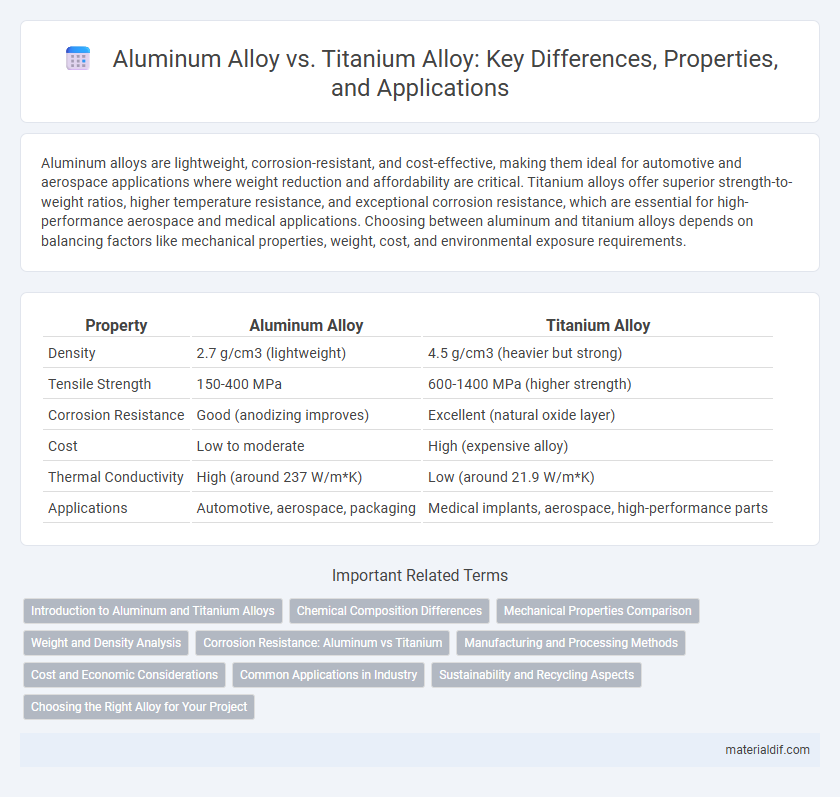

Aluminum alloys are lightweight, corrosion-resistant, and cost-effective, making them ideal for automotive and aerospace applications where weight reduction and affordability are critical. Titanium alloys offer superior strength-to-weight ratios, higher temperature resistance, and exceptional corrosion resistance, which are essential for high-performance aerospace and medical applications. Choosing between aluminum and titanium alloys depends on balancing factors like mechanical properties, weight, cost, and environmental exposure requirements.

Table of Comparison

| Property | Aluminum Alloy | Titanium Alloy |

|---|---|---|

| Density | 2.7 g/cm3 (lightweight) | 4.5 g/cm3 (heavier but strong) |

| Tensile Strength | 150-400 MPa | 600-1400 MPa (higher strength) |

| Corrosion Resistance | Good (anodizing improves) | Excellent (natural oxide layer) |

| Cost | Low to moderate | High (expensive alloy) |

| Thermal Conductivity | High (around 237 W/m*K) | Low (around 21.9 W/m*K) |

| Applications | Automotive, aerospace, packaging | Medical implants, aerospace, high-performance parts |

Introduction to Aluminum and Titanium Alloys

Aluminum alloys are lightweight, corrosion-resistant materials commonly used in aerospace, automotive, and construction industries due to their excellent strength-to-weight ratio and good thermal conductivity. Titanium alloys offer superior strength, exceptional corrosion resistance, and high-temperature performance, making them ideal for aerospace, medical implants, and marine applications. Both aluminum and titanium alloys enhance structural efficiency, but titanium alloys typically provide higher tensile strength and fatigue resistance at a greater cost.

Chemical Composition Differences

Aluminum alloys primarily consist of aluminum combined with elements such as copper, magnesium, silicon, and zinc, enhancing strength and corrosion resistance. Titanium alloys are mainly composed of titanium with smaller amounts of aluminum, vanadium, and iron, providing superior strength-to-weight ratio and corrosion resistance compared to aluminum alloys. The distinct chemical compositions result in notable differences in mechanical properties and applications across aerospace and biomedical industries.

Mechanical Properties Comparison

Aluminum alloys offer excellent strength-to-weight ratios with tensile strengths typically ranging from 200 to 600 MPa, while titanium alloys exhibit superior mechanical properties with tensile strengths often exceeding 900 MPa. Titanium alloys provide greater fatigue resistance and higher Young's modulus, approximately 110 GPa compared to aluminum's 70 GPa, making them ideal for high-stress applications. Aluminum alloys are more ductile and easier to machine, but titanium alloys deliver better corrosion resistance and maintain mechanical integrity at elevated temperatures.

Weight and Density Analysis

Aluminum alloy typically has a density around 2.7 g/cm3, making it significantly lighter than titanium alloy, which has a density of approximately 4.5 g/cm3. This lower density translates to aluminum alloys being preferred in applications where weight reduction is critical, such as in aerospace and automotive industries. Despite titanium alloys' higher density, their superior strength-to-weight ratio often compensates, allowing for thinner sections and overall weight savings in high-performance components.

Corrosion Resistance: Aluminum vs Titanium

Titanium alloys exhibit superior corrosion resistance compared to aluminum alloys due to the formation of a stable, protective oxide layer that withstands aggressive environments such as seawater and acidic conditions. Aluminum alloys, while resistant to corrosion in many atmospheric environments, are more susceptible to pitting and galvanic corrosion, especially in chloride-rich or alkaline solutions. The inherent durability of titanium alloys makes them ideal for marine, chemical processing, and aerospace applications where long-term corrosion resistance is critical.

Manufacturing and Processing Methods

Aluminum alloys benefit from casting, forging, and extrusion techniques due to their lower melting point and excellent machinability, enabling cost-effective mass production. Titanium alloys require advanced processes like powder metallurgy and vacuum arc remelting to handle their high melting point and reactivity, ensuring superior strength and corrosion resistance. Specialized machining methods, including cryogenic and ultrasonic machining, improve titanium alloy workability by minimizing tool wear and thermal damage during manufacturing.

Cost and Economic Considerations

Aluminum alloys generally offer a lower cost per pound compared to titanium alloys, making them more economically viable for applications requiring large volumes or budget constraints. Titanium alloys, while significantly more expensive due to raw material scarcity and complex processing, provide higher strength-to-weight ratios and corrosion resistance, justifying their cost in critical aerospace and medical industries. Procurement decisions often balance these economic factors against performance requirements, with aluminum favored for cost-sensitive projects.

Common Applications in Industry

Aluminum alloy is widely used in the aerospace industry for aircraft frames and automotive manufacturing due to its lightweight and corrosion resistance. Titanium alloy finds common applications in medical implants, aerospace components, and chemical processing plants because of its superior strength-to-weight ratio and biocompatibility. Both alloys are critical in marine engineering, with aluminum favored for shipbuilding and titanium used in submersible vessels and offshore structures.

Sustainability and Recycling Aspects

Aluminum alloys demonstrate superior sustainability due to their high recyclability, with up to 95% of aluminum being recyclable without loss of properties, significantly reducing energy consumption and greenhouse gas emissions during production. Titanium alloys, while offering exceptional strength-to-weight ratios, present challenges in recycling due to complex processing and lower recycling rates, impacting their overall environmental footprint. The aluminum industry's established recycling infrastructure ensures a more circular lifecycle compared to titanium alloys, making aluminum a more sustainable choice in applications prioritizing environmental responsibility.

Choosing the Right Alloy for Your Project

Aluminum alloys offer excellent lightweight properties and corrosion resistance, making them ideal for applications requiring easy machinability and cost-efficiency. Titanium alloys provide superior strength-to-weight ratio and exceptional durability in extreme environments such as aerospace and biomedical implants. Selecting the right alloy depends on balancing factors like mechanical performance, environmental conditions, and budget constraints to optimize project outcomes.

Aluminum Alloy vs Titanium Alloy Infographic

materialdif.com

materialdif.com