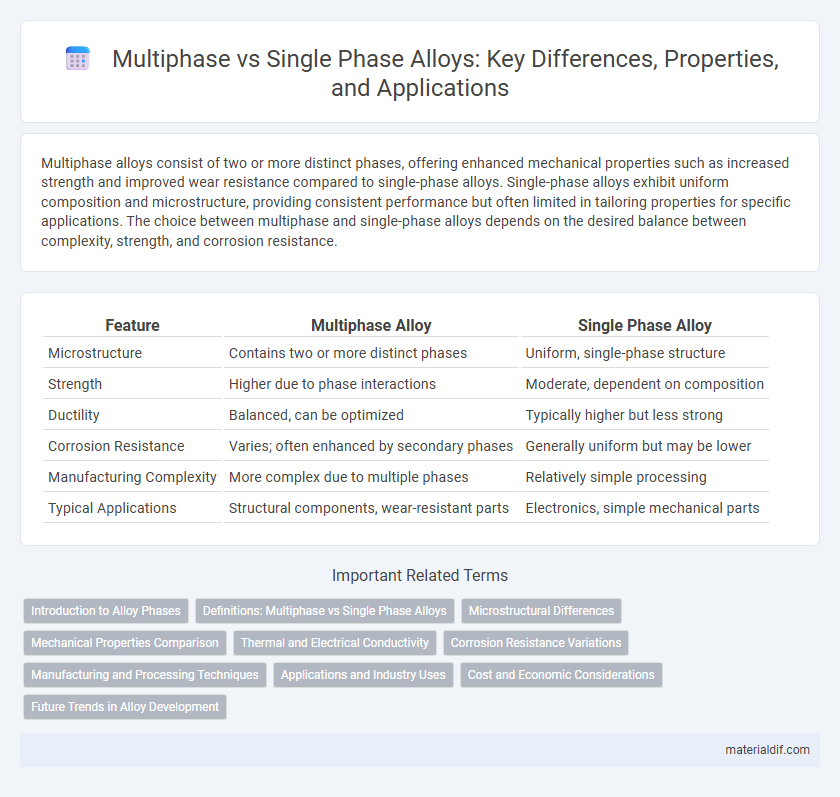

Multiphase alloys consist of two or more distinct phases, offering enhanced mechanical properties such as increased strength and improved wear resistance compared to single-phase alloys. Single-phase alloys exhibit uniform composition and microstructure, providing consistent performance but often limited in tailoring properties for specific applications. The choice between multiphase and single-phase alloys depends on the desired balance between complexity, strength, and corrosion resistance.

Table of Comparison

| Feature | Multiphase Alloy | Single Phase Alloy |

|---|---|---|

| Microstructure | Contains two or more distinct phases | Uniform, single-phase structure |

| Strength | Higher due to phase interactions | Moderate, dependent on composition |

| Ductility | Balanced, can be optimized | Typically higher but less strong |

| Corrosion Resistance | Varies; often enhanced by secondary phases | Generally uniform but may be lower |

| Manufacturing Complexity | More complex due to multiple phases | Relatively simple processing |

| Typical Applications | Structural components, wear-resistant parts | Electronics, simple mechanical parts |

Introduction to Alloy Phases

Multiphase alloys consist of two or more distinct phases with different microstructures, enhancing mechanical properties such as strength and corrosion resistance compared to single-phase alloys, which contain a uniform microstructure. The coexistence of multiple phases, often achieved through controlled cooling or heat treatment, allows for tailored performance in demanding applications like aerospace and automotive industries. Understanding the phase composition and distribution is critical for optimizing alloy behavior and achieving desired material characteristics.

Definitions: Multiphase vs Single Phase Alloys

Multiphase alloys consist of two or more distinct phases, each with different microstructures and properties, which enhance mechanical performance and corrosion resistance. Single phase alloys are composed of a uniform microstructure with one homogenous phase, resulting in consistent but often less versatile material properties. The interaction between phases in multiphase alloys allows for tailored characteristics that single phase alloys cannot achieve.

Microstructural Differences

Multiphase alloys exhibit distinct microstructural regions composed of two or more phases, each with unique compositions and crystal structures, enhancing mechanical properties such as strength and toughness through phase interactions. Single phase alloys consist of a uniform microstructure with a single crystal structure, resulting in more homogeneous properties but typically lower strength compared to multiphase counterparts. The presence of multiple phases in multiphase alloys creates complex grain boundaries and interfaces that influence diffusion, corrosion resistance, and deformation mechanisms.

Mechanical Properties Comparison

Multiphase alloys exhibit enhanced mechanical properties such as increased strength, toughness, and fatigue resistance compared to single phase alloys due to the presence of multiple distinct phases that hinder dislocation motion. The interfaces between phases act as barriers to crack propagation, improving durability under cyclic loading conditions. Single phase alloys generally offer uniform mechanical behavior but lack the complex microstructural reinforcement found in multiphase systems, limiting their performance under high-stress environments.

Thermal and Electrical Conductivity

Multiphase alloys typically exhibit lower thermal and electrical conductivity compared to single phase alloys due to scattering at phase boundaries disrupting electron and phonon transport. Single phase alloys provide more uniform atomic structures, enabling higher conductivity as electrons and heat flow more freely. The presence of multiple phases introduces interfaces that act as barriers, reducing overall conductivity efficiency in multiphase materials.

Corrosion Resistance Variations

Multiphase alloys exhibit enhanced corrosion resistance due to the presence of distinct phases that can form protective oxide layers, reducing overall material degradation in aggressive environments. Single phase alloys, while more homogeneous, often lack the microstructural complexity needed to inhibit localized corrosion effectively. Variations in corrosion resistance between multiphase and single phase alloys are largely influenced by their phase distribution, chemical composition, and the stability of passivating films formed on their surfaces.

Manufacturing and Processing Techniques

Multiphase alloys require complex manufacturing techniques such as controlled solidification, heat treatment, and phase transformation to achieve desired microstructures, enhancing mechanical properties and corrosion resistance. Single phase alloys typically undergo simpler processing methods like casting and annealing, which result in uniform composition but limited property customization. Advanced methods like powder metallurgy and additive manufacturing offer precise control in multiphase alloy fabrication, optimizing performance for aerospace and automotive applications.

Applications and Industry Uses

Multiphase alloys are favored in aerospace and automotive industries for their superior strength, wear resistance, and thermal stability compared to single phase alloys, making them ideal for engine components and structural parts. Single phase alloys find extensive use in electronics and consumer goods, where uniformity, corrosion resistance, and ease of fabrication are critical. The choice between multiphase and single phase alloys hinges on application-specific performance requirements such as mechanical durability, thermal conductivity, and environmental exposure.

Cost and Economic Considerations

Multiphase alloys generally involve higher raw material and processing costs due to complex microstructural engineering and multiple constituent phases, increasing fabrication expenses compared to single phase alloys. Single phase alloys typically offer more straightforward manufacturing processes, reducing production cost and economic burden, especially in large-scale applications. Economic considerations favor single phase alloys where cost-efficiency and scalability are critical, while multiphase alloys justify their expense through enhanced mechanical properties for specialized, high-performance uses.

Future Trends in Alloy Development

Future trends in alloy development emphasize the advancement of multiphase alloys due to their superior mechanical properties, including enhanced strength, toughness, and corrosion resistance, compared to traditional single phase alloys. Innovations in additive manufacturing and computational materials science enable precise control over phase distribution, optimizing performance for aerospace, automotive, and biomedical applications. The integration of machine learning models accelerates the discovery of multiphase compositions, promoting alloy designs that meet stringent demands for sustainability and lightweight durability.

Multiphase Alloy vs Single Phase Alloy Infographic

materialdif.com

materialdif.com