Brushed aluminum features a textured, matte finish created by sanding the metal surface, which enhances its resistance to fingerprints and scratches, making it ideal for functional and industrial applications. Polished aluminum undergoes a buffing process that produces a smooth, reflective surface, offering a sleek and shiny appearance suitable for decorative and aesthetic purposes. The choice between brushed and polished aluminum depends on the desired visual effect and maintenance requirements, with brushed aluminum providing a more subdued look and polished aluminum delivering high reflectivity.

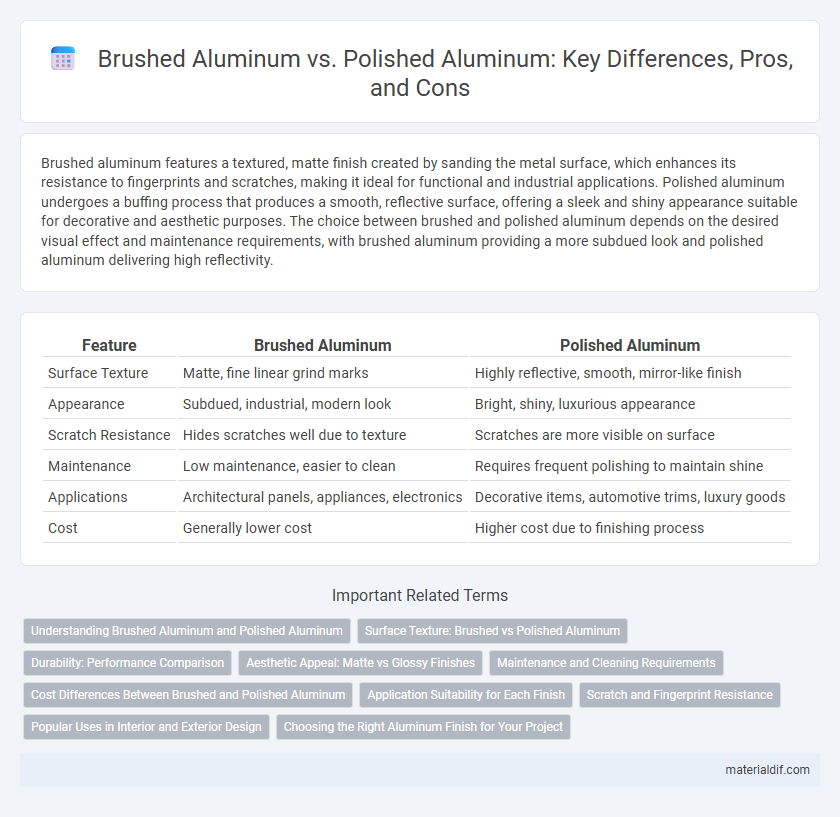

Table of Comparison

| Feature | Brushed Aluminum | Polished Aluminum |

|---|---|---|

| Surface Texture | Matte, fine linear grind marks | Highly reflective, smooth, mirror-like finish |

| Appearance | Subdued, industrial, modern look | Bright, shiny, luxurious appearance |

| Scratch Resistance | Hides scratches well due to texture | Scratches are more visible on surface |

| Maintenance | Low maintenance, easier to clean | Requires frequent polishing to maintain shine |

| Applications | Architectural panels, appliances, electronics | Decorative items, automotive trims, luxury goods |

| Cost | Generally lower cost | Higher cost due to finishing process |

Understanding Brushed Aluminum and Polished Aluminum

Brushed aluminum features a textured, matte finish created by a unidirectional satin brushing process that enhances its resistance to fingerprints and scratches, making it ideal for applications requiring a sleek yet durable surface. Polished aluminum undergoes a mechanical polishing process to achieve a reflective, mirror-like appearance, offering a high-gloss finish that emphasizes aesthetic appeal but requires more maintenance to prevent oxidation and surface imperfections. Understanding these differences is essential for selecting aluminum finishes tailored to specific design and functional requirements in industries such as automotive, architecture, and consumer electronics.

Surface Texture: Brushed vs Polished Aluminum

Brushed aluminum features a matte finish with fine, linear scratches that create a textured, non-reflective surface, enhancing grip and hiding fingerprints. Polished aluminum, in contrast, exhibits a smooth, mirror-like shine due to its highly reflective surface achieved through extensive buffing and polishing processes. The choice between brushed and polished aluminum depends on the desired aesthetic and functional application, with brushed surfaces preferred for durability and low maintenance, while polished surfaces offer a sleek, high-gloss appearance.

Durability: Performance Comparison

Brushed aluminum features a textured surface that enhances its resistance to scratches and fingerprints, making it highly durable in everyday use environments. Polished aluminum, while aesthetically superior with a mirror-like finish, tends to be more prone to surface damage and requires regular maintenance to retain its shine. In terms of performance, brushed aluminum demonstrates greater longevity and withstands wear better, particularly in high-contact applications.

Aesthetic Appeal: Matte vs Glossy Finishes

Brushed aluminum offers a matte finish with a textured surface that reduces glare and hides fingerprints, making it ideal for industrial and contemporary designs. Polished aluminum features a glossy, mirror-like finish that enhances brightness and reflects light, providing a sleek and high-end appearance. Choosing between these finishes depends on the desired aesthetic appeal, with brushed aluminum emphasizing subtle sophistication and polished aluminum showcasing striking elegance.

Maintenance and Cleaning Requirements

Brushed aluminum features a matte finish with fine grooves that effectively hide fingerprints, smudges, and minor scratches, reducing the frequency of cleaning compared to polished aluminum. Polished aluminum's reflective surface demands regular cleaning with non-abrasive cleaners to maintain its shine and prevent oxidation, making it more maintenance-intensive. Both finishes require gentle cleaning agents, but brushed aluminum is often preferred for environments prioritizing low-maintenance durability.

Cost Differences Between Brushed and Polished Aluminum

Brushed aluminum typically costs less than polished aluminum due to its simpler finishing process, which involves abrasive brushing to create a matte texture. Polished aluminum undergoes more labor-intensive buffing and polishing procedures to achieve a mirror-like, reflective surface, increasing production time and expenses. The material and maintenance costs for polished aluminum also contribute to its higher overall price compared to brushed aluminum.

Application Suitability for Each Finish

Brushed aluminum features a textured, matte surface that excels in applications requiring reduced glare and enhanced scratch resistance, making it ideal for consumer electronics, automotive interiors, and architectural panels. Polished aluminum offers a highly reflective, mirror-like finish favored in decorative elements, luxury automotive trim, and high-end signage due to its aesthetic appeal and brightness. The choice between brushed and polished aluminum depends on whether durability and subtlety or visual impact and shine are prioritized in the application.

Scratch and Fingerprint Resistance

Brushed aluminum features a textured surface that significantly reduces the visibility of scratches and fingerprints, making it ideal for high-contact applications. Polished aluminum has a smooth, reflective finish that tends to show scratches and fingerprints more prominently, requiring frequent cleaning to maintain its appearance. The micro-abrasions in brushed aluminum create a matte look, enhancing its durability against everyday wear and smudging.

Popular Uses in Interior and Exterior Design

Brushed aluminum is widely used in interior design for its matte, textured finish that reduces glare and adds a modern, industrial aesthetic to furniture, cabinetry, and appliances. Polished aluminum, known for its reflective, mirror-like surface, is favored in exterior design applications such as decorative facades, architectural accents, and outdoor fixtures where high shine and corrosion resistance enhance visual appeal. Both finishes offer durability and corrosion resistance, making them practical choices for versatile design environments.

Choosing the Right Aluminum Finish for Your Project

Brushed aluminum offers a matte, textured surface that reduces glare and hides fingerprints, making it ideal for industrial designs and functional applications. Polished aluminum provides a sleek, reflective finish that enhances aesthetic appeal, perfect for decorative projects requiring a shiny, mirror-like appearance. Selecting the right aluminum finish depends on the desired balance between durability, maintenance, and visual impact for your specific project.

Brushed Aluminum vs Polished Aluminum Infographic

materialdif.com

materialdif.com