Hot working aluminum PET involves shaping the material at elevated temperatures, allowing for easier deformation and reduced risk of cracking, which improves ductility and grain refinement. Cold working, performed at or near room temperature, increases strength and hardness through strain hardening but reduces ductility and may require subsequent annealing to restore flexibility. Choosing between hot and cold working depends on the desired mechanical properties and final application requirements of the aluminum PET component.

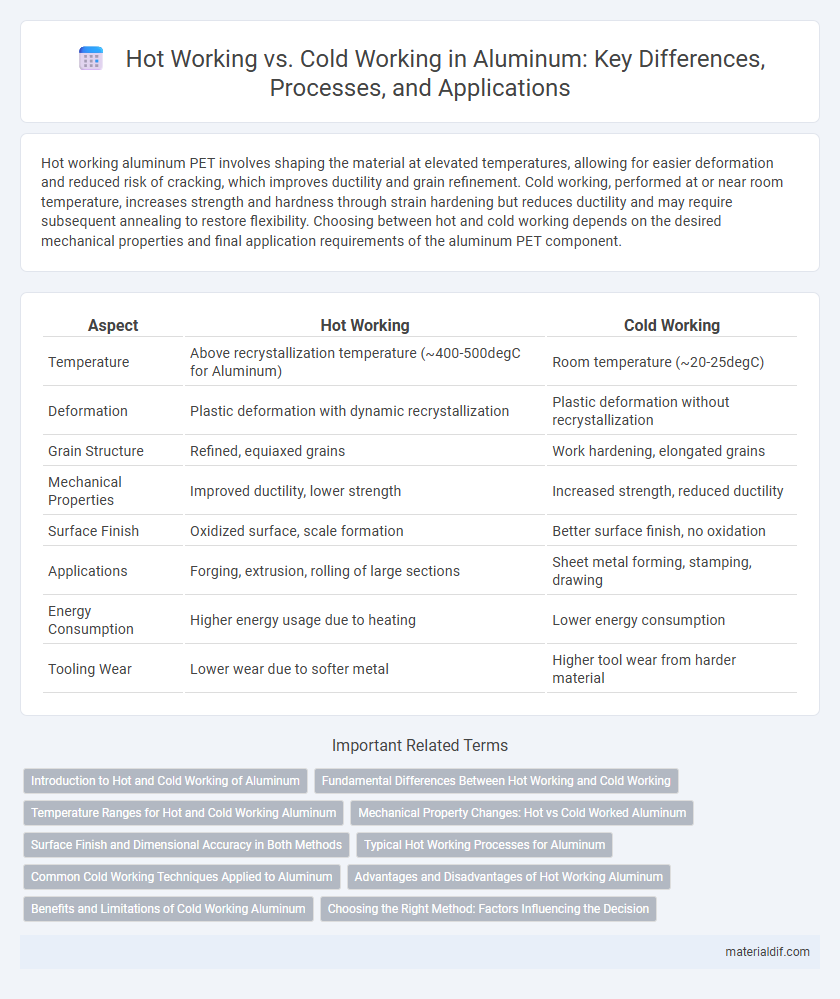

Table of Comparison

| Aspect | Hot Working | Cold Working |

|---|---|---|

| Temperature | Above recrystallization temperature (~400-500degC for Aluminum) | Room temperature (~20-25degC) |

| Deformation | Plastic deformation with dynamic recrystallization | Plastic deformation without recrystallization |

| Grain Structure | Refined, equiaxed grains | Work hardening, elongated grains |

| Mechanical Properties | Improved ductility, lower strength | Increased strength, reduced ductility |

| Surface Finish | Oxidized surface, scale formation | Better surface finish, no oxidation |

| Applications | Forging, extrusion, rolling of large sections | Sheet metal forming, stamping, drawing |

| Energy Consumption | Higher energy usage due to heating | Lower energy consumption |

| Tooling Wear | Lower wear due to softer metal | Higher tool wear from harder material |

Introduction to Hot and Cold Working of Aluminum

Hot working of aluminum involves deforming the metal at temperatures above its recrystallization point, typically above 300degC, which enhances ductility and reduces work hardening. Cold working, performed below room temperature, increases strength and hardness through strain hardening but requires more force and results in reduced ductility. Understanding the differences between hot and cold working processes is crucial for optimizing aluminum's mechanical properties and surface finish in manufacturing.

Fundamental Differences Between Hot Working and Cold Working

Hot working of aluminum involves deforming the metal above its recrystallization temperature, enabling easier shaping and reduced risk of strain hardening, while cold working occurs below this temperature, increasing strength through strain hardening but reducing ductility. Hot working processes like forging and extrusion promote grain refinement and improved toughness, whereas cold working methods such as rolling and drawing enhance surface finish and dimensional accuracy. The fundamental difference lies in temperature control, affecting aluminum's mechanical properties, microstructure, and subsequent heat treatment requirements.

Temperature Ranges for Hot and Cold Working Aluminum

Hot working aluminum typically involves temperatures between 350degC to 500degC, enabling plastic deformation with reduced risk of cracking and improved ductility. Cold working occurs below 150degC, often near room temperature, where aluminum undergoes strain hardening but requires greater force and may introduce residual stresses. Understanding these temperature ranges is critical for optimizing aluminum's mechanical properties and manufacturing processes.

Mechanical Property Changes: Hot vs Cold Worked Aluminum

Hot working aluminum at temperatures above its recrystallization point enhances ductility and decreases hardness by refining grain structure and relieving internal stresses. Cold working aluminum below recrystallization temperature increases strength and hardness through strain hardening but reduces ductility due to the accumulation of dislocations. Mechanical properties such as tensile strength and yield strength are higher in cold-worked aluminum, while hot-worked aluminum offers improved formability for complex shapes.

Surface Finish and Dimensional Accuracy in Both Methods

Hot working aluminum involves deforming the metal above its recrystallization temperature, resulting in a rougher surface finish due to oxidation and scale formation, while enabling easier shaping with less force. Cold working aluminum, performed below recrystallization temperature, produces smoother surface finishes and tighter dimensional accuracy, but increases hardness and residual stresses that may require annealing. Dimensional control in cold working is superior, making it ideal for precision components, whereas hot working offers better workability for complex shapes despite less precise tolerances.

Typical Hot Working Processes for Aluminum

Typical hot working processes for aluminum include hot rolling, extrusion, forging, and hot pressing, which are performed above the metal's recrystallization temperature to enhance ductility and reduce internal stresses. These methods allow aluminum to be shaped more easily while improving mechanical properties such as strength and grain refinement. Controlled temperature and strain rates during hot working are crucial to prevent surface defects and optimize microstructural evolution.

Common Cold Working Techniques Applied to Aluminum

Common cold working techniques applied to aluminum include rolling, drawing, and pressing, which enhance the metal's strength and surface finish without altering its chemical composition. These processes typically increase aluminum's hardness and tensile strength through strain hardening while maintaining dimensional accuracy. Cold working is preferred for producing thin sheets, wires, and intricate shapes requiring tight tolerances and improved mechanical properties.

Advantages and Disadvantages of Hot Working Aluminum

Hot working aluminum allows for significant deformation without cracking due to increased ductility above its recrystallization temperature, enhancing formability and reducing residual stresses. This process improves grain refinement and mechanical properties but can lead to oxidation and surface scale formation, requiring subsequent surface treatment. While hot working enables complex shapes and large reductions, it generally results in lower dimensional accuracy and surface finish compared to cold working.

Benefits and Limitations of Cold Working Aluminum

Cold working aluminum enhances its strength and hardness through strain hardening, improving wear resistance and dimensional accuracy for precision applications. However, this process reduces ductility, increasing the risk of cracking and limiting formability for complex shapes. Cold working also induces residual stresses that may require subsequent annealing to restore material ductility and relieve stress.

Choosing the Right Method: Factors Influencing the Decision

Selecting the appropriate working method for aluminum depends on factors such as desired mechanical properties, dimensional accuracy, and production volume. Hot working is preferred for large deformations and improving ductility by operating above recrystallization temperature, while cold working enhances strength and surface finish through strain hardening below that temperature. Considerations like cost, tooling wear, and final product application also influence the decision between hot and cold working processes.

Hot Working vs Cold Working Infographic

materialdif.com

materialdif.com