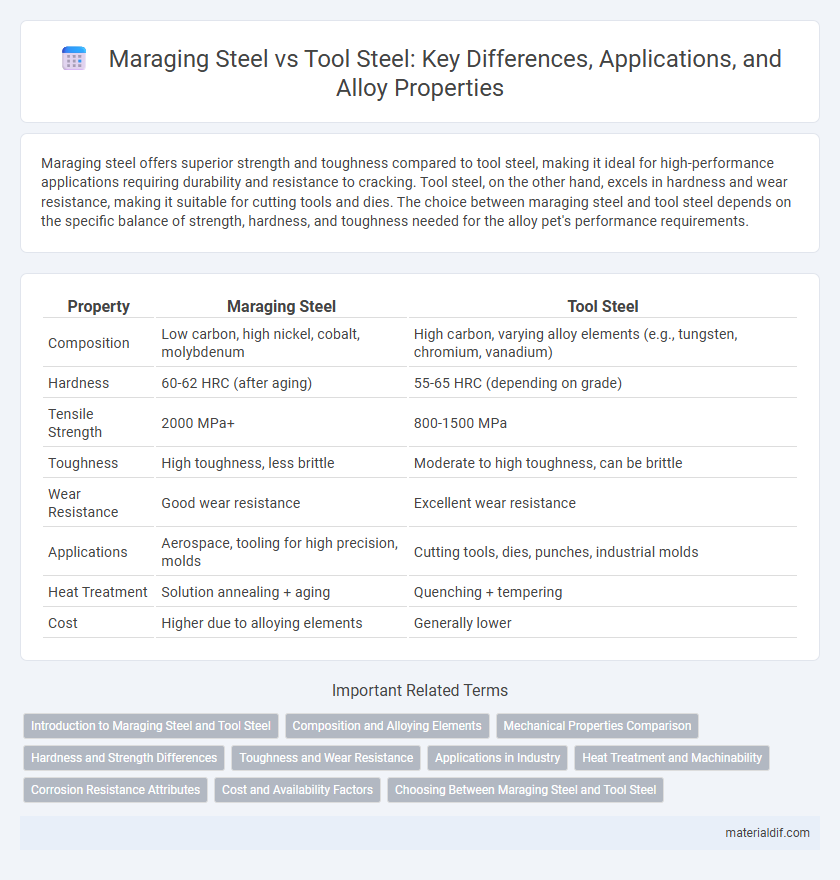

Maraging steel offers superior strength and toughness compared to tool steel, making it ideal for high-performance applications requiring durability and resistance to cracking. Tool steel, on the other hand, excels in hardness and wear resistance, making it suitable for cutting tools and dies. The choice between maraging steel and tool steel depends on the specific balance of strength, hardness, and toughness needed for the alloy pet's performance requirements.

Table of Comparison

| Property | Maraging Steel | Tool Steel |

|---|---|---|

| Composition | Low carbon, high nickel, cobalt, molybdenum | High carbon, varying alloy elements (e.g., tungsten, chromium, vanadium) |

| Hardness | 60-62 HRC (after aging) | 55-65 HRC (depending on grade) |

| Tensile Strength | 2000 MPa+ | 800-1500 MPa |

| Toughness | High toughness, less brittle | Moderate to high toughness, can be brittle |

| Wear Resistance | Good wear resistance | Excellent wear resistance |

| Applications | Aerospace, tooling for high precision, molds | Cutting tools, dies, punches, industrial molds |

| Heat Treatment | Solution annealing + aging | Quenching + tempering |

| Cost | Higher due to alloying elements | Generally lower |

Introduction to Maraging Steel and Tool Steel

Maraging steel is a high-strength alloy primarily composed of iron and nickel, known for its exceptional toughness, malleability, and ability to achieve high yield strength through aging heat treatment. Tool steel encompasses a variety of carbon and alloy steels specifically formulated for durability, hardness, and resistance to abrasion and deformation, making it ideal for cutting, molding, and stamping applications. Both alloys play critical roles in industrial manufacturing, with maraging steel favored for aerospace and tooling requiring superior strength, while tool steels are essential in producing precise, wear-resistant tools.

Composition and Alloying Elements

Maraging steel primarily consists of iron, nickel (15-25%), cobalt, molybdenum, and titanium, with very low carbon content below 0.03%, enabling superior strength through age-hardening rather than carbon hardening. Tool steel features higher carbon levels (typically 0.5-1.5%) combined with elements like chromium, vanadium, tungsten, and molybdenum, optimizing wear resistance and hardness for cutting and shaping tools. The distinct compositions reflect maraging steel's emphasis on toughness and ductility through precipitation hardening, while tool steel focuses on hardness and abrasion resistance via carbides formed by carbon and alloying elements.

Mechanical Properties Comparison

Maraging steel exhibits exceptional tensile strength ranging from 1400 to 2500 MPa, significantly outperforming most tool steels, which generally have tensile strengths between 800 to 1200 MPa. Its superior toughness and ductility enable better resistance to crack propagation, whereas tool steel offers higher hardness and wear resistance suited for cutting and forming applications. Heat-treated maraging steel maintains strength with moderate hardness levels around 50-60 HRC, while hardened tool steel can reach hardness values exceeding 60 HRC but at the cost of reduced toughness.

Hardness and Strength Differences

Maraging steel exhibits superior hardness and strength compared to traditional tool steel due to its unique iron-nickel alloy composition enriched with cobalt, molybdenum, and titanium, which enables age hardening. Tool steel, typically composed of varied carbon and alloy contents, offers excellent toughness and wear resistance but generally falls short in achieving the ultra-high strength and hardness levels attainable by maraging steels. The hardness of maraging steel can exceed 60 HRC after aging, while tool steel hardness usually ranges between 50-62 HRC depending on the grade and heat treatment applied.

Toughness and Wear Resistance

Maraging steel offers superior toughness due to its low carbon content and aging heat treatment, resulting in high strength and excellent crack resistance. Tool steel provides exceptional wear resistance because of its higher carbon and alloying elements, making it ideal for cutting and forming applications. Comparing both, maraging steel excels in impact toughness while tool steel outperforms in durability under abrasive conditions.

Applications in Industry

Maraging steel offers exceptional strength and toughness, making it ideal for aerospace components, high-performance tooling, and missile skins where durability under stress is critical. Tool steel excels in cutting, molding, and stamping applications due to its wear resistance and ability to retain hardness at elevated temperatures. Both alloys find crucial roles in manufacturing gears, dies, and heavy machinery parts, but maraging steel is preferred in high-stress environments, while tool steel is favored for precision tools and dies.

Heat Treatment and Machinability

Maraging steel undergoes a specialized heat treatment process involving solution annealing followed by aging, which significantly enhances its strength and toughness without losing ductility, while tool steel typically requires quenching and tempering to achieve hardness and wear resistance. In terms of machinability, maraging steel offers superior ease of machining in its annealed state, allowing for intricate tooling applications, whereas tool steel generally presents more challenges due to its higher hardness post-heat treatment. The unique aging process of maraging steel also results in less distortion during machining compared to the often brittle nature of hardened tool steel.

Corrosion Resistance Attributes

Maraging steel exhibits superior corrosion resistance compared to traditional tool steel due to its low carbon content and high nickel concentration, which enhance its resistance to oxidation and rust. Tool steel, while offering excellent hardness and wear resistance, generally lacks the corrosion-resistant properties inherent in maraging steel, making it susceptible to surface degradation in harsh environments. The alloying elements in maraging steel, such as cobalt, molybdenum, and titanium, contribute to its enhanced chemical stability, making it the preferred choice for applications requiring durability in corrosive conditions.

Cost and Availability Factors

Maraging steel generally commands a higher price than tool steel due to its specialized high-nickel content and complex aging process, which contribute to superior strength and toughness. Availability of maraging steel is more limited, often requiring custom orders from specialized suppliers, while tool steel is widely produced and readily accessible in various grades for diverse industrial applications. Cost-efficiency in production favors tool steel for large-scale manufacturing, whereas maraging steel is preferred for high-performance components despite its premium price and niche availability.

Choosing Between Maraging Steel and Tool Steel

Maraging steel offers superior strength and toughness due to its unique aging process, making it ideal for high-performance applications like aerospace and tooling that require excellent dimensional stability. Tool steel provides a broad range of hardness and wear resistance options, suitable for cutting, shaping, and forming tools in industrial manufacturing. Selecting between maraging steel and tool steel depends on balancing factors such as mechanical properties, heat treatment capabilities, and specific application demands.

Maraging Steel vs Tool Steel Infographic

materialdif.com

materialdif.com