Anodized aluminum features a durable, corrosion-resistant oxide layer that enhances surface hardness and offers superior protection against scratches and environmental damage compared to non-anodized aluminum. Non-anodized aluminum, though lighter and more malleable, is more prone to oxidation and surface wear, requiring additional coatings or treatments for long-term durability. Choosing anodized aluminum ensures improved aesthetic appeal and longevity specifically suited for harsh or outdoor environments.

Table of Comparison

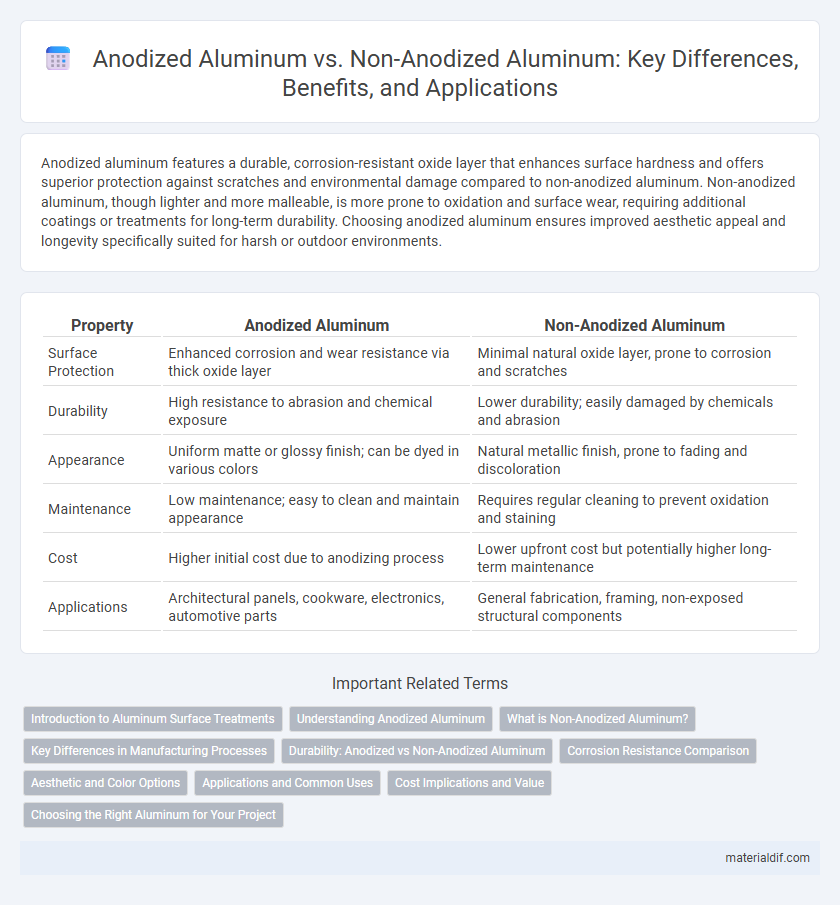

| Property | Anodized Aluminum | Non-Anodized Aluminum |

|---|---|---|

| Surface Protection | Enhanced corrosion and wear resistance via thick oxide layer | Minimal natural oxide layer, prone to corrosion and scratches |

| Durability | High resistance to abrasion and chemical exposure | Lower durability; easily damaged by chemicals and abrasion |

| Appearance | Uniform matte or glossy finish; can be dyed in various colors | Natural metallic finish, prone to fading and discoloration |

| Maintenance | Low maintenance; easy to clean and maintain appearance | Requires regular cleaning to prevent oxidation and staining |

| Cost | Higher initial cost due to anodizing process | Lower upfront cost but potentially higher long-term maintenance |

| Applications | Architectural panels, cookware, electronics, automotive parts | General fabrication, framing, non-exposed structural components |

Introduction to Aluminum Surface Treatments

Anodized aluminum undergoes an electrochemical process that enhances corrosion resistance, surface hardness, and aesthetic appeal by forming a durable oxide layer. Non-anodized aluminum lacks this protective coating, making it more susceptible to oxidation, wear, and environmental damage over time. Surface treatments like anodizing play a crucial role in extending aluminum's lifespan and improving its performance in diverse industrial and architectural applications.

Understanding Anodized Aluminum

Anodized aluminum features a protective oxide layer created through an electrochemical process that enhances corrosion resistance, durability, and surface hardness compared to non-anodized aluminum. This oxide layer also improves paint adhesion and offers better wear and scratch resistance, making anodized aluminum ideal for architectural, automotive, and consumer goods applications. Non-anodized aluminum lacks this hardened surface, making it more susceptible to oxidation, scratches, and environmental damage over time.

What is Non-Anodized Aluminum?

Non-anodized aluminum refers to aluminum in its natural, untreated state without the electrochemical process that creates a protective oxide layer. This form of aluminum is more susceptible to corrosion, scratches, and wear compared to anodized aluminum, which has enhanced durability and a thicker oxide surface layer. Non-anodized aluminum typically requires additional coatings or treatments to improve its resistance to environmental factors and extend its lifespan.

Key Differences in Manufacturing Processes

Anodized aluminum undergoes an electrochemical process that forms a thick, durable oxide layer on its surface, enhancing corrosion resistance and allowing for dyeing and improved wear properties. Non-anodized aluminum retains its natural oxide film, which is thin and less protective, making it more susceptible to corrosion and surface damage. The anodizing manufacturing process involves immersion in an acid electrolyte bath, typically sulfuric acid, where electrical current accelerates oxide layer formation, contrasting with the absence of such treatment in non-anodized aluminum production.

Durability: Anodized vs Non-Anodized Aluminum

Anodized aluminum offers superior durability compared to non-anodized aluminum due to its enhanced corrosion resistance and increased surface hardness, which protects against wear and environmental damage. The anodizing process forms a thick oxide layer that acts as a tough, protective barrier, extending the lifespan of aluminum products in harsh conditions. Non-anodized aluminum lacks this protective coating, making it more susceptible to scratches, oxidation, and degradation over time.

Corrosion Resistance Comparison

Anodized aluminum features a thick, protective oxide layer formed through electrochemical treatment, significantly enhancing its corrosion resistance compared to non-anodized aluminum, which has only a thin natural oxide film prone to wear and environmental damage. This anodic layer also improves durability in harsh environments, resisting oxidation, moisture, and chemical exposure more effectively. Non-anodized aluminum, while lightweight and flexible, requires additional coatings or treatments to achieve comparable protection against corrosion.

Aesthetic and Color Options

Anodized aluminum offers enhanced aesthetic appeal through its vibrant, long-lasting color options, achieved by electrochemical oxidation that creates a durable, corrosion-resistant surface. Non-anodized aluminum typically presents a natural metallic finish that can be polished or painted but lacks the depth and variety of colors available with anodizing. The anodizing process allows for a wide palette of uniform, fade-resistant hues, making it ideal for architectural, automotive, and consumer product applications where visual appearance is critical.

Applications and Common Uses

Anodized aluminum is widely used in aerospace, automotive, and architectural applications due to its enhanced corrosion resistance, durability, and aesthetic finish, making it ideal for exterior panels, heat sinks, and decorative elements. Non-anodized aluminum is commonly employed in electrical wiring, packaging, and construction where cost-effectiveness and lightweight properties are prioritized over surface protection. The choice between anodized and non-anodized aluminum largely depends on the environmental exposure and mechanical demands of the specific application.

Cost Implications and Value

Anodized aluminum typically involves higher upfront costs due to the additional electrochemical treatment that enhances surface durability, corrosion resistance, and aesthetic appeal. Non-anodized aluminum offers a lower initial investment but may lead to increased maintenance expenses and shorter lifespan in harsh environments. The long-term value of anodized aluminum often justifies its premium price by reducing replacement frequency and preserving structural integrity.

Choosing the Right Aluminum for Your Project

Anodized aluminum offers enhanced corrosion resistance, increased surface hardness, and improved aesthetic appeal due to its protective oxide layer, making it ideal for outdoor and high-wear applications. Non-anodized aluminum, while more cost-effective and easier to fabricate, lacks this durable coating and is more susceptible to oxidation and surface damage. Selecting anodized or non-anodized aluminum depends on project requirements like environmental exposure, wear resistance, budget constraints, and desired finish.

Anodized Aluminum vs Non-Anodized Aluminum Infographic

materialdif.com

materialdif.com