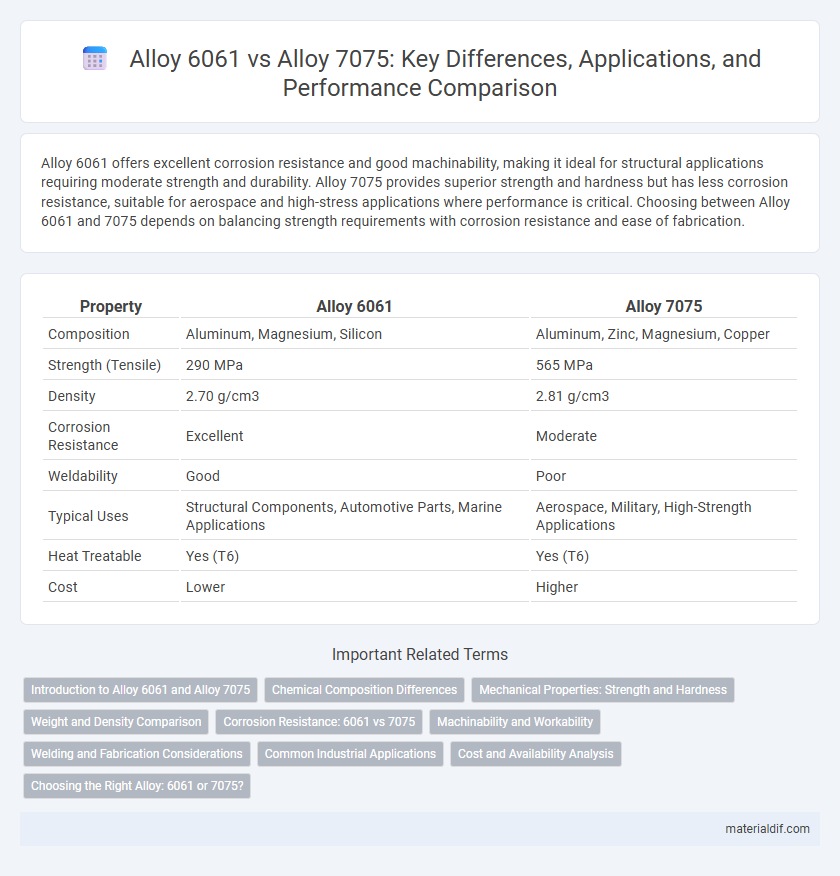

Alloy 6061 offers excellent corrosion resistance and good machinability, making it ideal for structural applications requiring moderate strength and durability. Alloy 7075 provides superior strength and hardness but has less corrosion resistance, suitable for aerospace and high-stress applications where performance is critical. Choosing between Alloy 6061 and 7075 depends on balancing strength requirements with corrosion resistance and ease of fabrication.

Table of Comparison

| Property | Alloy 6061 | Alloy 7075 |

|---|---|---|

| Composition | Aluminum, Magnesium, Silicon | Aluminum, Zinc, Magnesium, Copper |

| Strength (Tensile) | 290 MPa | 565 MPa |

| Density | 2.70 g/cm3 | 2.81 g/cm3 |

| Corrosion Resistance | Excellent | Moderate |

| Weldability | Good | Poor |

| Typical Uses | Structural Components, Automotive Parts, Marine Applications | Aerospace, Military, High-Strength Applications |

| Heat Treatable | Yes (T6) | Yes (T6) |

| Cost | Lower | Higher |

Introduction to Alloy 6061 and Alloy 7075

Alloy 6061 is a versatile aluminum alloy known for its excellent corrosion resistance, good mechanical properties, and weldability, making it ideal for structural applications. Alloy 7075 offers superior strength and hardness due to its high zinc content, commonly used in aerospace and high-stress engineering components. The primary distinction lies in Alloy 6061's balance of strength and corrosion resistance versus Alloy 7075's focus on maximum strength and fatigue resistance.

Chemical Composition Differences

Alloy 6061 features a primary composition of magnesium (0.8-1.2%) and silicon (0.4-0.8%), providing moderate strength and excellent corrosion resistance. Alloy 7075 contains higher zinc content (5.1-6.1%) along with magnesium (2.1-2.9%) and copper (1.2-2.0%), resulting in significantly increased tensile strength but reduced corrosion resistance compared to 6061. The presence of zinc as the main alloying element in 7075 defines its superior mechanical properties, while 6061's balance of magnesium and silicon enhances weldability and versatility.

Mechanical Properties: Strength and Hardness

Alloy 7075 exhibits superior tensile strength (around 570 MPa) and higher hardness (Rockwell B85) compared to Alloy 6061, which typically has a tensile strength of approximately 310 MPa and hardness near Rockwell B70. The enhanced strength and hardness of 7075 make it suitable for high-stress applications such as aerospace and military components, whereas 6061 offers better corrosion resistance and weldability for structural uses. Mechanical property differences result from 7075's zinc as its primary alloying element versus 6061's magnesium and silicon composition.

Weight and Density Comparison

Alloy 6061 has a density of approximately 2.70 g/cm3, making it moderately lightweight and suitable for applications requiring a balance of strength and weight. Alloy 7075 is slightly denser, with a density around 2.81 g/cm3, contributing to its higher strength-to-weight ratio ideal for aerospace and high-performance uses. The marginal difference in weight impacts material selection where both durability and lightweight properties are critical.

Corrosion Resistance: 6061 vs 7075

Alloy 6061 exhibits superior corrosion resistance compared to Alloy 7075, making it more suitable for marine and outdoor applications. The presence of magnesium and silicon in 6061 enhances its oxide layer, providing better protection against oxidation and environmental damage. Conversely, Alloy 7075, despite its higher strength, is more prone to stress corrosion cracking and requires additional protective coatings in corrosive environments.

Machinability and Workability

Alloy 6061 offers superior machinability due to its excellent machinable properties, resulting in smoother cutting and less tool wear compared to Alloy 7075. In contrast, Alloy 7075 has lower machinability but provides higher strength, making it more challenging to machine but better suited for high-stress applications. Workability in Alloy 6061 is generally better because of its good forming and welding characteristics, whereas Alloy 7075 is less workable and more prone to cracking during forming processes.

Welding and Fabrication Considerations

Alloy 6061 offers superior weldability and is commonly used in applications requiring extensive welding, thanks to its excellent corrosion resistance and ease of fabrication. Alloy 7075, while stronger, presents challenges in welding due to its susceptibility to cracking and reduced corrosion resistance post-welding, making it less suitable for welded structures. Choosing Alloy 6061 enhances fabrication efficiency and structural integrity when welding is a critical process.

Common Industrial Applications

Alloy 6061 is widely used in structural applications such as aerospace components, automotive parts, and marine fittings due to its excellent corrosion resistance and good weldability. Alloy 7075 is preferred for high-stress applications like aircraft structures, military equipment, and sports gear because of its superior strength and fatigue resistance. Both alloys are essential in manufacturing but are selected based on specific performance requirements in industrial settings.

Cost and Availability Analysis

Alloy 6061 is generally more cost-effective and widely available compared to Alloy 7075, making it a preferred choice for budget-sensitive projects. The higher price of Alloy 7075 reflects its superior strength and performance characteristics, which are often critical in aerospace and high-stress applications. Supply chain stability favors Alloy 6061 due to its extensive commercial use and production scale, ensuring consistent availability.

Choosing the Right Alloy: 6061 or 7075?

Alloy 6061 offers excellent corrosion resistance and good machinability, making it ideal for structural applications requiring moderate strength and weldability. Alloy 7075 features superior tensile strength and fatigue resistance, suited for aerospace and high-stress components where performance is critical. Selecting between 6061 and 7075 depends on balancing strength requirements, corrosion resistance, and fabrication methods for the specific project.

Alloy 6061 vs Alloy 7075 Infographic

materialdif.com

materialdif.com