Zinc alloys offer superior strength and corrosion resistance compared to tin alloys, making them ideal for structural components and durable applications. Tin alloys provide excellent solderability and good electrical conductivity, which makes them suitable for electronic and decorative uses. Choosing between zinc and tin alloys depends on the specific requirements for mechanical performance and environmental exposure in the intended application.

Table of Comparison

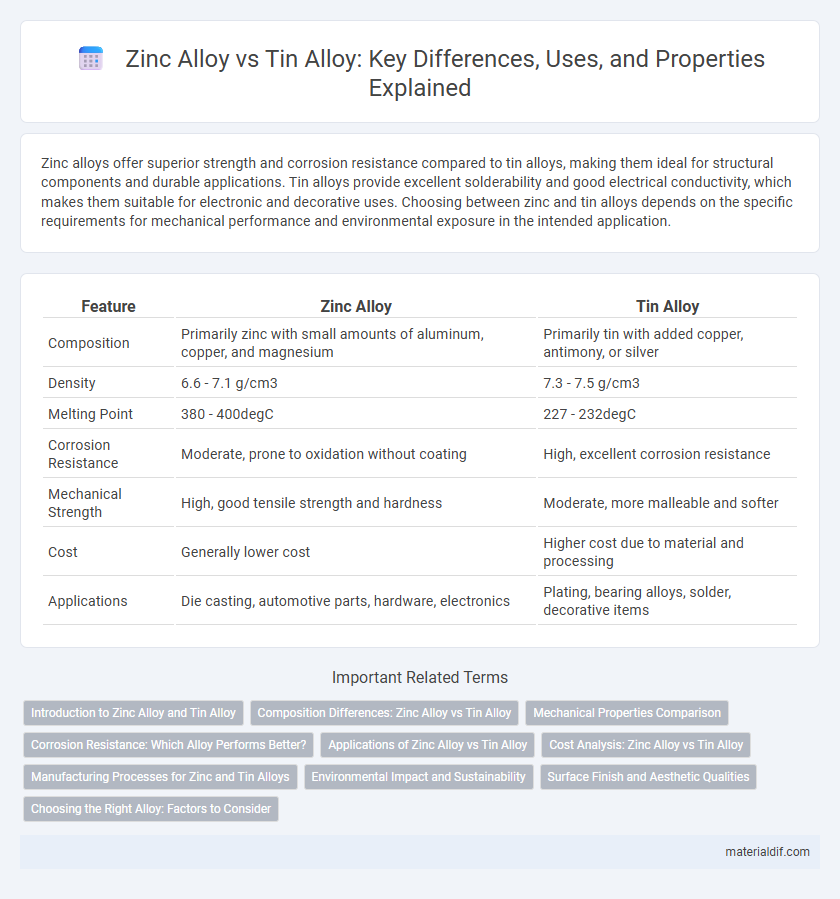

| Feature | Zinc Alloy | Tin Alloy |

|---|---|---|

| Composition | Primarily zinc with small amounts of aluminum, copper, and magnesium | Primarily tin with added copper, antimony, or silver |

| Density | 6.6 - 7.1 g/cm3 | 7.3 - 7.5 g/cm3 |

| Melting Point | 380 - 400degC | 227 - 232degC |

| Corrosion Resistance | Moderate, prone to oxidation without coating | High, excellent corrosion resistance |

| Mechanical Strength | High, good tensile strength and hardness | Moderate, more malleable and softer |

| Cost | Generally lower cost | Higher cost due to material and processing |

| Applications | Die casting, automotive parts, hardware, electronics | Plating, bearing alloys, solder, decorative items |

Introduction to Zinc Alloy and Tin Alloy

Zinc alloy is a versatile metal composite composed primarily of zinc combined with small amounts of aluminum, copper, and magnesium, offering excellent corrosion resistance and strength for industrial applications. Tin alloy, consisting mainly of tin with elements like copper, antimony, and silver, provides superior solderability, non-toxicity, and low melting points ideal for electrical components and coatings. Both alloys cater to diverse manufacturing needs but differ significantly in mechanical properties and usage environments.

Composition Differences: Zinc Alloy vs Tin Alloy

Zinc alloy primarily consists of zinc mixed with small amounts of aluminum, copper, and magnesium, providing high strength and corrosion resistance. Tin alloy mainly comprises tin combined with metals like copper, antimony, and sometimes silver, offering excellent solderability and low melting points. The key compositional difference lies in zinc alloys being zinc-based for durability, while tin alloys focus on tin content for malleability and ease of casting.

Mechanical Properties Comparison

Zinc alloy exhibits higher tensile strength and better impact resistance compared to tin alloy, making it more suitable for durable and load-bearing applications. Tin alloy offers superior corrosion resistance and better solderability due to its lower melting point and inherent softness. The choice between zinc and tin alloys depends on the specific mechanical property requirements such as strength versus corrosion protection in manufacturing processes.

Corrosion Resistance: Which Alloy Performs Better?

Zinc alloy exhibits moderate corrosion resistance, often enhanced with protective coatings to prevent oxidation and deterioration in humid or acidic environments. Tin alloy stands out for superior corrosion resistance due to its natural ability to form a stable oxide layer, making it ideal for applications exposed to moisture and corrosive substances. When comparing zinc alloy vs tin alloy in terms of corrosion resistance, tin alloy generally performs better, offering longer-lasting protection and reduced maintenance in corrosive conditions.

Applications of Zinc Alloy vs Tin Alloy

Zinc alloys are widely used in automotive parts, die-casting for electrical components, and hardware due to their strength and corrosion resistance, making them ideal for structural and protective applications. Tin alloys find extensive use in soldering, plating, and manufacturing of bearings, benefiting from their excellent corrosion resistance and low melting points, which suits electronics and marine environments. The choice between zinc and tin alloys depends heavily on specific application needs such as mechanical strength, electrical conductivity, and environmental exposure.

Cost Analysis: Zinc Alloy vs Tin Alloy

Zinc alloy is generally more cost-effective than tin alloy due to lower raw material prices and higher availability, resulting in reduced manufacturing expenses. Tin alloy, while offering superior corrosion resistance and solderability, typically incurs higher production costs because of more expensive tin content and complex processing requirements. Businesses often choose zinc alloys for budget-sensitive projects where mechanical strength and cost efficiency are prioritized over the premium benefits of tin alloys.

Manufacturing Processes for Zinc and Tin Alloys

Zinc alloys are commonly manufactured using die casting, which allows for high precision, fast cycle times, and excellent surface finish, making them ideal for complex shapes and mass production. Tin alloys typically undergo casting or machining processes suited for their low melting points and excellent corrosion resistance, often used in electronics and coatings. The choice of manufacturing process directly impacts the mechanical properties and application scope of both zinc and tin alloys.

Environmental Impact and Sustainability

Zinc alloys typically offer better environmental sustainability due to zinc's natural abundance and lower energy consumption during extraction and processing compared to tin, which is scarcer and often associated with higher ecological damage. Tin alloys can pose higher environmental risks due to mining practices that contribute to deforestation and soil degradation, along with potential toxic waste generation during smelting. Choosing zinc alloys supports a reduced carbon footprint and aligns with sustainable manufacturing practices, promoting eco-friendly product development.

Surface Finish and Aesthetic Qualities

Zinc alloys typically offer a smoother surface finish with higher corrosion resistance, making them ideal for durable and visually appealing products. Tin alloys provide a bright, silver-like appearance with excellent solderability and natural resistance to oxidation, enhancing aesthetic qualities in decorative applications. The choice between zinc and tin alloys depends on the specific requirements for surface durability, luster, and environmental exposure.

Choosing the Right Alloy: Factors to Consider

Selecting the right alloy between zinc alloy and tin alloy depends on factors such as corrosion resistance, mechanical strength, and cost-effectiveness. Zinc alloys offer superior durability and hardness, ideal for structural applications, while tin alloys excel in soldering and electrical conductivity due to their low melting point and malleability. Evaluating application-specific requirements like environmental exposure and performance needs ensures optimal alloy choice for longevity and functionality.

Zinc Alloy vs Tin Alloy Infographic

materialdif.com

materialdif.com