Cupronickel and cupro-nickel both refer to the same metal alloy primarily composed of copper and nickel but may differ in spelling based on regional usage or industry preference. This alloy is known for its excellent corrosion resistance and antimicrobial properties, making it ideal for applications requiring durability and hygiene, such as in healthcare or marine environments. Choosing either term depends on context, but their chemical composition and benefits remain identical, ensuring consistent performance in various products.

Table of Comparison

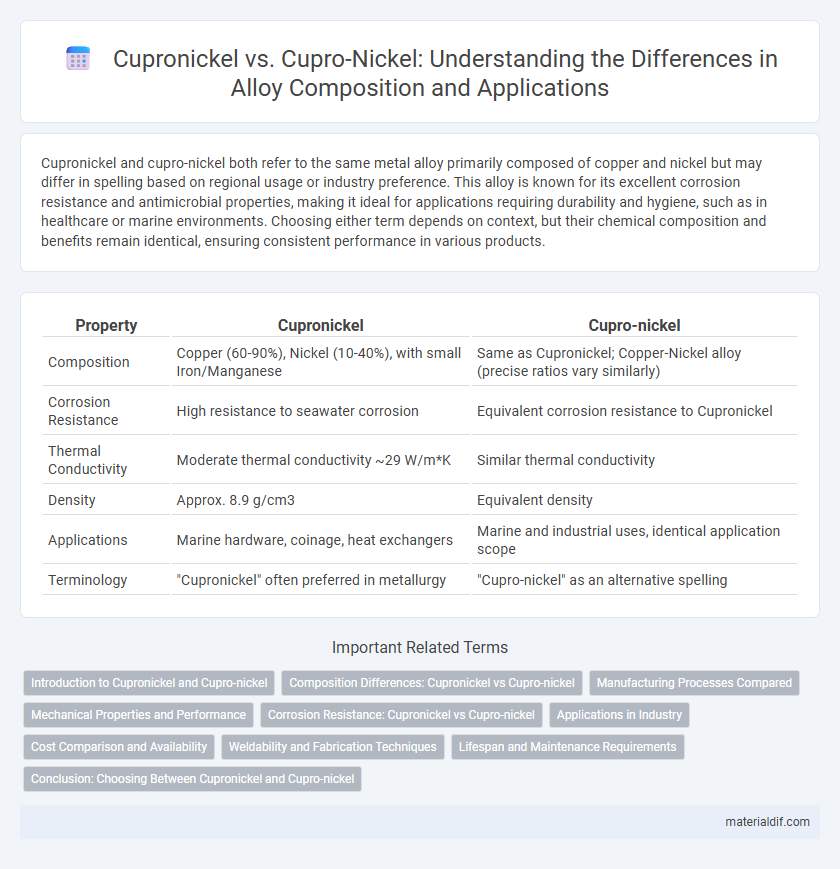

| Property | Cupronickel | Cupro-nickel |

|---|---|---|

| Composition | Copper (60-90%), Nickel (10-40%), with small Iron/Manganese | Same as Cupronickel; Copper-Nickel alloy (precise ratios vary similarly) |

| Corrosion Resistance | High resistance to seawater corrosion | Equivalent corrosion resistance to Cupronickel |

| Thermal Conductivity | Moderate thermal conductivity ~29 W/m*K | Similar thermal conductivity |

| Density | Approx. 8.9 g/cm3 | Equivalent density |

| Applications | Marine hardware, coinage, heat exchangers | Marine and industrial uses, identical application scope |

| Terminology | "Cupronickel" often preferred in metallurgy | "Cupro-nickel" as an alternative spelling |

Introduction to Cupronickel and Cupro-nickel

Cupronickel and cupro-nickel are copper-based alloys primarily composed of copper and nickel with varying amounts of other elements like iron and manganese to enhance corrosion resistance and strength. Commonly used in marine engineering and coinage, cupronickel offers excellent resistance to seawater corrosion and biofouling due to its high nickel content, typically ranging between 10-30%. The term cupro-nickel is an alternative spelling, but both physically and chemically refer to the same alloy with applications in desalination plants, heat exchangers, and gas turbines.

Composition Differences: Cupronickel vs Cupro-nickel

Cupronickel typically consists of 75% copper and 25% nickel, sometimes with trace amounts of iron and manganese, offering excellent corrosion resistance and thermal conductivity. Cupro-nickel, although a variant spelling, often denotes similar alloys but can emphasize slight variations in composition ratios tailored for specific applications like marine environments or coinage. The key composition difference lies in the precise nickel and copper balance, influencing mechanical strength, corrosion resistance, and fabrication properties.

Manufacturing Processes Compared

Cupronickel and cupro-nickel alloys share similar compositions but differ in naming conventions, which can impact sourcing and specification clarity in manufacturing processes. Both alloys undergo processes such as melting, casting, and hot rolling to achieve desired mechanical properties, but precise control of cooling rates and alloying elements is critical to prevent phase segregation and ensure corrosion resistance. Advanced manufacturing techniques like vacuum induction melting enhance material purity and consistency in both cupronickel variants, optimizing their performance in marine and coinage applications.

Mechanical Properties and Performance

Cupronickel and cupro-nickel alloys exhibit excellent corrosion resistance and mechanical strength, making them ideal for marine and heat exchanger applications. Typically, these alloys provide high tensile strength ranging from 400 to 600 MPa and superior ductility, enabling them to withstand cyclic stresses and thermal expansion effectively. The microstructure of cupronickel enhances its toughness and fatigue resistance, outperforming many conventional copper alloys under harsh environmental conditions.

Corrosion Resistance: Cupronickel vs Cupro-nickel

Cupronickel and cupro-nickel alloys both exhibit exceptional corrosion resistance, particularly in marine environments due to their high copper and nickel content. The corrosion resistance performance mainly depends on the precise composition, with typical cupronickel containing 70% copper and 30% nickel, providing excellent resistance against seawater, biofouling, and erosion. Both terms describe the same alloy type, and there is no difference in corrosion resistance between "cupronickel" and "cupro-nickel.

Applications in Industry

Cupronickel and cupro-nickel alloys are widely used in marine engineering, desalination plants, and coinage due to their excellent corrosion resistance and thermal conductivity. Cupronickel typically contains 10-30% nickel with the remainder copper, providing optimal strength and anti-fouling properties for seawater components. Industries leverage these alloys for heat exchangers, aerospace parts, and electrical connectors, benefiting from their durability and resistance to biofouling.

Cost Comparison and Availability

Cupronickel and Cupro-nickel refer to the same copper-nickel alloy, with "Cupronickel" being the more widely accepted spelling in industrial standards. The cost of cupronickel typically fluctuates based on the market prices of copper and nickel, but both terms denote the identical alloy composition, so there is no inherent cost difference between them. Availability remains consistent globally under both names, with established supply chains ensuring steady access for manufacturing and marine applications.

Weldability and Fabrication Techniques

Cupronickel and cupro-nickel refer to the same copper-nickel alloy known for excellent corrosion resistance and thermal conductivity. This alloy exhibits good weldability using methods such as TIG, MIG, and resistance welding, producing strong, corrosion-resistant joints suitable for marine and industrial applications. Fabrication techniques commonly include cold working, machining, and annealing, which enhance strength and flexibility while maintaining the alloy's structural integrity.

Lifespan and Maintenance Requirements

Cupronickel alloys offer excellent corrosion resistance and durability, resulting in a longer lifespan with minimal maintenance in marine and industrial environments. The term Cupro-nickel, though used interchangeably, typically refers to the same alloy family known for strong biofouling resistance and low maintenance needs. Proper alloy selection and routine inspections further extend the operational life of cupronickel components by preventing corrosion and wear.

Conclusion: Choosing Between Cupronickel and Cupro-nickel

Cupronickel and cupro-nickel refer to the same corrosion-resistant copper-nickel alloy used in marine and industrial applications. Selecting between the terms depends on regional spelling preferences rather than material differences, as both denote alloys containing typically 10-30% nickel with excellent resistance to seawater corrosion. Understanding this equivalence ensures accurate specification in procurement and technical documentation without confusion.

Cupronickel vs Cupro-nickel Infographic

materialdif.com

materialdif.com