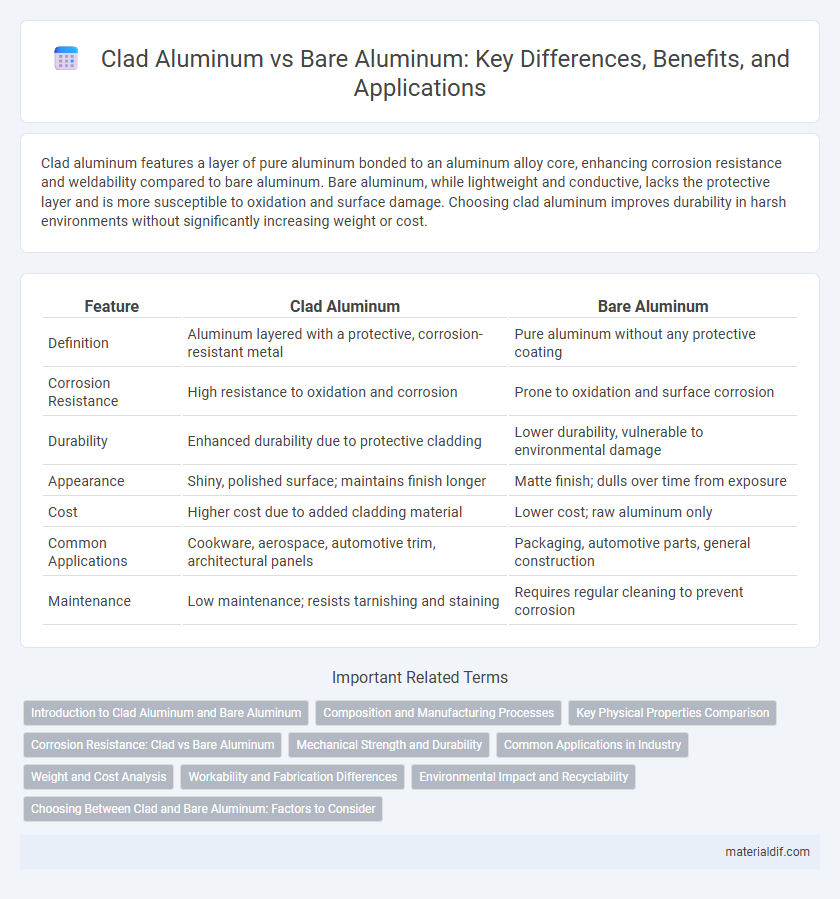

Clad aluminum features a layer of pure aluminum bonded to an aluminum alloy core, enhancing corrosion resistance and weldability compared to bare aluminum. Bare aluminum, while lightweight and conductive, lacks the protective layer and is more susceptible to oxidation and surface damage. Choosing clad aluminum improves durability in harsh environments without significantly increasing weight or cost.

Table of Comparison

| Feature | Clad Aluminum | Bare Aluminum |

|---|---|---|

| Definition | Aluminum layered with a protective, corrosion-resistant metal | Pure aluminum without any protective coating |

| Corrosion Resistance | High resistance to oxidation and corrosion | Prone to oxidation and surface corrosion |

| Durability | Enhanced durability due to protective cladding | Lower durability, vulnerable to environmental damage |

| Appearance | Shiny, polished surface; maintains finish longer | Matte finish; dulls over time from exposure |

| Cost | Higher cost due to added cladding material | Lower cost; raw aluminum only |

| Common Applications | Cookware, aerospace, automotive trim, architectural panels | Packaging, automotive parts, general construction |

| Maintenance | Low maintenance; resists tarnishing and staining | Requires regular cleaning to prevent corrosion |

Introduction to Clad Aluminum and Bare Aluminum

Clad aluminum consists of a core aluminum alloy bonded with a thin layer of pure aluminum, enhancing corrosion resistance and weldability without compromising strength. Bare aluminum refers to untreated aluminum alloys, offering high strength but lower corrosion resistance in harsh environments. The cladding process improves durability, making clad aluminum ideal for marine, aerospace, and chemical applications where exposure to corrosive elements is significant.

Composition and Manufacturing Processes

Clad aluminum features a core aluminum alloy bonded with a thin layer of high-purity aluminum, enhancing corrosion resistance without compromising strength. Bare aluminum consists solely of a single aluminum alloy, typically offering higher strength but lower corrosion resistance compared to clad variants. Manufacturing clad aluminum involves a process called roll bonding, where layers are heated and pressed together, while bare aluminum is produced through standard casting or extrusion methods.

Key Physical Properties Comparison

Clad aluminum features an outer layer of pure aluminum bonded to a core alloy, enhancing corrosion resistance and improving surface conductivity compared to bare aluminum. Bare aluminum, typically an alloy, provides higher strength and better mechanical properties but lacks the protective surface layer that reduces oxidation and discoloration. The density, thermal conductivity, and tensile strength of clad aluminum vary depending on the core alloy composition, typically balancing durability with enhanced surface performance.

Corrosion Resistance: Clad vs Bare Aluminum

Clad aluminum features a thin, pure aluminum layer bonded to an aluminum alloy core, providing superior corrosion resistance compared to bare aluminum by forming a protective oxide barrier that inhibits oxidation and pitting. Bare aluminum, lacking this protective cladding, is more susceptible to environmental factors such as moisture, salt, and acidic conditions that accelerate corrosion and surface degradation. Industries requiring enhanced durability, like aerospace and marine applications, often prefer clad aluminum for its extended lifespan and resistance to corrosion-related failures.

Mechanical Strength and Durability

Clad aluminum features a corrosion-resistant outer layer bonded to high-strength core aluminum, enhancing mechanical strength and extending durability compared to bare aluminum. This combination improves resistance to wear, environmental factors, and fatigue, making clad aluminum ideal for structural applications. Bare aluminum, while lightweight and flexible, lacks the protective cladding, resulting in lower durability and susceptibility to mechanical damage over time.

Common Applications in Industry

Clad aluminum, with its corrosion-resistant outer layer, is commonly utilized in aerospace, automotive, and architectural applications where durability and appearance are critical. Bare aluminum is preferred in electrical components, packaging, and heat exchangers due to its excellent conductivity and lightweight properties. Both forms serve distinct industrial functions by balancing cost, performance, and environmental resistance.

Weight and Cost Analysis

Clad aluminum combines a core of lightweight aluminum with a surface layer of corrosion-resistant alloy, resulting in a higher overall weight compared to bare aluminum but significantly enhanced durability. Bare aluminum offers a lighter option and lower initial cost, yet it lacks the protective properties that clad aluminum provides, often leading to higher maintenance expenses over time. Cost analysis reveals that while clad aluminum has a premium price, its extended lifespan and reduced upkeep make it a cost-effective choice for applications requiring corrosion resistance.

Workability and Fabrication Differences

Clad aluminum features a pure aluminum outer layer bonded to a stronger aluminum alloy core, enhancing corrosion resistance and surface workability compared to bare aluminum. Bare aluminum alloys typically offer better strength but are prone to surface oxidation and require more protective finishing during fabrication. The bonded cladding improves machinability and weldability, making it preferable for applications demanding superior surface quality and ease of forming.

Environmental Impact and Recyclability

Clad aluminum offers enhanced corrosion resistance, reducing the need for frequent replacements and minimizing environmental waste compared to bare aluminum. The recyclability of clad aluminum is slightly more complex due to the layered materials but remains efficient, preserving energy and reducing landfill contributions. Bare aluminum, while easier to recycle in a pure form, lacks the protective coating that extends product lifespan, potentially increasing overall environmental impact through higher material consumption.

Choosing Between Clad and Bare Aluminum: Factors to Consider

Choosing between clad aluminum and bare aluminum depends on factors such as corrosion resistance, strength requirements, and cost efficiency. Clad aluminum offers enhanced protection against oxidation and weathering, making it ideal for applications exposed to harsh environments, while bare aluminum is favored for lightweight and lower-cost projects where surface protection is less critical. Consider the specific environmental conditions, mechanical demands, and budget constraints to determine the optimal aluminum type for your application.

Clad aluminum vs Bare aluminum Infographic

materialdif.com

materialdif.com