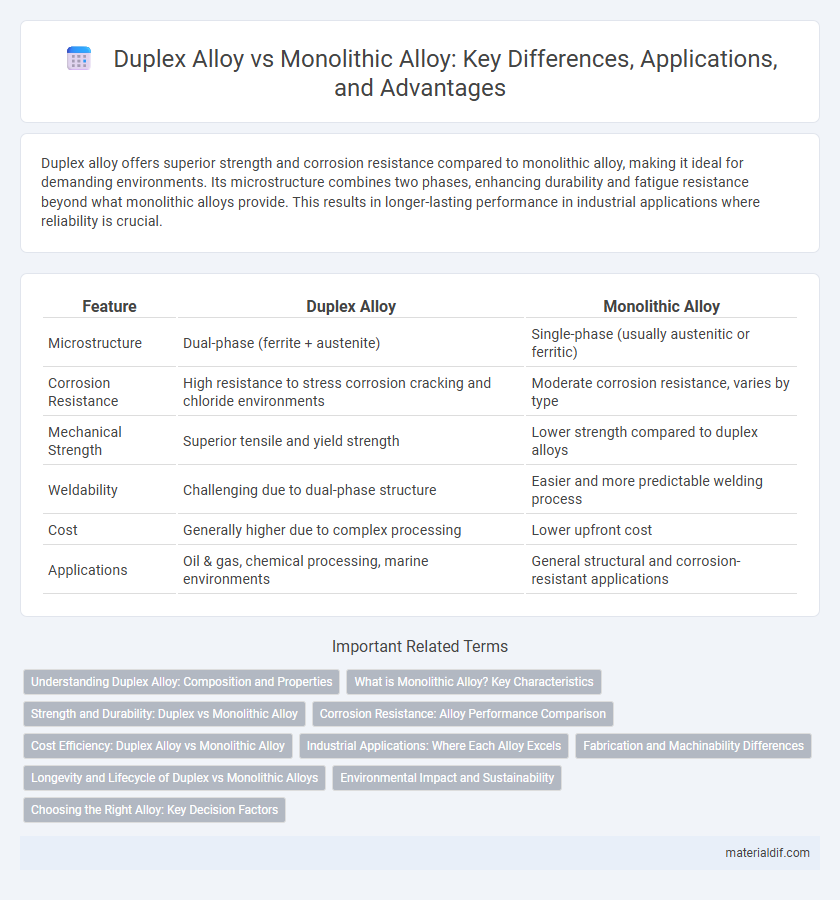

Duplex alloy offers superior strength and corrosion resistance compared to monolithic alloy, making it ideal for demanding environments. Its microstructure combines two phases, enhancing durability and fatigue resistance beyond what monolithic alloys provide. This results in longer-lasting performance in industrial applications where reliability is crucial.

Table of Comparison

| Feature | Duplex Alloy | Monolithic Alloy |

|---|---|---|

| Microstructure | Dual-phase (ferrite + austenite) | Single-phase (usually austenitic or ferritic) |

| Corrosion Resistance | High resistance to stress corrosion cracking and chloride environments | Moderate corrosion resistance, varies by type |

| Mechanical Strength | Superior tensile and yield strength | Lower strength compared to duplex alloys |

| Weldability | Challenging due to dual-phase structure | Easier and more predictable welding process |

| Cost | Generally higher due to complex processing | Lower upfront cost |

| Applications | Oil & gas, chemical processing, marine environments | General structural and corrosion-resistant applications |

Understanding Duplex Alloy: Composition and Properties

Duplex alloy consists of roughly equal proportions of austenite and ferrite phases, providing a unique microstructure that enhances strength and corrosion resistance compared to monolithic alloys. Its balanced composition offers superior resistance to stress corrosion cracking and improved toughness in harsh environments. Commonly found in applications requiring durability in aggressive chemical or marine conditions, duplex alloys outperform conventional monolithic stainless steels by combining the best characteristics of both phases.

What is Monolithic Alloy? Key Characteristics

Monolithic alloy refers to a single-phase metal composition characterized by uniform microstructure and consistent mechanical properties throughout the material. Key characteristics include high structural integrity, enhanced ductility, and improved resistance to corrosion due to its homogeneous nature. Unlike duplex alloys, which combine two distinct phases for specific performance benefits, monolithic alloys typically exhibit predictable behavior under stress and offer ease of fabrication.

Strength and Durability: Duplex vs Monolithic Alloy

Duplex alloys exhibit superior strength and enhanced corrosion resistance compared to monolithic alloys due to their two-phase microstructure combining austenitic and ferritic properties. This unique composition allows duplex alloys to withstand higher mechanical stress and aggressive environments, making them ideal for demanding applications. In contrast, monolithic alloys, with uniform microstructures, generally offer lower strength and durability in corrosive or high-stress conditions.

Corrosion Resistance: Alloy Performance Comparison

Duplex alloys exhibit superior corrosion resistance compared to monolithic alloys due to their balanced microstructure of austenite and ferrite phases, providing enhanced resistance to stress corrosion cracking and pitting. The combination of these phases improves the alloy's ability to withstand aggressive environments, such as chloride-rich solutions. Monolithic alloys, primarily composed of a single phase, often lack this dual-phase synergy, resulting in lower overall corrosion resistance under similar conditions.

Cost Efficiency: Duplex Alloy vs Monolithic Alloy

Duplex alloys offer enhanced cost efficiency compared to monolithic alloys due to their superior strength-to-weight ratio, which reduces material usage and overall manufacturing costs. The dual-phase microstructure of duplex alloys provides long-term durability and corrosion resistance, minimizing maintenance expenses over the product lifecycle. Monolithic alloys often require thicker sections or additional coatings to achieve similar performance, leading to higher initial and operational costs.

Industrial Applications: Where Each Alloy Excels

Duplex alloys offer superior corrosion resistance and high strength, making them ideal for harsh industrial environments such as chemical processing and offshore oil platforms. Monolithic alloys excel in applications requiring exceptional thermal conductivity and ease of fabrication, often used in automotive and aerospace components. The choice between duplex and monolithic alloys depends on specific industrial demands for durability, resistance, and mechanical performance.

Fabrication and Machinability Differences

Duplex alloys exhibit a balanced microstructure of austenite and ferrite phases, resulting in enhanced strength and corrosion resistance compared to monolithic alloys, which consist of a single phase. The fabrication of duplex alloys demands more precise control of heat treatment and welding parameters to maintain phase balance, whereas monolithic alloys allow more straightforward processing. Machinability in duplex alloys is generally lower due to their higher strength and work-hardening rate, requiring specialized tooling and machining strategies, while monolithic alloys are easier to machine but may lack the superior mechanical properties of duplex alloys.

Longevity and Lifecycle of Duplex vs Monolithic Alloys

Duplex alloys exhibit superior longevity compared to monolithic alloys due to their enhanced corrosion resistance and higher mechanical strength, which extend their operational lifecycle in harsh environments. Monolithic alloys often show faster degradation rates under stress and corrosive conditions, leading to more frequent maintenance and shorter replacement intervals. The balanced microstructure of duplex alloys delivers improved fatigue resistance, substantially increasing the service life when applied in critical infrastructure and industrial components.

Environmental Impact and Sustainability

Duplex alloys exhibit superior corrosion resistance and longer service life compared to monolithic alloys, reducing the frequency of replacements and the associated environmental footprint. Their enhanced durability minimizes raw material consumption and energy use in manufacturing, contributing to sustainability goals. Monolithic alloys, while sometimes cheaper initially, often require more frequent maintenance and replacement, leading to greater waste and environmental impact over time.

Choosing the Right Alloy: Key Decision Factors

Choosing the right alloy involves evaluating corrosion resistance, mechanical strength, and cost-efficiency between Duplex and Monolithic alloys. Duplex alloys offer superior corrosion resistance and higher tensile strength due to their dual-phase microstructure, making them ideal for harsh environments. Monolithic alloys, with their uniform composition, provide easier fabrication and lower initial cost, suitable for less demanding applications.

Duplex Alloy vs Monolithic Alloy Infographic

materialdif.com

materialdif.com