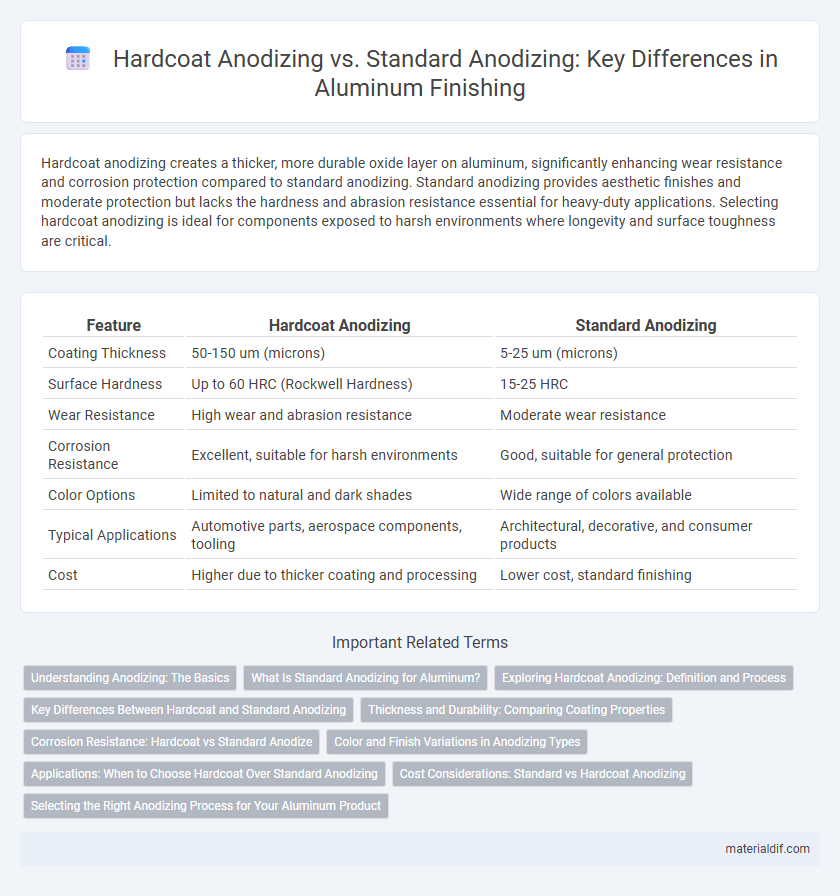

Table of Comparison

| Feature | Hardcoat Anodizing | Standard Anodizing |

|---|---|---|

| Coating Thickness | 50-150 um (microns) | 5-25 um (microns) |

| Surface Hardness | Up to 60 HRC (Rockwell Hardness) | 15-25 HRC |

| Wear Resistance | High wear and abrasion resistance | Moderate wear resistance |

| Corrosion Resistance | Excellent, suitable for harsh environments | Good, suitable for general protection |

| Color Options | Limited to natural and dark shades | Wide range of colors available |

| Typical Applications | Automotive parts, aerospace components, tooling | Architectural, decorative, and consumer products |

| Cost | Higher due to thicker coating and processing | Lower cost, standard finishing |

Understanding Anodizing: The Basics

Hardcoat anodizing, also known as Type II anodizing, creates a thicker and denser oxide layer on aluminum surfaces, enhancing wear resistance and corrosion protection compared to standard anodizing. Standard anodizing typically produces a thinner, more decorative oxide layer, primarily improving surface aesthetics and basic corrosion resistance. Both processes involve electrolytic oxidation, but hardcoat anodizing requires lower temperatures and higher current densities to achieve its superior durability characteristics.

What Is Standard Anodizing for Aluminum?

Standard anodizing for aluminum is an electrochemical process that creates a thin oxide layer on the metal surface, enhancing corrosion resistance and improving surface hardness. This oxide layer, typically ranging from 5 to 25 microns in thickness, is porous, allowing for dyeing and sealing to achieve various colors and finishes. Standard anodizing is commonly used in architectural applications, consumer electronics, and automotive parts due to its durability and aesthetic appeal.

Exploring Hardcoat Anodizing: Definition and Process

Hardcoat anodizing, also known as Type III anodizing, is an electrochemical process that forms a thick, dense, and wear-resistant oxide layer on aluminum surfaces, typically ranging from 25 to 150 microns in thickness. This process involves submerging aluminum parts in a sulfuric acid electrolyte bath cooled to 0-5degC, with high current density to achieve enhanced hardness and corrosion resistance compared to standard anodizing (Type II), which produces thinner oxide layers around 5-25 microns. Hardcoat anodized finishes are ideal for applications requiring extreme durability, such as aerospace, automotive, and industrial machinery components.

Key Differences Between Hardcoat and Standard Anodizing

Hardcoat anodizing produces a thicker, denser oxide layer on aluminum, significantly improving wear resistance and surface hardness compared to standard anodizing. Standard anodizing offers effective corrosion protection and enhanced aesthetic appearance with thinner oxide layers, suitable for decorative applications. The key differences lie in durability and functionality, with hardcoat preferred for industrial uses requiring superior abrasion resistance.

Thickness and Durability: Comparing Coating Properties

Hardcoat anodizing produces a significantly thicker oxide layer, typically ranging from 25 to 150 microns, compared to the 5 to 25 microns found in standard anodizing. This greater thickness enhances surface hardness and wear resistance, making hardcoat anodizing ideal for applications requiring superior durability and corrosion protection. Standard anodizing offers adequate protection for decorative purposes and light-duty environments but lacks the robustness of hardcoat coatings under harsh conditions.

Corrosion Resistance: Hardcoat vs Standard Anodize

Hardcoat anodizing creates a thicker, denser oxide layer on aluminum surfaces, significantly increasing corrosion resistance compared to standard anodizing, which forms a thinner protective film. The enhanced hardness and reduced porosity of hardcoat anodized aluminum improve its durability and resistance to harsh environmental conditions, including saltwater exposure and chemical corrosion. Standard anodizing offers moderate protection suitable for less demanding applications, whereas hardcoat anodizing is ideal for components requiring superior wear and corrosion resistance.

Color and Finish Variations in Anodizing Types

Hardcoat anodizing produces a thicker, more durable oxide layer with a darker, matte finish ideal for high-wear applications, while standard anodizing offers a wider range of color options including vibrant and translucent finishes due to its thinner oxide layer. The color stability of hardcoat anodizing is superior under harsh environmental conditions, maintaining its appearance without fading, unlike standard anodizing which may exhibit color variations over time. Finish variations between the two types are significant, with hardcoat anodizing offering increased abrasion resistance and reduced reflectivity compared to the more decorative and variety-rich finishes of standard anodizing.

Applications: When to Choose Hardcoat Over Standard Anodizing

Hardcoat anodizing is preferred over standard anodizing in applications requiring enhanced wear resistance, higher corrosion protection, and greater surface hardness, such as aerospace components, military equipment, and industrial machinery. Standard anodizing suits decorative purposes and moderate corrosion resistance needs found in consumer electronics and architectural elements. Selecting hardcoat anodizing ensures superior durability in high-friction and harsh environmental conditions where standard anodizing may fall short.

Cost Considerations: Standard vs Hardcoat Anodizing

Standard anodizing typically incurs lower costs due to shorter processing times and less energy consumption compared to hardcoat anodizing. Hardcoat anodizing demands higher voltage and extended treatment durations, significantly increasing operational expenses. The decision between the two often hinges on budget constraints balanced against the need for enhanced surface hardness and corrosion resistance.

Selecting the Right Anodizing Process for Your Aluminum Product

Hardcoat anodizing creates a thicker, more durable oxide layer on aluminum, offering superior wear and corrosion resistance compared to standard anodizing, which produces a thinner, decorative finish. Selecting the right anodizing process depends on the product's application, with hardcoat anodizing ideal for industrial parts exposed to abrasion and harsh environments, while standard anodizing suits architectural and consumer goods requiring aesthetic enhancement. Evaluating factors like environmental conditions, mechanical stress, and desired appearance ensures optimal performance and longevity of the aluminum product.

Hardcoat Anodizing vs Standard Anodizing Infographic

materialdif.com

materialdif.com