Galvanic corrosion occurs when two dissimilar metals are electrically connected in the presence of an electrolyte, causing one metal to corrode faster while protecting the other. Uniform corrosion, by contrast, happens evenly across the entire surface of a single alloy exposed to a corrosive environment. Understanding the differences between galvanic and uniform corrosion is essential for selecting appropriate alloys and protective measures in various industrial applications.

Table of Comparison

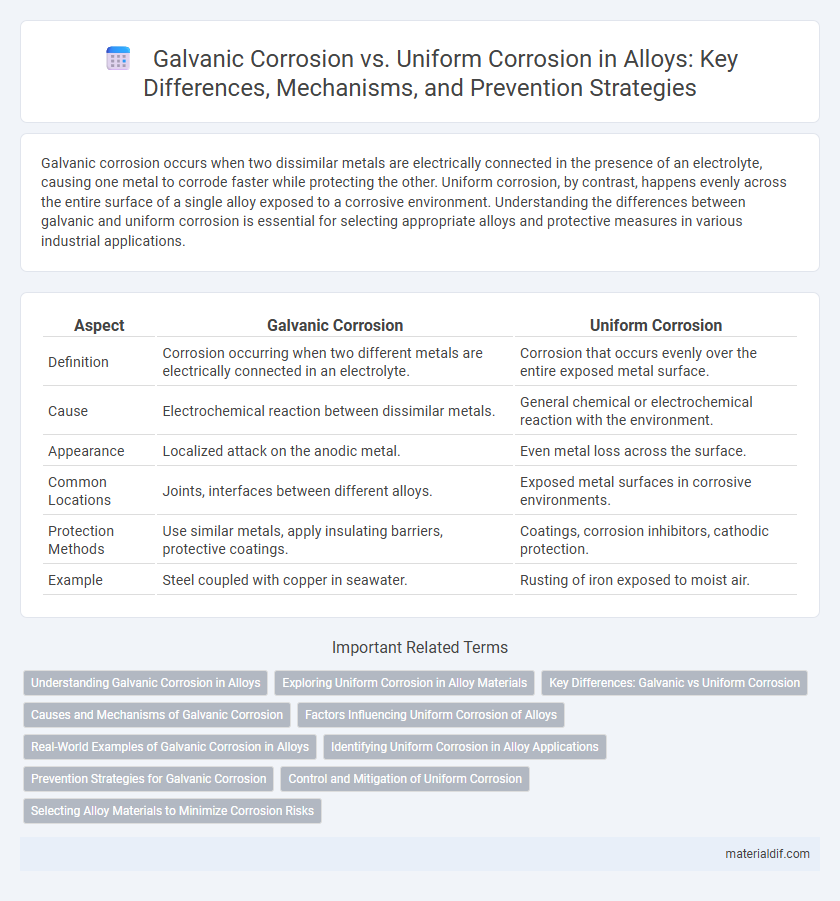

| Aspect | Galvanic Corrosion | Uniform Corrosion |

|---|---|---|

| Definition | Corrosion occurring when two different metals are electrically connected in an electrolyte. | Corrosion that occurs evenly over the entire exposed metal surface. |

| Cause | Electrochemical reaction between dissimilar metals. | General chemical or electrochemical reaction with the environment. |

| Appearance | Localized attack on the anodic metal. | Even metal loss across the surface. |

| Common Locations | Joints, interfaces between different alloys. | Exposed metal surfaces in corrosive environments. |

| Protection Methods | Use similar metals, apply insulating barriers, protective coatings. | Coatings, corrosion inhibitors, cathodic protection. |

| Example | Steel coupled with copper in seawater. | Rusting of iron exposed to moist air. |

Understanding Galvanic Corrosion in Alloys

Galvanic corrosion occurs when two dissimilar metals in an alloy system create an electrochemical cell, leading to accelerated corrosion of the more anodic metal. Unlike uniform corrosion, which affects a metal surface evenly, galvanic corrosion targets specific areas where metal contact and electrolyte presence promote localized degradation. Understanding the electrochemical potential differences between alloy components is crucial for preventing galvanic corrosion and enhancing alloy durability in various industrial applications.

Exploring Uniform Corrosion in Alloy Materials

Uniform corrosion in alloy materials occurs evenly across the surface, leading to a gradual and predictable material loss that helps in assessing the alloy's lifespan. This type of corrosion typically results from the alloy's overall exposure to a corrosive environment, without localized electrochemical differences causing accelerated damage. Understanding the uniform corrosion rates of alloys like stainless steel or aluminum alloys aids in selecting materials with enhanced durability for construction, marine, and industrial applications.

Key Differences: Galvanic vs Uniform Corrosion

Galvanic corrosion occurs when two dissimilar metals in electrical contact corrode at different rates due to their electrochemical potential differences, often causing localized damage to the less noble alloy. Uniform corrosion, by contrast, affects the entire surface of a single alloy evenly, leading to a consistent thinning over time without preferential attack. Understanding these differences is critical for alloy selection and protection strategies in environments where mixed metals or harsh conditions are present.

Causes and Mechanisms of Galvanic Corrosion

Galvanic corrosion occurs when two dissimilar metals or alloys are in electrical contact within an electrolyte, creating a galvanic cell where the more anodic metal corrodes preferentially. This electrochemical mechanism accelerates metal degradation due to differences in electrode potentials, causing localized metal dissolution at the anode and protection at the cathode. Uniform corrosion, by contrast, involves consistent metal loss across the surface without electrical coupling or differential potentials.

Factors Influencing Uniform Corrosion of Alloys

Uniform corrosion of alloys is primarily influenced by environmental factors such as temperature, pH, and the presence of oxidizing agents, which accelerate metal dissolution evenly across the surface. Alloy composition, including the type and proportion of constituent metals, significantly affects corrosion resistance by altering electrochemical stability and passive film formation. Surface conditions like roughness and mechanical damage also impact corrosion rates by providing active sites for uniform corrosion to initiate and propagate.

Real-World Examples of Galvanic Corrosion in Alloys

Galvanic corrosion occurs when two dissimilar alloys, such as aluminum and copper, are electrically connected in a corrosive environment, causing accelerated deterioration of the more anodic metal. Real-world examples include marine structures where stainless steel fasteners in aluminum hulls corrode rapidly due to seawater acting as an electrolyte. This contrasts with uniform corrosion, where metal degradation occurs evenly across surfaces without differential electrical potential.

Identifying Uniform Corrosion in Alloy Applications

Uniform corrosion in alloy applications manifests as a consistent, even material loss across the entire exposed surface, often identified by a smooth, dull appearance without localized pits or crevices. It differs from galvanic corrosion, which occurs at the interface of two dissimilar metals, causing localized accelerated degradation. Detecting uniform corrosion involves regular inspection for generalized thinning or color changes on alloys like stainless steel or aluminum, ensuring timely maintenance to prevent structural failures.

Prevention Strategies for Galvanic Corrosion

Galvanic corrosion occurs when two dissimilar metals in electrical contact are exposed to an electrolyte, causing accelerated metal degradation, unlike uniform corrosion which affects surfaces evenly. Effective prevention strategies for galvanic corrosion include using compatible alloys, applying insulating coatings or barriers, and incorporating sacrificial anodes such as zinc or magnesium to protect the more noble metal. Controlling environmental factors like moisture and electrolyte concentration further reduces galvanic corrosion risks in alloy applications.

Control and Mitigation of Uniform Corrosion

Uniform corrosion can be effectively controlled and mitigated in alloys through the application of protective coatings, corrosion inhibitors, and proper material selection based on corrosion resistance properties. Environmental control, such as reducing exposure to corrosive agents like moisture and aggressive chemicals, also plays a critical role in minimizing uniform corrosion rates. Routine maintenance and monitoring enable early detection and timely intervention, significantly extending the service life of alloy components.

Selecting Alloy Materials to Minimize Corrosion Risks

Selecting alloy materials to minimize corrosion risks requires understanding the difference between galvanic corrosion and uniform corrosion. Alloys with similar electrochemical potentials reduce galvanic corrosion by preventing galvanic cell formation, while corrosion-resistant compositions such as stainless steel or nickel-based alloys enhance resistance against uniform corrosion. Proper alloy selection involves analyzing environmental conditions, including electrolyte presence and temperature, to ensure compatibility and durability in service.

Galvanic Corrosion vs Uniform Corrosion Infographic

materialdif.com

materialdif.com