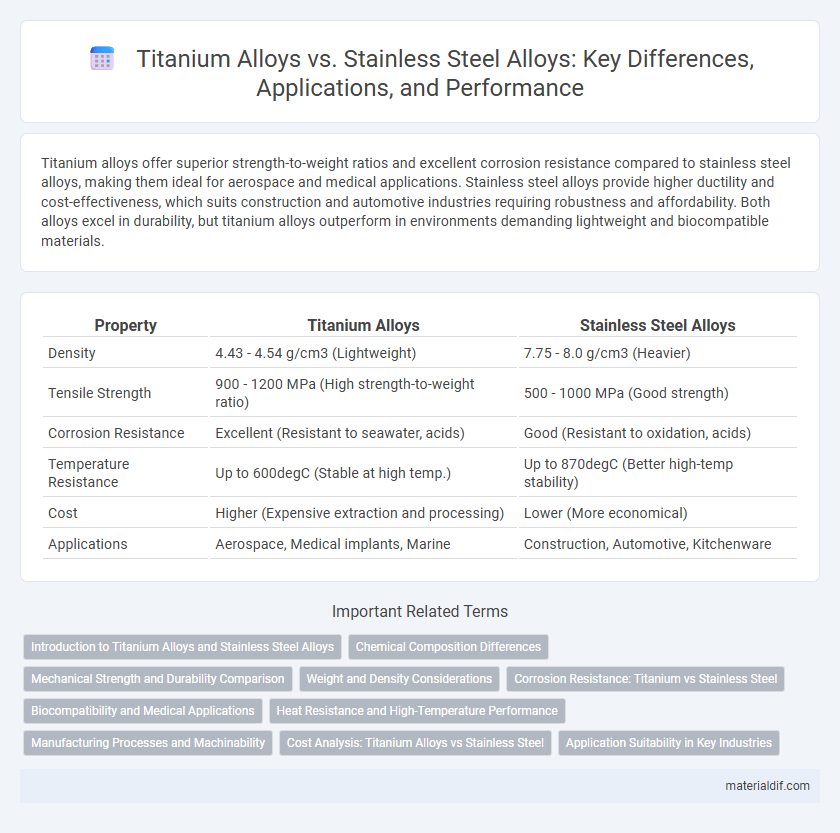

Titanium alloys offer superior strength-to-weight ratios and excellent corrosion resistance compared to stainless steel alloys, making them ideal for aerospace and medical applications. Stainless steel alloys provide higher ductility and cost-effectiveness, which suits construction and automotive industries requiring robustness and affordability. Both alloys excel in durability, but titanium alloys outperform in environments demanding lightweight and biocompatible materials.

Table of Comparison

| Property | Titanium Alloys | Stainless Steel Alloys |

|---|---|---|

| Density | 4.43 - 4.54 g/cm3 (Lightweight) | 7.75 - 8.0 g/cm3 (Heavier) |

| Tensile Strength | 900 - 1200 MPa (High strength-to-weight ratio) | 500 - 1000 MPa (Good strength) |

| Corrosion Resistance | Excellent (Resistant to seawater, acids) | Good (Resistant to oxidation, acids) |

| Temperature Resistance | Up to 600degC (Stable at high temp.) | Up to 870degC (Better high-temp stability) |

| Cost | Higher (Expensive extraction and processing) | Lower (More economical) |

| Applications | Aerospace, Medical implants, Marine | Construction, Automotive, Kitchenware |

Introduction to Titanium Alloys and Stainless Steel Alloys

Titanium alloys offer superior strength-to-weight ratios and excellent corrosion resistance, making them ideal for aerospace, medical implants, and marine applications. Stainless steel alloys, characterized by their chromium content, provide outstanding durability, corrosion resistance, and ease of fabrication, commonly used in construction, automotive, and food processing industries. Both alloys present unique advantages depending on the specific performance requirements and environmental conditions of the application.

Chemical Composition Differences

Titanium alloys primarily consist of titanium combined with elements such as aluminum, vanadium, and molybdenum, which enhance strength and corrosion resistance while maintaining low density. Stainless steel alloys contain iron as the base element with significant amounts of chromium, nickel, and sometimes molybdenum, providing excellent corrosion resistance and mechanical properties. The distinct chemical composition of titanium alloys results in superior strength-to-weight ratios, whereas stainless steel alloys exhibit higher hardness and durability in demanding environments.

Mechanical Strength and Durability Comparison

Titanium alloys exhibit superior mechanical strength-to-weight ratios compared to stainless steel alloys, enhancing performance in aerospace and medical applications where weight reduction is critical. The durability of titanium alloys surpasses stainless steel, offering exceptional corrosion resistance and fatigue life in extreme environments. Stainless steel alloys provide high strength and excellent toughness but generally have higher density and lower corrosion resistance relative to titanium alloys, making them more suitable for structural applications requiring cost-effectiveness.

Weight and Density Considerations

Titanium alloys have a density of approximately 4.5 g/cm3, significantly lower than stainless steel alloys which range from 7.7 to 8.0 g/cm3, making titanium alloys about 40% lighter. This weight difference enhances applications in aerospace and automotive industries where reducing mass is critical for performance and fuel efficiency. The lower density of titanium alloys also contributes to improved strength-to-weight ratios compared to stainless steel alloys, enabling lighter yet durable components.

Corrosion Resistance: Titanium vs Stainless Steel

Titanium alloys exhibit superior corrosion resistance compared to stainless steel alloys, especially in aggressive environments like seawater, chlorides, and acidic or oxidizing conditions. The naturally forming titanium oxide film provides exceptional protection against pitting, crevice corrosion, and stress corrosion cracking, outperforming even the most corrosion-resistant grades of stainless steel such as 316L and 904L. This makes titanium alloys the preferred choice in aerospace, chemical processing, and marine applications where durability and longevity in corrosive environments are critical.

Biocompatibility and Medical Applications

Titanium alloys exhibit superior biocompatibility compared to stainless steel alloys due to their excellent corrosion resistance and lower cytotoxicity, making them ideal for medical implants and prosthetics. The oxide layer on titanium alloys promotes osseointegration, which enhances the stability of bone-implant interfaces in orthopedic and dental applications. Stainless steel alloys, while widely used for surgical instruments and temporary implants, often pose higher risks of allergic reactions and metal ion release.

Heat Resistance and High-Temperature Performance

Titanium alloys exhibit superior heat resistance compared to stainless steel alloys, maintaining structural integrity at temperatures up to 600degC, whereas stainless steels typically withstand up to 400-500degC. The high-temperature performance of titanium alloys is enhanced by their low density and excellent oxidation resistance, making them ideal for aerospace and automotive applications requiring lightweight materials under thermal stress. Stainless steel alloys offer good heat resistance but are generally heavier and prone to scaling at elevated temperatures, limiting their use in extreme thermal environments.

Manufacturing Processes and Machinability

Titanium alloys offer superior strength-to-weight ratios and corrosion resistance but require specialized manufacturing processes such as vacuum arc remelting and precision forging due to their reactivity at high temperatures. Stainless steel alloys, benefiting from established methods like hot rolling and conventional machining, provide easier machinability with less tool wear and higher cutting speeds. While titanium alloys demand slower machining with coated carbide tools under stringent cooling conditions, stainless steel alloys enable faster production cycles with less complex tooling.

Cost Analysis: Titanium Alloys vs Stainless Steel

Titanium alloys typically have higher upfront material costs compared to stainless steel alloys due to their complex extraction and processing methods. Despite the initial expense, titanium alloys offer superior strength-to-weight ratios and corrosion resistance, potentially reducing long-term maintenance and replacement costs. Stainless steel alloys remain a cost-effective choice for applications where budget constraints outweigh the need for titanium's advanced performance characteristics.

Application Suitability in Key Industries

Titanium alloys exhibit superior corrosion resistance and high strength-to-weight ratios, making them ideal for aerospace, medical implants, and marine applications where weight reduction and durability are critical. Stainless steel alloys offer excellent toughness, cost-effectiveness, and resistance to high temperatures, favoring their use in construction, automotive, and food processing industries. The choice between titanium and stainless steel alloys depends heavily on specific performance requirements, environmental conditions, and economic considerations in the targeted industry.

Titanium alloys vs Stainless steel alloys Infographic

materialdif.com

materialdif.com