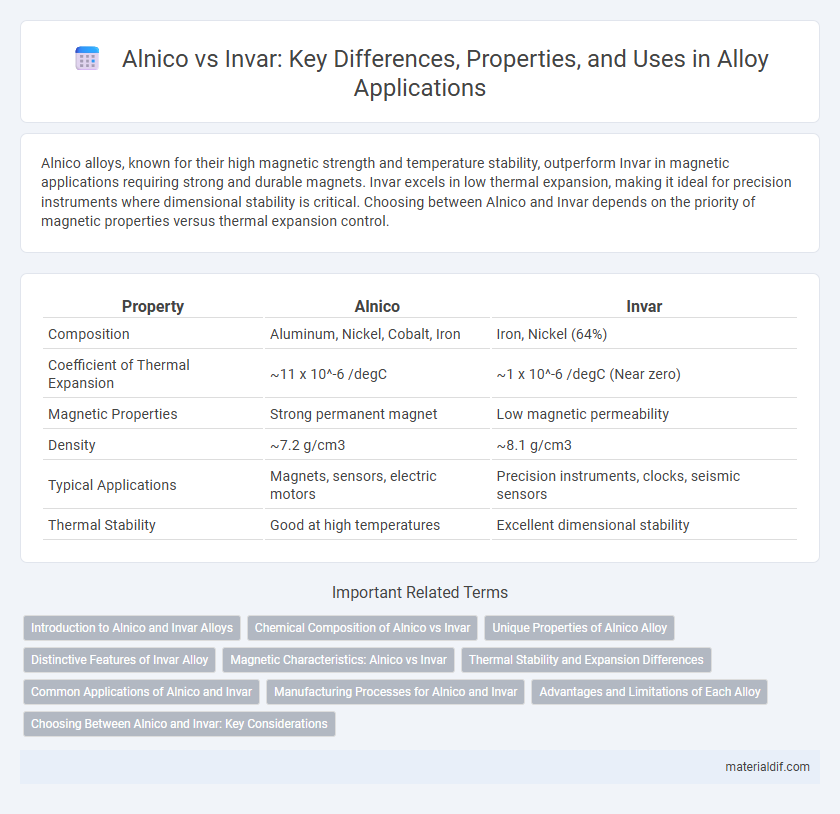

Alnico alloys, known for their high magnetic strength and temperature stability, outperform Invar in magnetic applications requiring strong and durable magnets. Invar excels in low thermal expansion, making it ideal for precision instruments where dimensional stability is critical. Choosing between Alnico and Invar depends on the priority of magnetic properties versus thermal expansion control.

Table of Comparison

| Property | Alnico | Invar |

|---|---|---|

| Composition | Aluminum, Nickel, Cobalt, Iron | Iron, Nickel (64%) |

| Coefficient of Thermal Expansion | ~11 x 10^-6 /degC | ~1 x 10^-6 /degC (Near zero) |

| Magnetic Properties | Strong permanent magnet | Low magnetic permeability |

| Density | ~7.2 g/cm3 | ~8.1 g/cm3 |

| Typical Applications | Magnets, sensors, electric motors | Precision instruments, clocks, seismic sensors |

| Thermal Stability | Good at high temperatures | Excellent dimensional stability |

Introduction to Alnico and Invar Alloys

Alnico alloys, composed primarily of aluminum, nickel, and cobalt, are known for their exceptional magnetic properties and high-temperature stability, making them ideal for permanent magnets and electric motors. Invar alloys, consisting mainly of iron and nickel, exhibit minimal thermal expansion, which makes them crucial in precision instruments and applications requiring dimensional stability under temperature variations. Both Alnico and Invar alloys highlight the specialized use of metal compositions tailored to performance in magnetic and thermal environments.

Chemical Composition of Alnico vs Invar

Alnico is primarily composed of aluminum (Al), nickel (Ni), and cobalt (Co), often combined with iron (Fe) and small amounts of copper (Cu) and titanium (Ti), forming a magnetic alloy with excellent magnetic properties. Invar consists mainly of iron (Fe) and approximately 36% nickel (Ni), creating a low-expansion alloy known for its minimal thermal expansion. The distinct chemical compositions of Alnico and Invar define their unique magnetic and thermal behaviors, with Alnico optimized for magnetism and Invar engineered for dimensional stability.

Unique Properties of Alnico Alloy

Alnico alloys exhibit exceptional magnetic properties, including high coercivity and strong remanence, making them ideal for permanent magnets in electric motors and sensors. Their unique composition, primarily aluminum, nickel, cobalt, and iron, imparts excellent thermal stability and corrosion resistance compared to Invar, which is primarily valued for its low thermal expansion. This combination of magnetic strength and durability positions Alnico as a superior choice in applications requiring reliable performance under varying temperature conditions.

Distinctive Features of Invar Alloy

Invar alloy is renowned for its exceptionally low coefficient of thermal expansion, typically around 1.2 x 10^-6 /degC, making it ideal for precision instruments and applications requiring dimensional stability under temperature changes. Unlike Alnico, which is primarily valued for its magnetic properties due to high levels of aluminum, nickel, and cobalt, Invar's unique nickel-iron composition (approximately 64% iron, 36% nickel) delivers minimal thermal expansion with relatively low magnetism. This distinctive combination enables Invar to maintain structural integrity in precision engineering, aerospace, and scientific instruments, differentiating it fundamentally from the magnetic focus of Alnico alloys.

Magnetic Characteristics: Alnico vs Invar

Alnico alloys exhibit strong magnetic properties with high coercivity and moderate remanence, making them ideal for permanent magnets in motors and sensors. Invar alloys, by contrast, have minimal magnetic responsiveness due to their low magnetic permeability and are primarily valued for their near-zero thermal expansion rather than magnetism. The distinct magnetic characteristics of Alnico versus Invar directly influence their application, with Alnico favored for magnetic performance and Invar for dimensional stability under temperature variations.

Thermal Stability and Expansion Differences

Alnico alloys exhibit higher thermal expansion rates compared to Invar, resulting in less dimensional stability under temperature fluctuations. Invar, known for its exceptionally low thermal expansion coefficient near room temperature, maintains dimensional precision in applications requiring minimal thermal deformation. The enhanced thermal stability of Invar makes it preferred over Alnico in precision instruments and temperature-sensitive structural components.

Common Applications of Alnico and Invar

Alnico alloys, composed primarily of aluminum, nickel, and cobalt, are widely used in permanent magnets for electric motors, sensors, and microphones due to their high magnetic strength and temperature stability. Invar, an iron-nickel alloy known for its extremely low coefficient of thermal expansion, is commonly applied in precision instruments, scientific measurement devices, and clock pendulums where dimensional stability with temperature changes is crucial. Both alloys serve distinct roles in industries such as aerospace, electronics, and instrumentation based on their unique magnetic and thermal properties.

Manufacturing Processes for Alnico and Invar

Alnico alloys undergo casting and sintering manufacturing processes that involve precise control over temperature and cooling rates to achieve optimal magnetic properties and grain structure. Invar, primarily composed of iron and nickel, requires meticulous cold working and annealing stages to ensure its nearly zero thermal expansion, demanding stringent process control to avoid structural distortions. Both alloys depend on tailored thermal treatments to enhance their unique physical characteristics, directly impacting their performance in specialized industrial applications.

Advantages and Limitations of Each Alloy

Alnico alloys offer excellent magnetic properties, such as high magnetic strength and temperature stability, making them ideal for permanent magnet applications in electric motors and sensors. However, Alnico's brittleness and susceptibility to corrosion limit its use in demanding mechanical environments without protective coatings. Invar alloys excel in maintaining low thermal expansion, which ensures high dimensional stability in precision instruments and aerospace components, but their relatively low strength and poor magnetic properties restrict their applications in structural or magnetic roles.

Choosing Between Alnico and Invar: Key Considerations

Choosing between Alnico and Invar alloys depends on the specific application requirements such as magnetic properties, thermal expansion, and temperature stability. Alnico offers strong magnetic performance and high temperature resistance, making it ideal for magnetic sensors and motors, while Invar provides extremely low thermal expansion suitable for precision instruments and dimensional stability in varying temperatures. Cost, machinability, and environmental conditions also play critical roles in selecting the appropriate alloy for industrial or scientific use.

Alnico vs Invar Infographic

materialdif.com

materialdif.com