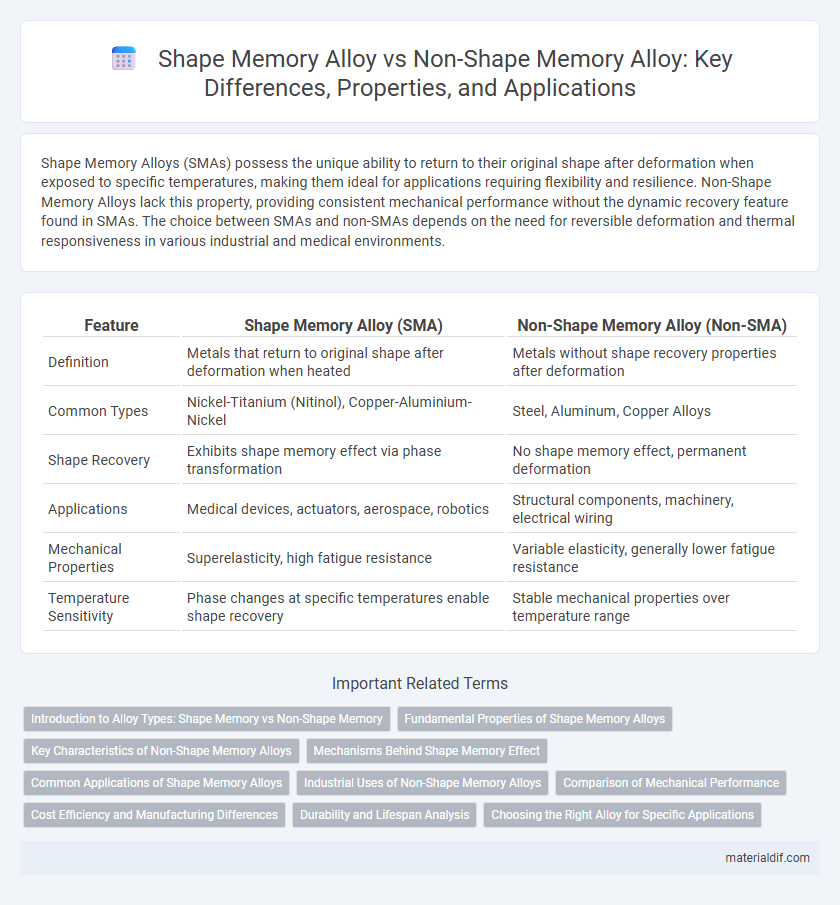

Shape Memory Alloys (SMAs) possess the unique ability to return to their original shape after deformation when exposed to specific temperatures, making them ideal for applications requiring flexibility and resilience. Non-Shape Memory Alloys lack this property, providing consistent mechanical performance without the dynamic recovery feature found in SMAs. The choice between SMAs and non-SMAs depends on the need for reversible deformation and thermal responsiveness in various industrial and medical environments.

Table of Comparison

| Feature | Shape Memory Alloy (SMA) | Non-Shape Memory Alloy (Non-SMA) |

|---|---|---|

| Definition | Metals that return to original shape after deformation when heated | Metals without shape recovery properties after deformation |

| Common Types | Nickel-Titanium (Nitinol), Copper-Aluminium-Nickel | Steel, Aluminum, Copper Alloys |

| Shape Recovery | Exhibits shape memory effect via phase transformation | No shape memory effect, permanent deformation |

| Applications | Medical devices, actuators, aerospace, robotics | Structural components, machinery, electrical wiring |

| Mechanical Properties | Superelasticity, high fatigue resistance | Variable elasticity, generally lower fatigue resistance |

| Temperature Sensitivity | Phase changes at specific temperatures enable shape recovery | Stable mechanical properties over temperature range |

Introduction to Alloy Types: Shape Memory vs Non-Shape Memory

Shape Memory Alloys (SMAs) exhibit the unique ability to return to their original shape after deformation through a thermal phase transformation, primarily comprising nickel-titanium (Nitinol) among common metals. In contrast, Non-Shape Memory Alloys lack this reversible transformation and maintain permanent deformation when stressed, often used where structural stability is critical. The distinct properties arise from differences in crystallographic phase changes, making SMAs ideal for applications requiring adaptability, while non-SMAs are preferred for consistent mechanical strength.

Fundamental Properties of Shape Memory Alloys

Shape Memory Alloys (SMAs) exhibit unique fundamental properties such as superelasticity and the ability to undergo reversible phase transformations between martensite and austenite, enabling them to return to their original shape after deformation. Unlike Non-Shape Memory Alloys, SMAs demonstrate thermoelastic martensitic transformation, allowing shape recovery upon heating. These alloys also possess high damping capacity and fatigue resistance, making them suitable for applications requiring deformation without permanent damage.

Key Characteristics of Non-Shape Memory Alloys

Non-shape memory alloys (non-SMAs) typically exhibit permanent deformation when subjected to mechanical stress, lacking the reversible phase transformation characteristic of shape memory alloys. These alloys generally possess higher strength and hardness but do not return to their original shape after deformation, making them suitable for applications requiring durability and stability without shape recovery. Common non-SMAs include stainless steel, brass, and aluminum alloys, which offer excellent corrosion resistance, machinability, and cost-effectiveness in various industrial uses.

Mechanisms Behind Shape Memory Effect

Shape memory alloys (SMAs) exhibit a unique ability to return to their original shape after deformation due to a reversible phase transformation between martensite and austenite structures, driven by temperature or stress changes. Non-shape memory alloys lack this reversible transformation and primarily deform through dislocation motion and plastic deformation without shape recoverability. The key mechanism behind the shape memory effect is the thermally or mechanically induced martensitic transformation that allows SMAs to "remember" and recover predetermined shapes.

Common Applications of Shape Memory Alloys

Shape Memory Alloys (SMAs) are widely used in medical devices such as stents and orthodontic wires due to their unique ability to return to a predefined shape after deformation. They are also employed in aerospace actuators and robotic components for their precise movement control and durability. In contrast, Non-Shape Memory Alloys find common applications in structural components and electrical connectors where shape recovery is not required.

Industrial Uses of Non-Shape Memory Alloys

Non-shape memory alloys (non-SMAs) are extensively used in industrial applications for their durability, corrosion resistance, and mechanical strength, making them ideal for structural components, automotive parts, and heavy machinery. Common non-SMAs such as stainless steel and bronze provide excellent wear resistance and stability under high stress, ensuring long service life in construction, aerospace, and manufacturing sectors. These alloys are favored for applications requiring consistent performance without deformation recovery, contrasting with shape memory alloys used in actuators and sensors.

Comparison of Mechanical Performance

Shape memory alloys (SMAs) exhibit unique mechanical performance characterized by superelasticity and the ability to undergo reversible phase transformations, allowing them to recover original shape after deformation. Non-shape memory alloys (non-SMAs) primarily rely on conventional elastic and plastic deformation, lacking the intrinsic ability to self-recover. SMAs provide enhanced fatigue resistance and energy absorption compared to non-SMAs, making them ideal for applications requiring durability and adaptive response.

Cost Efficiency and Manufacturing Differences

Shape memory alloys (SMAs) typically have higher material costs due to complex alloy compositions like nickel-titanium, but their ability to return to a predetermined shape enables reduced machining and assembly expenses, enhancing overall cost efficiency in specialized applications. Non-shape memory alloys generally offer lower raw material costs and simpler manufacturing processes, such as casting and forging, resulting in faster production cycles but lack the adaptive functionality of SMAs. Manufacturing differences stem from SMAs requiring precise thermal treatments and controlled deformation cycles to activate shape memory effects, whereas non-SMAs rely on conventional heat treatments and mechanical work to achieve desired properties.

Durability and Lifespan Analysis

Shape Memory Alloys (SMAs) exhibit superior durability due to their ability to return to their original shape after deformation, enhancing their lifespan in cyclic applications compared to Non-Shape Memory Alloys (non-SMAs). SMAs like Nitinol resist fatigue and mechanical wear better by absorbing and recovering strain energy, leading to longer operational life in dynamic environments. Non-SMAs lack this self-recovery feature, making them more prone to permanent deformation, reduced durability, and shorter lifespan under repeated stress conditions.

Choosing the Right Alloy for Specific Applications

Shape Memory Alloys (SMAs) such as Nitinol exhibit unique properties like superelasticity and the ability to return to a pre-defined shape after deformation, making them ideal for medical devices, actuators, and aerospace applications requiring precise mechanical responses. Non-Shape Memory Alloys, including common steels and aluminum alloys, offer superior strength, corrosion resistance, and cost-effectiveness for structural components, automotive parts, and general manufacturing where shape recovery is unnecessary. Selecting the appropriate alloy depends on application-specific performance requirements such as stress resilience, temperature range, fatigue resistance, and cost constraints to optimize functionality and durability.

Shape Memory Alloy vs Non-Shape Memory Alloy Infographic

materialdif.com

materialdif.com