Nickel alloys offer excellent corrosion resistance and high-temperature strength, making them ideal for chemical processing and aerospace applications. Cobalt alloys provide superior wear resistance and maintain mechanical integrity at extremely high temperatures, suited for medical implants and turbine blades. Choosing between nickel and cobalt alloys depends on the specific environmental conditions and performance requirements.

Table of Comparison

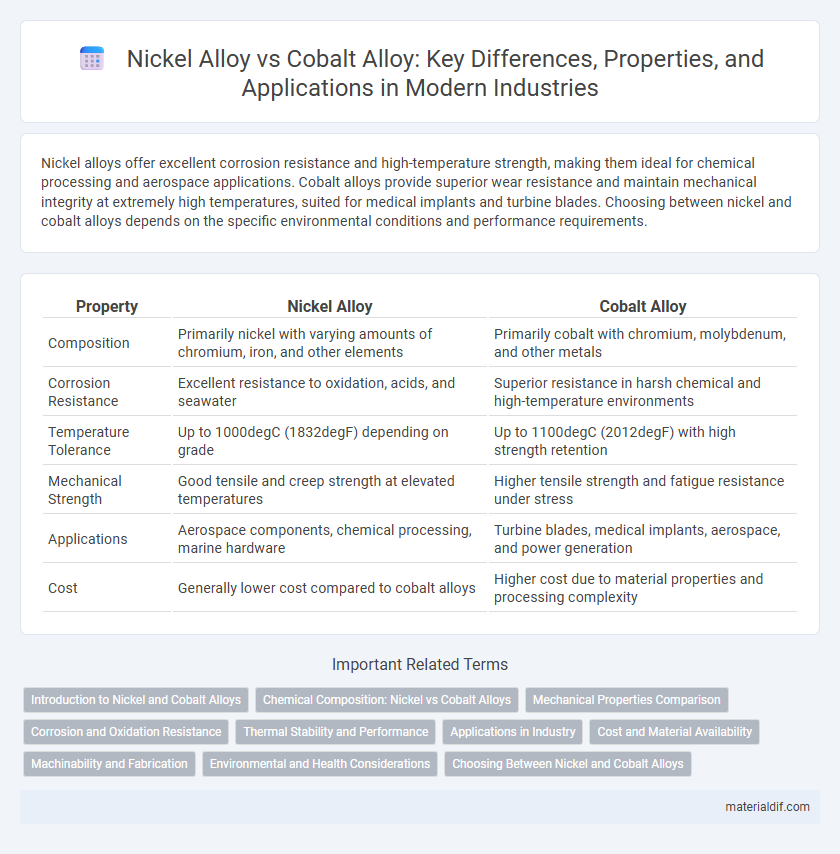

| Property | Nickel Alloy | Cobalt Alloy |

|---|---|---|

| Composition | Primarily nickel with varying amounts of chromium, iron, and other elements | Primarily cobalt with chromium, molybdenum, and other metals |

| Corrosion Resistance | Excellent resistance to oxidation, acids, and seawater | Superior resistance in harsh chemical and high-temperature environments |

| Temperature Tolerance | Up to 1000degC (1832degF) depending on grade | Up to 1100degC (2012degF) with high strength retention |

| Mechanical Strength | Good tensile and creep strength at elevated temperatures | Higher tensile strength and fatigue resistance under stress |

| Applications | Aerospace components, chemical processing, marine hardware | Turbine blades, medical implants, aerospace, and power generation |

| Cost | Generally lower cost compared to cobalt alloys | Higher cost due to material properties and processing complexity |

Introduction to Nickel and Cobalt Alloys

Nickel alloys exhibit excellent corrosion resistance and high-temperature strength, making them ideal for aerospace, chemical processing, and power generation applications. Cobalt alloys offer superior wear resistance and maintain mechanical properties at elevated temperatures, commonly used in medical implants, gas turbines, and cutting tools. Both nickel and cobalt alloys provide critical performance advantages in demanding environments, with nickel excelling in oxidation resistance and cobalt in hardness and thermal stability.

Chemical Composition: Nickel vs Cobalt Alloys

Nickel alloys primarily contain nickel as the base metal, typically ranging from 50% to 70%, complemented by elements such as chromium, iron, and molybdenum, enhancing corrosion resistance and mechanical strength. Cobalt alloys, in contrast, feature cobalt as the main element, often exceeding 60%, with significant amounts of chromium, nickel, and carbon to improve hardness, wear resistance, and high-temperature stability. The distinct chemical compositions of nickel and cobalt alloys directly influence their performance characteristics in applications like aerospace, medical implants, and power generation.

Mechanical Properties Comparison

Nickel alloys exhibit superior corrosion resistance and excellent tensile strength, making them ideal for high-temperature and aggressive chemical environments. Cobalt alloys, in contrast, provide exceptional wear resistance and maintain mechanical strength at higher temperatures, especially in aerospace and medical applications. Both materials offer high fatigue resistance, but nickel alloys typically outperform cobalt alloys in ductility and impact toughness.

Corrosion and Oxidation Resistance

Nickel alloys exhibit superior corrosion resistance in acidic and chloride-containing environments due to the formation of a stable passive oxide layer. Cobalt alloys offer enhanced oxidation resistance at elevated temperatures, making them ideal for high-temperature applications such as gas turbines and jet engines. Both alloys provide excellent durability, but nickel alloys excel in resisting chemical corrosion, while cobalt alloys perform better against oxidation.

Thermal Stability and Performance

Nickel alloys exhibit superior thermal stability with melting points typically above 1300degC, making them ideal for high-temperature applications such as jet engines and gas turbines. Cobalt alloys offer excellent thermal performance, particularly in oxidation and corrosion resistance, maintaining strength at temperatures up to 1150degC. The choice between nickel and cobalt alloys depends on specific operational environments, where nickel alloys favor extreme heat resistance while cobalt alloys excel in wear and corrosion resistance under moderate high temperatures.

Applications in Industry

Nickel alloys are extensively used in chemical processing, aerospace, and power generation industries due to their exceptional resistance to corrosion and high-temperature strength. Cobalt alloys find critical applications in medical implants, jet engine components, and cutting tools because of their superior wear resistance and ability to maintain mechanical properties at elevated temperatures. Both alloys play vital roles in harsh environments, with nickel alloys favored for oxidation resistance and cobalt alloys chosen for their hardness and thermal stability.

Cost and Material Availability

Nickel alloys generally offer a lower cost compared to cobalt alloys, making them more economically viable for large-scale industrial applications. Nickel's abundant availability and widespread mining operations ensure consistent supply chains, whereas cobalt's limited geographic sources and higher demand drive up its material costs. Industries often choose nickel alloys for cost-sensitive projects, while cobalt alloys are reserved for specialized uses requiring superior corrosion resistance and high-temperature stability.

Machinability and Fabrication

Nickel alloys generally offer superior machinability compared to cobalt alloys, enabling easier cutting, drilling, and shaping during fabrication. Cobalt alloys, although harder and more wear-resistant, present challenges in machining due to their toughness and work-hardening characteristics. In fabrication processes, nickel alloys allow for more efficient manufacturing cycles with reduced tool wear, while cobalt alloys often require specialized tooling and slower speeds to maintain precision.

Environmental and Health Considerations

Nickel alloys pose environmental challenges due to the potential release of nickel ions, which can cause allergic reactions and respiratory issues in exposed individuals. Cobalt alloys, while offering superior corrosion resistance, contain cobalt compounds classified as possible carcinogens, raising concerns in manufacturing and handling processes. Proper ventilation, protective equipment, and responsible disposal practices are essential to mitigate health risks and environmental impact associated with both nickel and cobalt alloys.

Choosing Between Nickel and Cobalt Alloys

Nickel alloys offer superior corrosion resistance and excellent mechanical strength at moderate temperatures, making them ideal for chemical processing and aerospace applications. Cobalt alloys provide exceptional wear resistance and maintain structural integrity in extreme high-temperature environments, often used in turbine blades and medical implants. Selecting between nickel and cobalt alloys depends on specific performance requirements such as temperature tolerance, corrosion resistance, and application environment.

Nickel Alloy vs Cobalt Alloy Infographic

materialdif.com

materialdif.com