Superalloys outperform base alloys by offering exceptional high-temperature strength, corrosion resistance, and oxidation stability, making them ideal for aerospace and power generation applications. While base alloys serve well in standard environments, superalloys maintain mechanical integrity under extreme thermal and mechanical stress. The advanced composition of superalloys, often enriched with elements like nickel, cobalt, and chromium, enhances their durability compared to typical base alloys.

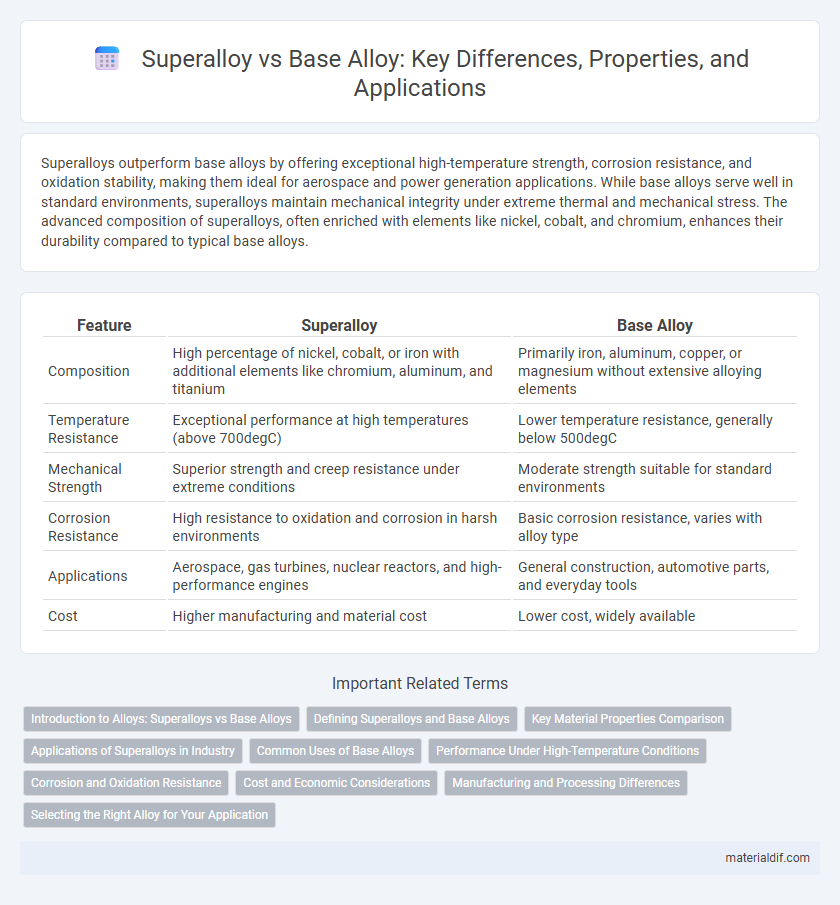

Table of Comparison

| Feature | Superalloy | Base Alloy |

|---|---|---|

| Composition | High percentage of nickel, cobalt, or iron with additional elements like chromium, aluminum, and titanium | Primarily iron, aluminum, copper, or magnesium without extensive alloying elements |

| Temperature Resistance | Exceptional performance at high temperatures (above 700degC) | Lower temperature resistance, generally below 500degC |

| Mechanical Strength | Superior strength and creep resistance under extreme conditions | Moderate strength suitable for standard environments |

| Corrosion Resistance | High resistance to oxidation and corrosion in harsh environments | Basic corrosion resistance, varies with alloy type |

| Applications | Aerospace, gas turbines, nuclear reactors, and high-performance engines | General construction, automotive parts, and everyday tools |

| Cost | Higher manufacturing and material cost | Lower cost, widely available |

Introduction to Alloys: Superalloys vs Base Alloys

Superalloys exhibit exceptional mechanical strength, corrosion resistance, and high-temperature stability compared to base alloys, making them essential for aerospace and power generation applications. Base alloys, typically simpler in composition such as iron or aluminum-based, provide foundational properties like malleability and conductivity but lack the advanced performance characteristics of superalloys. The microstructural design of superalloys, often containing elements like nickel, cobalt, and chromium, significantly enhances durability in extreme environments where base alloys would fail.

Defining Superalloys and Base Alloys

Superalloys are advanced metallic materials designed to withstand extreme environments, exhibiting exceptional mechanical strength, resistance to thermal creep deformation, and oxidation at high temperatures. Base alloys, by contrast, serve as fundamental metallic compositions that provide essential mechanical properties and form the backbone for further alloy development. The distinction lies in superalloys' specialized enhancements--usually via elements like nickel, cobalt, or iron--offering superior performance in aerospace, power generation, and industrial applications compared to more generalized base alloys.

Key Material Properties Comparison

Superalloys exhibit superior mechanical strength, corrosion resistance, and high-temperature stability compared to base alloys, making them ideal for demanding aerospace and power generation applications. Base alloys typically offer lower cost and ease of fabrication but lack the enhanced creep resistance and oxidation tolerance characteristic of superalloys. Key material properties such as tensile strength, melting point, and thermal fatigue resistance significantly favor superalloys, ensuring performance in extreme environments.

Applications of Superalloys in Industry

Superalloys exhibit exceptional strength and corrosion resistance at high temperatures, making them ideal for aerospace turbine engines, nuclear reactors, and gas turbines. Their ability to maintain mechanical integrity under extreme thermal and oxidative stress outperforms base alloys in critical components like jet engine blades and combustion chambers. Industries rely on superalloys for enhanced durability and efficiency in high-performance environments where standard base alloys would fail.

Common Uses of Base Alloys

Base alloys are commonly used in automotive components, structural applications, and general engineering due to their cost-effectiveness and adequate mechanical properties. They provide essential strength and corrosion resistance for everyday environments, making them ideal for manufacturing engine parts, fasteners, and piping systems. Unlike superalloys, base alloys are favored for applications where extreme heat and stress resistance are not critical.

Performance Under High-Temperature Conditions

Superalloys exhibit exceptional performance under high-temperature conditions due to their enhanced composition, including elements like nickel, cobalt, and chromium, which provide superior oxidation and creep resistance. Base alloys, in contrast, often lack the critical microstructural stability required for extreme environments, leading to reduced mechanical strength and increased degradation. The advanced alloying elements and controlled grain structures in superalloys enable sustained durability and efficiency in aerospace and power generation applications where temperatures exceed 700degC.

Corrosion and Oxidation Resistance

Superalloys exhibit superior corrosion and oxidation resistance compared to base alloys due to their high concentrations of chromium, nickel, and aluminum, which form stable oxide layers that protect the material from environmental degradation. Base alloys, typically composed of simpler metal matrices like iron or aluminum, lack these protective oxide films and therefore experience accelerated corrosion and oxidation in harsh conditions. The advanced microstructure and alloying elements in superalloys significantly enhance their performance in high-temperature and chemically aggressive environments.

Cost and Economic Considerations

Superalloys exhibit superior performance under extreme temperatures and corrosion, justifying their higher cost compared to base alloys commonly used in less demanding applications. The production and raw material expenses for superalloys significantly impact overall project budgets, demanding careful economic evaluation for high-performance sectors like aerospace. Base alloys provide cost-effective solutions where thermal and mechanical stresses are moderate, enabling wider accessibility in industrial manufacturing with lower material and processing costs.

Manufacturing and Processing Differences

Superalloys typically require more complex manufacturing processes such as vacuum induction melting and directional solidification to achieve their high-performance characteristics, while base alloys use simpler casting or forging techniques. The processing of superalloys often involves precise heat treatments to optimize their microstructure for enhanced strength and corrosion resistance at high temperatures. Base alloys, in contrast, undergo standard annealing and tempering processes, reflecting their less demanding service environments.

Selecting the Right Alloy for Your Application

Superalloys offer superior mechanical strength, corrosion resistance, and high-temperature stability compared to base alloys, making them ideal for aerospace, power generation, and chemical processing applications. Base alloys, while more cost-effective and easier to machine, may lack the durability required for extreme environments. Selecting the right alloy involves evaluating operational conditions, such as temperature limits, environmental exposure, and mechanical loads, to balance performance and cost-effectiveness.

Superalloy vs Base alloy Infographic

materialdif.com

materialdif.com