Nickel-Chromium alloys offer superior corrosion resistance and high-temperature strength compared to Nickel-Copper alloys, making them ideal for industrial applications requiring durability under extreme conditions. Nickel-Copper alloys feature excellent resistance to seawater corrosion and biofouling, which is essential for marine environments and piping systems. Selecting between these alloys depends on the specific environmental exposure and mechanical requirements of the application.

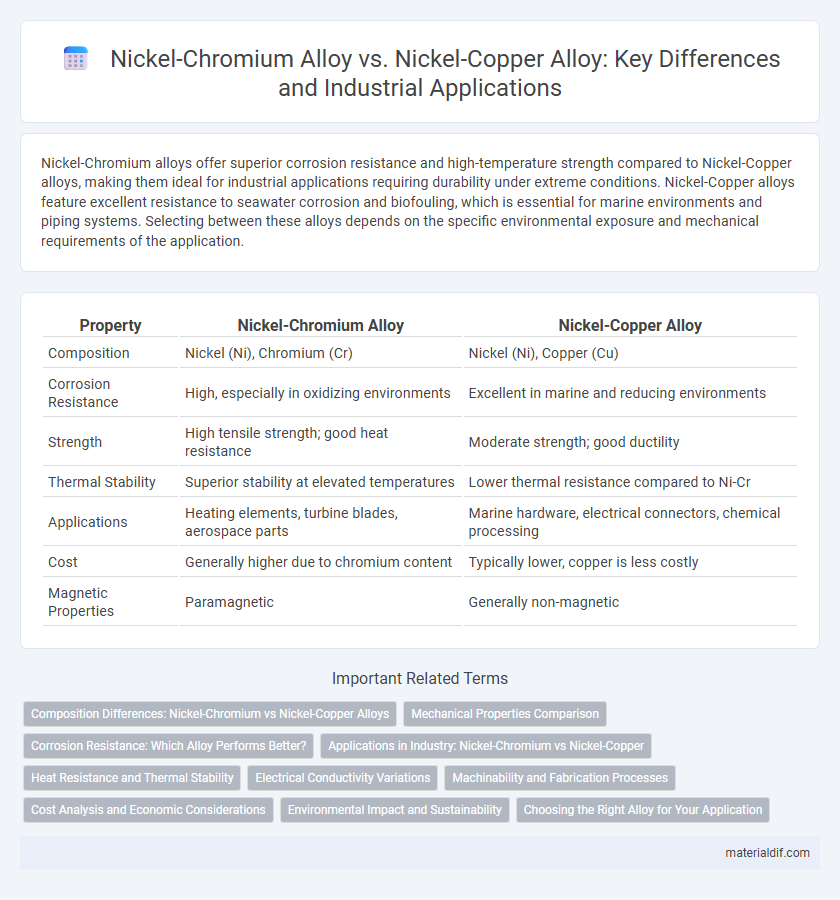

Table of Comparison

| Property | Nickel-Chromium Alloy | Nickel-Copper Alloy |

|---|---|---|

| Composition | Nickel (Ni), Chromium (Cr) | Nickel (Ni), Copper (Cu) |

| Corrosion Resistance | High, especially in oxidizing environments | Excellent in marine and reducing environments |

| Strength | High tensile strength; good heat resistance | Moderate strength; good ductility |

| Thermal Stability | Superior stability at elevated temperatures | Lower thermal resistance compared to Ni-Cr |

| Applications | Heating elements, turbine blades, aerospace parts | Marine hardware, electrical connectors, chemical processing |

| Cost | Generally higher due to chromium content | Typically lower, copper is less costly |

| Magnetic Properties | Paramagnetic | Generally non-magnetic |

Composition Differences: Nickel-Chromium vs Nickel-Copper Alloys

Nickel-chromium alloys typically contain 10-30% chromium, which enhances corrosion resistance and high-temperature strength, while nickel-copper alloys include 10-30% copper, providing excellent resistance to seawater and chemical environments. The chromium content in nickel-chromium alloys forms a passive oxide layer that protects against oxidation, whereas the copper in nickel-copper alloys improves conductivity and resistance to biofouling. These compositional differences drive their distinct industrial applications, with nickel-chromium favored in heating elements and turbines, and nickel-copper preferred for marine and chemical processing equipment.

Mechanical Properties Comparison

Nickel-chromium alloys exhibit superior high-temperature strength and oxidation resistance compared to nickel-copper alloys, making them ideal for applications requiring durability under thermal stress. Nickel-copper alloys typically offer enhanced corrosion resistance and better ductility at lower temperatures, beneficial for marine and chemical environments. Mechanical properties such as tensile strength and hardness are generally higher in nickel-chromium alloys, while nickel-copper alloys provide improved toughness and elongation.

Corrosion Resistance: Which Alloy Performs Better?

Nickel-chromium alloys exhibit superior corrosion resistance compared to nickel-copper alloys due to the formation of a stable, passive chromium oxide layer that protects against oxidation and chemical attack. Nickel-chromium alloys perform exceptionally well in harsh environments such as high-temperature and acidic conditions, making them ideal for industrial applications requiring long-term durability. In contrast, nickel-copper alloys offer good resistance to seawater corrosion but generally fall short under more aggressive chemical exposures where chromium's protective properties dominate.

Applications in Industry: Nickel-Chromium vs Nickel-Copper

Nickel-chromium alloys excel in high-temperature applications such as heating elements, turbine blades, and aerospace components due to their superior oxidation resistance and strength. Nickel-copper alloys are preferred in marine environments, chemical processing, and electrical resistors for their excellent corrosion resistance and thermal conductivity. Industrial performance differences highlight nickel-chromium's suitability for extreme heat and nickel-copper's advantage in corrosive or conductive contexts.

Heat Resistance and Thermal Stability

Nickel-chromium alloys exhibit superior heat resistance and thermal stability due to chromium's ability to form a protective oxide layer, preventing oxidation at high temperatures up to 1200degC. In contrast, nickel-copper alloys have lower heat resistance, typically up to 600degC, and are more prone to thermal degradation in oxidizing environments. These properties make nickel-chromium alloys ideal for applications like heating elements and turbine blades, whereas nickel-copper alloys suit corrosion-resistant components in moderate temperature ranges.

Electrical Conductivity Variations

Nickel-chromium alloys exhibit lower electrical conductivity, typically around 1-5% IACS (International Annealed Copper Standard), due to chromium's strong electron scattering effect. Nickel-copper alloys generally demonstrate higher conductivity, ranging from 15-25% IACS, benefiting from copper's excellent electrical properties. These variations significantly influence the selection of alloys for applications requiring precise electrical resistance and thermal stability.

Machinability and Fabrication Processes

Nickel-chromium alloys exhibit excellent machinability due to their balanced hardness and strength, making them suitable for precision fabrication processes such as CNC machining and electrochemical machining. In contrast, nickel-copper alloys offer superior ductility and corrosion resistance, which enhances their performance in complex forming and welding operations but may require slower cutting speeds to prevent tool wear. Both alloys demand tailored machining parameters to optimize tool life and surface finish, with nickel-chromium alloys favoring higher cutting speeds and nickel-copper alloys benefiting from lubricated cutting environments during fabrication.

Cost Analysis and Economic Considerations

Nickel-chromium alloys generally have higher raw material costs due to the price volatility of chromium but offer superior corrosion resistance, which can reduce maintenance expenses over time. Nickel-copper alloys tend to be more economical upfront, benefiting from lower material costs and good resistance to seawater corrosion, making them cost-effective for marine applications. Selecting between these alloys requires balancing initial procurement costs against long-term operational savings and specific environmental performance needs.

Environmental Impact and Sustainability

Nickel-chromium alloys exhibit superior corrosion resistance, reducing the frequency of replacement and minimizing waste in industrial applications, which supports environmental sustainability. In contrast, nickel-copper alloys are valued for their antimicrobial properties and recyclability, contributing to lower environmental footprints in marine and electronic industries. Sustainable practices favor nickel-chromium alloys when longevity is critical, while nickel-copper alloys offer eco-friendly benefits through efficient resource recovery and reduced ecosystem disruption.

Choosing the Right Alloy for Your Application

Nickel-chromium alloys offer exceptional corrosion resistance and high-temperature strength, making them ideal for aerospace and industrial heating applications. Nickel-copper alloys provide superior resistance to seawater corrosion and excellent thermal conductivity, suitable for marine and chemical processing environments. Selecting the right alloy depends on factors such as operating temperature, environmental exposure, and mechanical stress requirements specific to your application.

Nickel-Chromium Alloy vs Nickel-Copper Alloy Infographic

materialdif.com

materialdif.com