Lead-free alloys offer improved environmental safety and comply with stringent regulatory standards compared to leaded alloys, which contain toxic lead posing health risks. These lead-free alternatives often provide comparable mechanical properties and corrosion resistance, making them suitable for diverse industrial applications. The transition to lead-free alloys supports sustainable manufacturing while maintaining performance reliability.

Table of Comparison

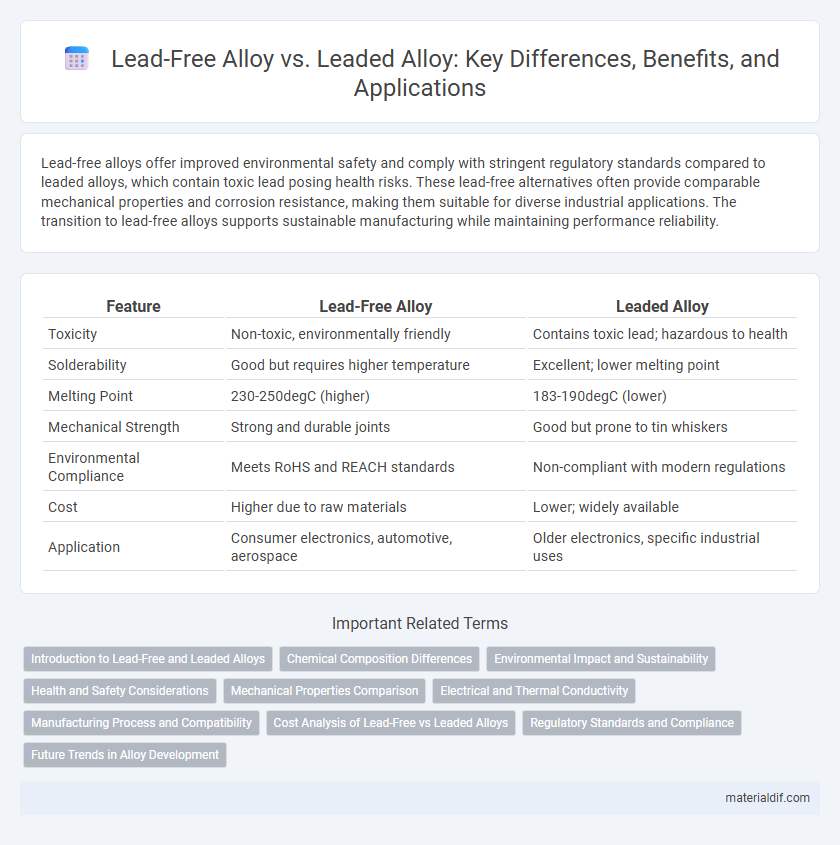

| Feature | Lead-Free Alloy | Leaded Alloy |

|---|---|---|

| Toxicity | Non-toxic, environmentally friendly | Contains toxic lead; hazardous to health |

| Solderability | Good but requires higher temperature | Excellent; lower melting point |

| Melting Point | 230-250degC (higher) | 183-190degC (lower) |

| Mechanical Strength | Strong and durable joints | Good but prone to tin whiskers |

| Environmental Compliance | Meets RoHS and REACH standards | Non-compliant with modern regulations |

| Cost | Higher due to raw materials | Lower; widely available |

| Application | Consumer electronics, automotive, aerospace | Older electronics, specific industrial uses |

Introduction to Lead-Free and Leaded Alloys

Lead-free alloys, primarily composed of tin, copper, and silver, offer enhanced environmental safety by eliminating toxic lead content found in traditional leaded alloys, which typically contain 2-5% lead to improve machinability and durability. Leaded alloys have been widely used in applications requiring superior corrosion resistance and thermal conductivity, while lead-free alternatives are increasingly favored in electronics and plumbing industries due to regulatory restrictions such as RoHS. The shift to lead-free alloys balances performance requirements with health and environmental concerns, driving innovation in alloy composition and processing techniques.

Chemical Composition Differences

Lead-free alloys primarily consist of elements such as tin, silver, and copper, avoiding lead to meet environmental and health regulations. In contrast, leaded alloys contain a significant percentage of lead, typically around 30-40%, which enhances machinability and reduces melting points. The chemical composition differences affect properties like toxicity, melting temperature, and mechanical performance, influencing their respective industrial applications.

Environmental Impact and Sustainability

Lead-free alloys significantly reduce environmental contamination by eliminating toxic lead emissions during manufacturing and disposal, promoting safer recycling processes. Their increased use supports sustainable development goals by minimizing soil and water pollution, protecting ecosystems and human health. In contrast, leaded alloys pose ongoing environmental risks due to lead toxicity, hindering regulatory compliance and ecological preservation efforts.

Health and Safety Considerations

Lead-free alloys significantly reduce health risks by eliminating exposure to toxic lead, which is known to cause neurological damage and respiratory issues. In comparison, leaded alloys pose serious safety hazards during melting and handling, releasing harmful lead fumes and dust that necessitate stringent protective measures. Utilizing lead-free alloys enhances workplace safety by minimizing hazardous emissions and complying with regulatory standards aimed at protecting workers' health.

Mechanical Properties Comparison

Lead-free alloys typically exhibit higher tensile strength and improved corrosion resistance compared to leaded alloys, enhancing durability in mechanical applications. Leaded alloys often offer superior machinability and lower melting points, which can be advantageous in manufacturing processes requiring precision and ease of shaping. The mechanical performance of lead-free alloys is increasingly favored in industries prioritizing environmental compliance and long-term structural integrity.

Electrical and Thermal Conductivity

Lead-free alloys typically exhibit higher electrical and thermal conductivity compared to leaded alloys, making them more efficient for applications requiring rapid heat dissipation and minimal electrical resistance. The absence of lead enhances the purity and homogeneity of the metal matrix, resulting in improved conductive pathways. Leaded alloys, while offering better machinability and corrosion resistance, tend to have lower conductivity due to lead's inherent properties disrupting electron flow.

Manufacturing Process and Compatibility

Lead-free alloys require higher melting temperatures and more precise control during the manufacturing process compared to leaded alloys, which melt at lower temperatures and are easier to work with. Lead-free alloys are compatible with modern electronic manufacturing standards due to environmental regulations like RoHS, while leaded alloys are often preferred for legacy systems that demand superior mechanical strength and thermal fatigue resistance. The shift to lead-free alloys drives the need for updated soldering equipment and processes to ensure product reliability and compliance.

Cost Analysis of Lead-Free vs Leaded Alloys

Lead-free alloys generally incur higher raw material costs due to the use of more expensive metals like tin, silver, or copper, impacting overall production expenses. Leaded alloys benefit from lower material costs and easier processing, reducing manufacturing time and energy consumption. However, regulatory compliance and environmental disposal costs associated with leaded materials can increase long-term expenses, making lead-free alloys potentially more cost-effective in sustainable production.

Regulatory Standards and Compliance

Lead-free alloys comply with stringent global regulatory standards such as RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals), minimizing environmental and health risks by eliminating toxic lead content. Leaded alloys, while traditionally used for superior mechanical properties, face increasing restrictions and phase-outs in many industries due to their hazardous lead content, necessitating compliance adaptations or substitution. Manufacturers prioritize lead-free alloys to meet evolving international compliance requirements, reduce liability, and enhance sustainability in their supply chains.

Future Trends in Alloy Development

Future trends in alloy development emphasize lead-free alloys due to increasing environmental regulations and health concerns associated with lead toxicity. Advancements in material science aim to enhance the mechanical properties and corrosion resistance of lead-free alloys to meet or exceed the performance of traditional leaded alloys. Innovations in alloy composition and processing methods are driving sustainable solutions that support eco-friendly manufacturing and recycling practices.

Lead-free alloy vs Leaded alloy Infographic

materialdif.com

materialdif.com