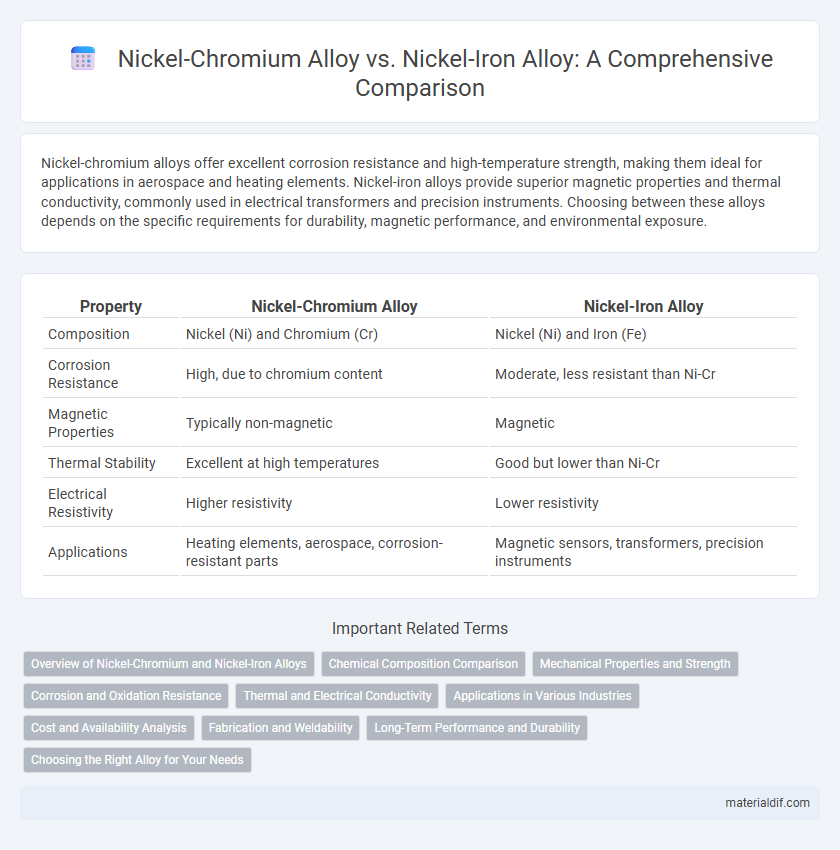

Nickel-chromium alloys offer excellent corrosion resistance and high-temperature strength, making them ideal for applications in aerospace and heating elements. Nickel-iron alloys provide superior magnetic properties and thermal conductivity, commonly used in electrical transformers and precision instruments. Choosing between these alloys depends on the specific requirements for durability, magnetic performance, and environmental exposure.

Table of Comparison

| Property | Nickel-Chromium Alloy | Nickel-Iron Alloy |

|---|---|---|

| Composition | Nickel (Ni) and Chromium (Cr) | Nickel (Ni) and Iron (Fe) |

| Corrosion Resistance | High, due to chromium content | Moderate, less resistant than Ni-Cr |

| Magnetic Properties | Typically non-magnetic | Magnetic |

| Thermal Stability | Excellent at high temperatures | Good but lower than Ni-Cr |

| Electrical Resistivity | Higher resistivity | Lower resistivity |

| Applications | Heating elements, aerospace, corrosion-resistant parts | Magnetic sensors, transformers, precision instruments |

Overview of Nickel-Chromium and Nickel-Iron Alloys

Nickel-chromium alloys are primarily valued for their exceptional corrosion resistance and high-temperature strength, commonly used in heating elements and aerospace applications. Nickel-iron alloys exhibit superior magnetic properties and thermal stability, making them ideal for electrical equipment and precise instrumentation. Both alloys offer unique blends of nickel with either chromium or iron, tailoring their mechanical and chemical traits to specific industrial needs.

Chemical Composition Comparison

Nickel-chromium alloys typically consist of 60-80% nickel and 15-25% chromium, providing enhanced corrosion resistance and high-temperature strength. In contrast, nickel-iron alloys contain approximately 30-50% nickel and 50-70% iron, resulting in superior magnetic properties and thermal expansion control. The chemical composition differences directly influence their suitability for applications such as high-temperature environments for nickel-chromium and magnetic devices or structural components for nickel-iron.

Mechanical Properties and Strength

Nickel-Chromium alloys exhibit superior mechanical strength and high-temperature resistance due to the chromium content that enhances hardness and oxidation resistance. Nickel-Iron alloys provide excellent ductility and toughness, maintaining strength under cyclic loading and thermal fluctuations common in industrial applications. Both alloys offer distinct advantages, with Nickel-Chromium favored for structural durability and Nickel-Iron optimized for flexibility and impact resistance.

Corrosion and Oxidation Resistance

Nickel-chromium alloys exhibit superior corrosion and oxidation resistance due to the formation of a stable chromium oxide layer that protects the surface in harsh environments. Nickel-iron alloys have reduced corrosion resistance compared to nickel-chromium alloys, as iron content tends to promote rusting and reduces oxidation stability. Due to their enhanced protective oxide barrier, nickel-chromium alloys are preferred in high-temperature and chemically aggressive applications requiring long-term durability.

Thermal and Electrical Conductivity

Nickel-chromium alloys exhibit lower thermal and electrical conductivity compared to nickel-iron alloys due to the presence of chromium, which disrupts electron flow and phonon propagation. Nickel-iron alloys maintain higher conductivity levels, making them preferable for applications requiring efficient heat dissipation and electrical current transmission. The difference in conductivity impacts their suitability in industries such as aerospace and electronics, where thermal management and electrical efficiency are critical.

Applications in Various Industries

Nickel-chromium alloys are extensively used in aerospace and automotive industries due to their exceptional corrosion resistance and high-temperature strength, making them ideal for turbine blades and exhaust systems. Nickel-iron alloys find applications in electrical and magnetic industries, particularly in manufacturing precision instruments and magnetic shielding components because of their superior magnetic permeability and thermal stability. Both alloys play crucial roles in chemical processing plants, with nickel-chromium alloys favored for handling aggressive environments and nickel-iron alloys utilized in structural components requiring dimensional stability.

Cost and Availability Analysis

Nickel-Chromium alloys generally have higher costs due to the premium price of chromium and the complex manufacturing process involved, while Nickel-Iron alloys tend to be more affordable because iron is abundant and less expensive. Availability of Nickel-Chromium alloys is often limited by chromium supply constraints and geopolitical factors, whereas Nickel-Iron alloys benefit from more stable nickel and iron supply chains, ensuring broader market access. Cost-efficiency and supply stability make Nickel-Iron alloys preferable for large-scale industrial applications where budget and consistent availability are critical.

Fabrication and Weldability

Nickel-Chromium alloys exhibit superior oxidation resistance and maintain strength at high temperatures, making their fabrication more demanding due to the need for controlled atmospheres and precise thermal management during welding. In contrast, Nickel-Iron alloys offer better weldability with less susceptibility to cracking and distortion, facilitating easier fabrication processes, especially in structural applications. The choice between these alloys depends on balancing corrosion resistance and mechanical performance against fabrication complexity and weld integrity.

Long-Term Performance and Durability

Nickel-chromium alloys exhibit superior corrosion resistance and high-temperature stability, making them ideal for long-term applications in harsh environments. Nickel-iron alloys offer enhanced magnetic properties and structural strength but may be more susceptible to oxidation over extended periods. For durability-focused projects requiring resistance to thermal degradation, nickel-chromium alloys typically provide a significant advantage in maintaining performance over time.

Choosing the Right Alloy for Your Needs

Nickel-chromium alloys offer superior corrosion resistance and high-temperature strength, making them ideal for applications in harsh chemical environments and aerospace components. Nickel-iron alloys provide excellent magnetic properties and thermal expansion control, suited for electrical devices and precision instruments. Selecting the right alloy depends on factors such as operating temperature, mechanical stress, corrosion exposure, and specific performance requirements in your application.

Nickel-Chromium Alloy vs Nickel-Iron Alloy Infographic

materialdif.com

materialdif.com