Aluminum mesh offers superior ventilation and lightweight properties, making it ideal for applications requiring airflow and filtration. Aluminum perforated sheets provide enhanced structural strength and customizable hole patterns, suited for decorative facades and noise reduction panels. Choosing between aluminum mesh and perforated sheets depends on the specific balance of durability, weight, and aesthetic requirements in your project.

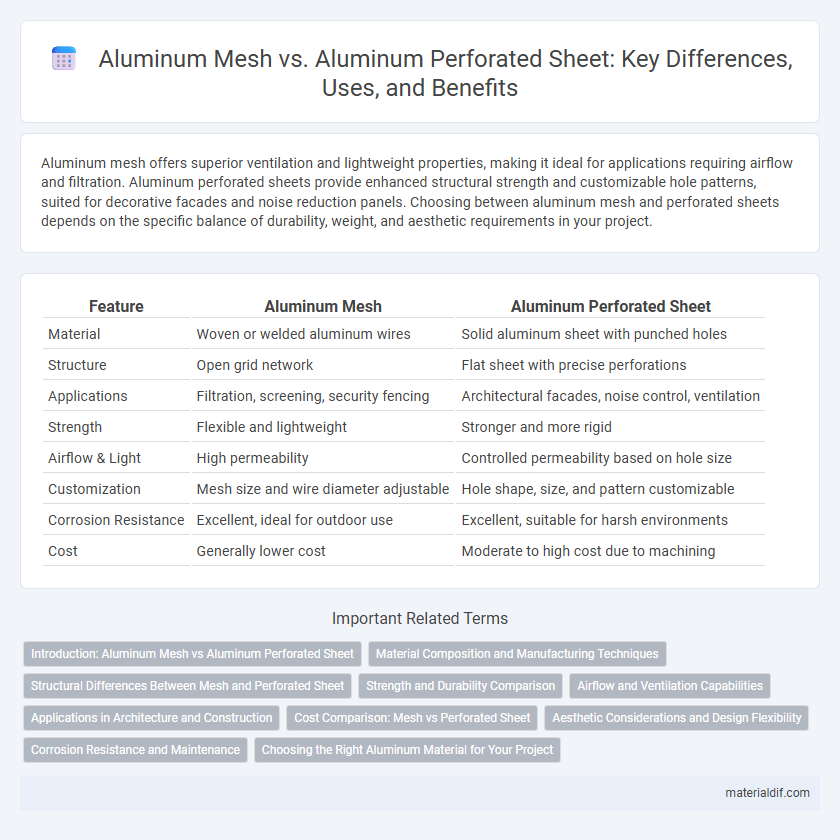

Table of Comparison

| Feature | Aluminum Mesh | Aluminum Perforated Sheet |

|---|---|---|

| Material | Woven or welded aluminum wires | Solid aluminum sheet with punched holes |

| Structure | Open grid network | Flat sheet with precise perforations |

| Applications | Filtration, screening, security fencing | Architectural facades, noise control, ventilation |

| Strength | Flexible and lightweight | Stronger and more rigid |

| Airflow & Light | High permeability | Controlled permeability based on hole size |

| Customization | Mesh size and wire diameter adjustable | Hole shape, size, and pattern customizable |

| Corrosion Resistance | Excellent, ideal for outdoor use | Excellent, suitable for harsh environments |

| Cost | Generally lower cost | Moderate to high cost due to machining |

Introduction: Aluminum Mesh vs Aluminum Perforated Sheet

Aluminum mesh consists of interwoven or welded strands forming a grid pattern, ideal for filtration, screening, and protective applications. Aluminum perforated sheets feature systematically punched holes in various shapes and sizes, providing ventilation, sound absorption, and decorative uses. Both materials offer lightweight, corrosion-resistant solutions but differ in structure and typical industrial applications.

Material Composition and Manufacturing Techniques

Aluminum mesh consists of woven or welded strands of aluminum wire, offering flexibility and open-area patterns ideal for filtration and screening applications. Aluminum perforated sheets are produced by punching precise holes into aluminum plates, providing uniform hole sizes and enhanced structural strength suitable for architectural and industrial uses. Both materials leverage aluminum's corrosion resistance and lightweight properties, but differ significantly in their compositions and manufacturing processes, impacting durability and application specificity.

Structural Differences Between Mesh and Perforated Sheet

Aluminum mesh consists of woven or welded strands creating an open-grid pattern allowing higher airflow and flexibility, while aluminum perforated sheet features uniformly punched holes on a solid sheet providing greater structural strength and rigidity. The mesh's interconnected strands deliver tensile strength and adaptability, contrasting with the perforated sheet's continuous surface that resists bending and offers more load-bearing capacity. These structural differences determine their applications in filtration, screening, and architectural design where airflow or durability is prioritized.

Strength and Durability Comparison

Aluminum mesh offers excellent flexibility and lightweight properties, making it ideal for applications requiring ventilation and filtration, but it generally has lower tensile strength compared to aluminum perforated sheets. Aluminum perforated sheets provide superior strength and durability due to their solid structure with precise holes, making them better suited for heavy-duty applications such as protective barriers and architectural cladding. Corrosion resistance is high in both materials, though perforated sheets often withstand mechanical stresses and impact more effectively over prolonged use.

Airflow and Ventilation Capabilities

Aluminum mesh offers superior airflow and ventilation capabilities due to its open-grid design, allowing maximum air passage while maintaining structural strength. In contrast, aluminum perforated sheets feature a series of punched holes that provide controlled ventilation but restrict airflow compared to mesh. Both materials resist corrosion and are lightweight, making them ideal for applications requiring air circulation and durability.

Applications in Architecture and Construction

Aluminum mesh offers superior ventilation and light filtration, making it ideal for facade cladding, sunshades, and security screens in architectural designs. Aluminum perforated sheets provide enhanced structural strength and aesthetic versatility, commonly used for interior partitions, ceilings, and decorative panels in construction projects. Both materials contribute to sustainable building practices by allowing airflow and natural light while maintaining durability and corrosion resistance.

Cost Comparison: Mesh vs Perforated Sheet

Aluminum mesh generally costs less than aluminum perforated sheets due to its simpler manufacturing process involving woven or welded wire patterns. Perforated sheets require precise punching techniques to create uniform holes, increasing production time and expense. For budget-sensitive projects, aluminum mesh offers a more economical option without compromising durability and corrosion resistance.

Aesthetic Considerations and Design Flexibility

Aluminum mesh offers a lightweight and translucent aesthetic that enhances modern architectural designs by allowing light and air to pass through, creating dynamic visual effects. Aluminum perforated sheets provide a more solid and customizable appearance with varied hole patterns and sizes, enabling intricate design possibilities and increased structural integrity. Both materials combine durability with versatility, but aluminum perforated sheets generally offer greater flexibility for complex decorative patterns in facades and interior applications.

Corrosion Resistance and Maintenance

Aluminum mesh offers superior corrosion resistance due to its high-quality alloy composition and natural oxide layer, making it ideal for outdoor applications with minimal maintenance. In contrast, aluminum perforated sheets, while also corrosion-resistant, may require additional protective treatments or coatings in harsh environments to prevent surface degradation. Regular cleaning and inspection are essential for both materials to maintain their structural integrity and prolong their lifespan in corrosive settings.

Choosing the Right Aluminum Material for Your Project

Aluminum mesh offers excellent ventilation and lightweight properties, making it ideal for applications such as insect screens, filtration, and decorative facades. Aluminum perforated sheets provide superior strength and durability with customizable hole patterns, perfect for architectural cladding, soundproofing, and industrial screening. Selecting the right material depends on project requirements for airflow, structural support, and aesthetic appeal to ensure optimal performance and longevity.

Aluminum Mesh vs Aluminum Perforated Sheet Infographic

materialdif.com

materialdif.com