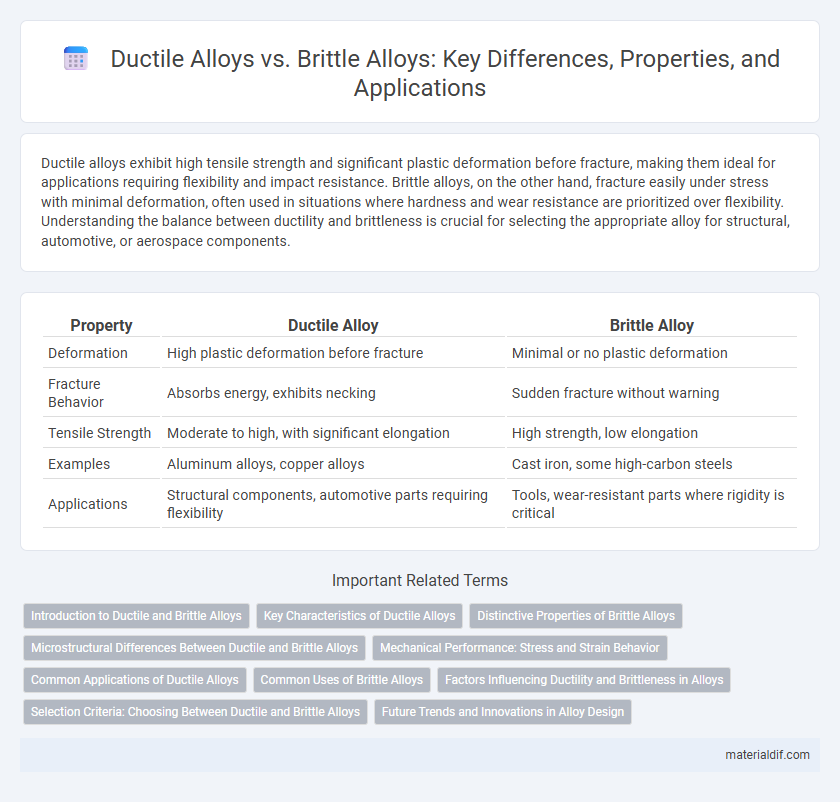

Ductile alloys exhibit high tensile strength and significant plastic deformation before fracture, making them ideal for applications requiring flexibility and impact resistance. Brittle alloys, on the other hand, fracture easily under stress with minimal deformation, often used in situations where hardness and wear resistance are prioritized over flexibility. Understanding the balance between ductility and brittleness is crucial for selecting the appropriate alloy for structural, automotive, or aerospace components.

Table of Comparison

| Property | Ductile Alloy | Brittle Alloy |

|---|---|---|

| Deformation | High plastic deformation before fracture | Minimal or no plastic deformation |

| Fracture Behavior | Absorbs energy, exhibits necking | Sudden fracture without warning |

| Tensile Strength | Moderate to high, with significant elongation | High strength, low elongation |

| Examples | Aluminum alloys, copper alloys | Cast iron, some high-carbon steels |

| Applications | Structural components, automotive parts requiring flexibility | Tools, wear-resistant parts where rigidity is critical |

Introduction to Ductile and Brittle Alloys

Ductile alloys exhibit significant plastic deformation before fracture, characterized by their ability to absorb energy and undergo extensive shape changes without cracking. Brittle alloys, in contrast, fracture with minimal plastic deformation, often resulting in sudden failure due to their limited toughness. Understanding the atomic structure and bonding in ductile and brittle alloys is essential for optimizing mechanical performance in aerospace, automotive, and structural applications.

Key Characteristics of Ductile Alloys

Ductile alloys exhibit high tensile strength and significant plastic deformation before fracture, making them ideal for applications requiring flexibility and resistance to cracking. These alloys, such as aluminum and copper-based materials, demonstrate substantial elongation and energy absorption under stress. Their microstructure typically features a more uniform grain pattern, enhancing toughness and reducing brittleness compared to brittle alloys like cast iron or certain high-carbon steels.

Distinctive Properties of Brittle Alloys

Brittle alloys exhibit low ductility and fracture easily under stress, characterized by limited plastic deformation before failure. These alloys often have a high hardness and tensile strength but are prone to sudden, catastrophic cracking due to their inherent atomic structure. Common examples include cast iron and certain high-carbon steels, which display distinctive brittleness compared to more malleable, ductile alloys.

Microstructural Differences Between Ductile and Brittle Alloys

Ductile alloys exhibit a microstructure characterized by evenly distributed, fine-grained phases and a high density of dislocations that promote plastic deformation. Brittle alloys typically contain coarse, intergranular phases and precipitates that act as crack initiation sites, limiting their ability to deform plastically. Grain boundary strengthening and the presence of ductile phase inclusions significantly influence the toughness and failure mechanisms in these alloys.

Mechanical Performance: Stress and Strain Behavior

Ductile alloys exhibit significant plastic deformation under stress, characterized by a high strain before fracture, which allows them to absorb substantial energy and deform without sudden failure. Brittle alloys, in contrast, demonstrate limited strain capacity and fail abruptly when the stress exceeds their elastic limit, resulting in minimal plastic deformation. The stress-strain curve of ductile alloys shows a pronounced yield point and a large area under the curve, indicating superior toughness compared to the steep, linear curve of brittle alloys.

Common Applications of Ductile Alloys

Ductile alloys are widely used in automotive components, aerospace structures, and electrical connectors due to their high tensile strength and ability to deform without fracturing. Their excellent malleability and toughness make them ideal for manufacturing pipes, gears, and fasteners that require resistance to impact and fatigue. Common examples include aluminum, copper, and certain steel alloys that balance ductility with durability for critical industrial applications.

Common Uses of Brittle Alloys

Brittle alloys are commonly used in applications requiring high hardness and wear resistance, such as cutting tools, abrasives, and ballistic armor. These alloys are essential in aerospace components and electrical contacts where dimensional stability and resistance to deformation under stress are critical. Their inability to undergo significant plastic deformation makes them ideal for precise, rigid parts subjected to minimal impact.

Factors Influencing Ductility and Brittleness in Alloys

Ductility in alloys is primarily influenced by factors such as grain size, temperature, and alloy composition, with finer grains and elevated temperatures generally enhancing ductility by facilitating dislocation movement. Brittleness is often caused by the presence of intermetallic compounds, impurity elements, and low temperatures, which restrict plastic deformation and promote crack initiation. The balance between ductile and brittle behavior depends on controlling microstructural features like phase distribution and defect density through processing techniques such as heat treatment and alloying element adjustment.

Selection Criteria: Choosing Between Ductile and Brittle Alloys

Selecting between ductile and brittle alloys depends primarily on the application's mechanical stress requirements and environmental conditions. Ductile alloys, characterized by high tensile strength and significant elongation before fracture, are preferred in applications requiring energy absorption and resistance to impact or deformation. Brittle alloys, exhibiting minimal plastic deformation and higher hardness, are suitable for components demanding wear resistance and dimensional stability under compressive loads.

Future Trends and Innovations in Alloy Design

Future trends in alloy design emphasize enhancing ductility through nanoscale grain refinement and additive manufacturing techniques, enabling alloys with superior toughness and formability. Innovations such as high-entropy alloys (HEAs) and compositionally complex alloys (CCAs) offer promising pathways to tailor mechanical properties, balancing ductility and brittleness for advanced structural applications. Emerging computational materials science and machine learning accelerate the discovery of ductile alloys with optimized microstructures, driving next-generation performance in aerospace, automotive, and energy sectors.

Ductile Alloy vs Brittle Alloy Infographic

materialdif.com

materialdif.com