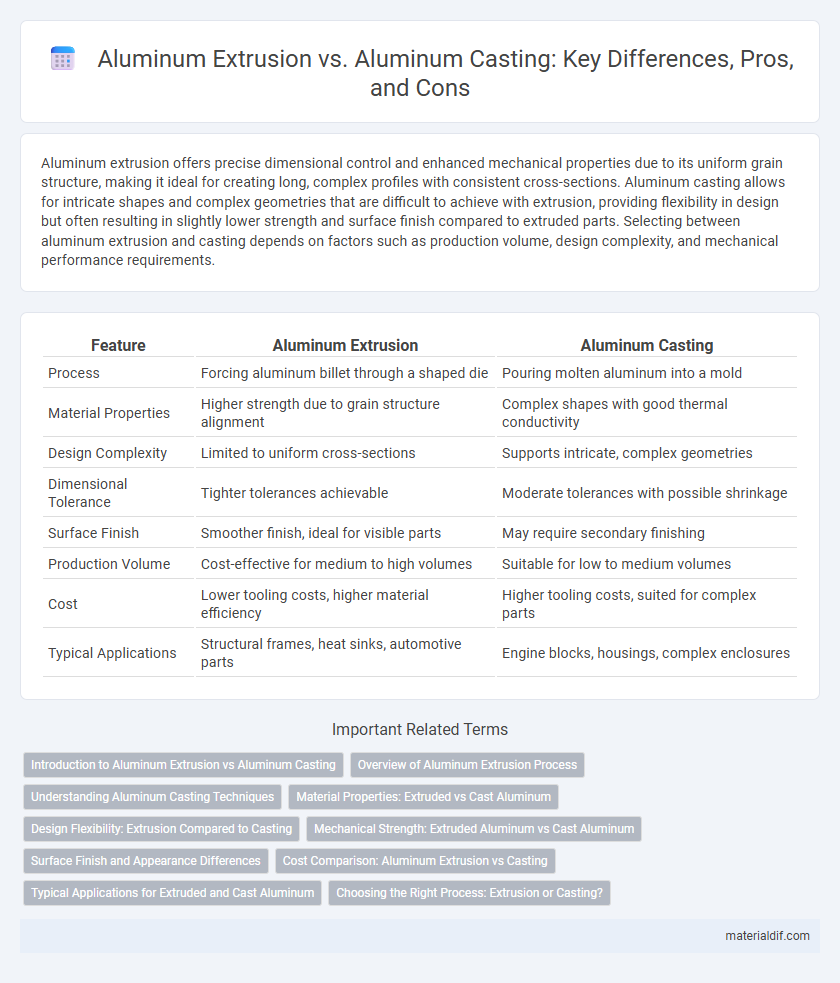

Aluminum extrusion offers precise dimensional control and enhanced mechanical properties due to its uniform grain structure, making it ideal for creating long, complex profiles with consistent cross-sections. Aluminum casting allows for intricate shapes and complex geometries that are difficult to achieve with extrusion, providing flexibility in design but often resulting in slightly lower strength and surface finish compared to extruded parts. Selecting between aluminum extrusion and casting depends on factors such as production volume, design complexity, and mechanical performance requirements.

Table of Comparison

| Feature | Aluminum Extrusion | Aluminum Casting |

|---|---|---|

| Process | Forcing aluminum billet through a shaped die | Pouring molten aluminum into a mold |

| Material Properties | Higher strength due to grain structure alignment | Complex shapes with good thermal conductivity |

| Design Complexity | Limited to uniform cross-sections | Supports intricate, complex geometries |

| Dimensional Tolerance | Tighter tolerances achievable | Moderate tolerances with possible shrinkage |

| Surface Finish | Smoother finish, ideal for visible parts | May require secondary finishing |

| Production Volume | Cost-effective for medium to high volumes | Suitable for low to medium volumes |

| Cost | Lower tooling costs, higher material efficiency | Higher tooling costs, suited for complex parts |

| Typical Applications | Structural frames, heat sinks, automotive parts | Engine blocks, housings, complex enclosures |

Introduction to Aluminum Extrusion vs Aluminum Casting

Aluminum extrusion involves forcing heated aluminum through a shaped die, producing long profiles with consistent cross-sections ideal for structural applications. Aluminum casting shapes molten aluminum poured into molds, enabling complex geometries and intricate details suitable for automotive and aerospace components. Each process offers distinct advantages in terms of strength, weight, and design flexibility depending on the intended use and production volume.

Overview of Aluminum Extrusion Process

Aluminum extrusion involves forcing heated aluminum billets through a die to create long, continuous shapes with uniform cross-sections, offering precise dimensional control and high structural integrity. This process enables the production of complex profiles with excellent surface finish and lightweight properties ideal for aerospace, automotive, and construction industries. Compared to aluminum casting, extrusion provides enhanced mechanical strength due to the metal's grain structure alignment along the extruded profile.

Understanding Aluminum Casting Techniques

Aluminum casting techniques involve pouring molten aluminum into molds to create complex shapes with excellent mechanical properties and fine surface finishes. Common methods include sand casting, die casting, and investment casting, each offering unique benefits like high dimensional accuracy, reduced machining, and suitability for large or intricate parts. These techniques enable production of lightweight, corrosion-resistant components essential for aerospace, automotive, and construction industries.

Material Properties: Extruded vs Cast Aluminum

Extruded aluminum offers superior strength-to-weight ratio and better mechanical properties due to its grain structure, which is aligned along the extrusion direction, enhancing tensile strength and fatigue resistance. Cast aluminum, while more versatile in complex shapes, tends to have more porosity and lower mechanical strength compared to extruded aluminum, often resulting in reduced ductility and impact resistance. The choice between extruded and cast aluminum heavily depends on required structural integrity, with extrusions favored for high-performance applications requiring consistent material properties.

Design Flexibility: Extrusion Compared to Casting

Aluminum extrusion offers superior design flexibility compared to casting by enabling complex cross-sectional profiles with high precision and consistent tolerances. Unlike casting, which is limited by mold constraints and can result in dimensional inaccuracies and porosity, extrusion allows for continuous production of uniform shapes ideal for structural and aesthetic applications. This process supports intricate designs with thinner walls and longer lengths, enhancing both mechanical performance and material efficiency.

Mechanical Strength: Extruded Aluminum vs Cast Aluminum

Extruded aluminum typically offers superior mechanical strength compared to cast aluminum due to its grain structure, which aligns along the length of the extrusion and enhances directional strength. Cast aluminum generally has a more isotropic grain structure but often contains porosity and defects that can reduce its overall mechanical performance. For applications requiring high tensile strength and fatigue resistance, extruded aluminum is usually preferred over cast aluminum.

Surface Finish and Appearance Differences

Aluminum extrusion produces parts with smooth, consistent surfaces and sharp, well-defined edges ideal for aesthetic applications requiring uniformity. In contrast, aluminum casting often results in rougher textures and may require secondary machining or surface treatments to achieve a polished appearance. Surface finish quality from extrusion typically surpasses casting, making it preferable for visible components demanding superior visual appeal.

Cost Comparison: Aluminum Extrusion vs Casting

Aluminum extrusion typically offers lower production costs for high-volume runs due to its efficient process and minimal material waste, making it ideal for creating long, uniform profiles. In contrast, aluminum casting incurs higher initial tooling expenses but becomes cost-effective for complex shapes and low to medium production volumes. Evaluating cost efficiency depends on factors such as design complexity, production volume, and material usage, with extrusion favored for simpler, repetitive profiles and casting preferred for intricate, customized components.

Typical Applications for Extruded and Cast Aluminum

Extruded aluminum is commonly used in construction frameworks, automotive parts, and aerospace components due to its strength, lightweight nature, and design versatility. Cast aluminum is typically found in engine blocks, machinery housings, and complex-shaped tools where intricate details and higher structural integrity are required. Both processes serve crucial roles across industries, with extrusion favoring uniform cross-sections and casting enabling detailed, three-dimensional designs.

Choosing the Right Process: Extrusion or Casting?

Aluminum extrusion offers superior strength-to-weight ratio and tight dimensional tolerances, making it ideal for structural components and complex profiles. Aluminum casting provides greater design flexibility and can produce intricate shapes with internal cavities, suitable for parts requiring complex geometries. Selecting between aluminum extrusion and casting depends on factors such as mechanical requirements, production volume, and cost efficiency.

Aluminum Extrusion vs Aluminum Casting Infographic

materialdif.com

materialdif.com