Alloy plating involves applying a thin layer of alloy metal onto the surface of a base material through electroplating, enhancing corrosion resistance and aesthetic appeal without significantly altering the substrate's dimensions. Alloy cladding, on the other hand, bonds a thicker layer of alloy material to a base metal, providing superior mechanical strength, durability, and improved wear resistance for industrial applications. Choosing between alloy plating and alloy cladding depends on the required surface properties and the extent of protection needed for the specific use case.

Table of Comparison

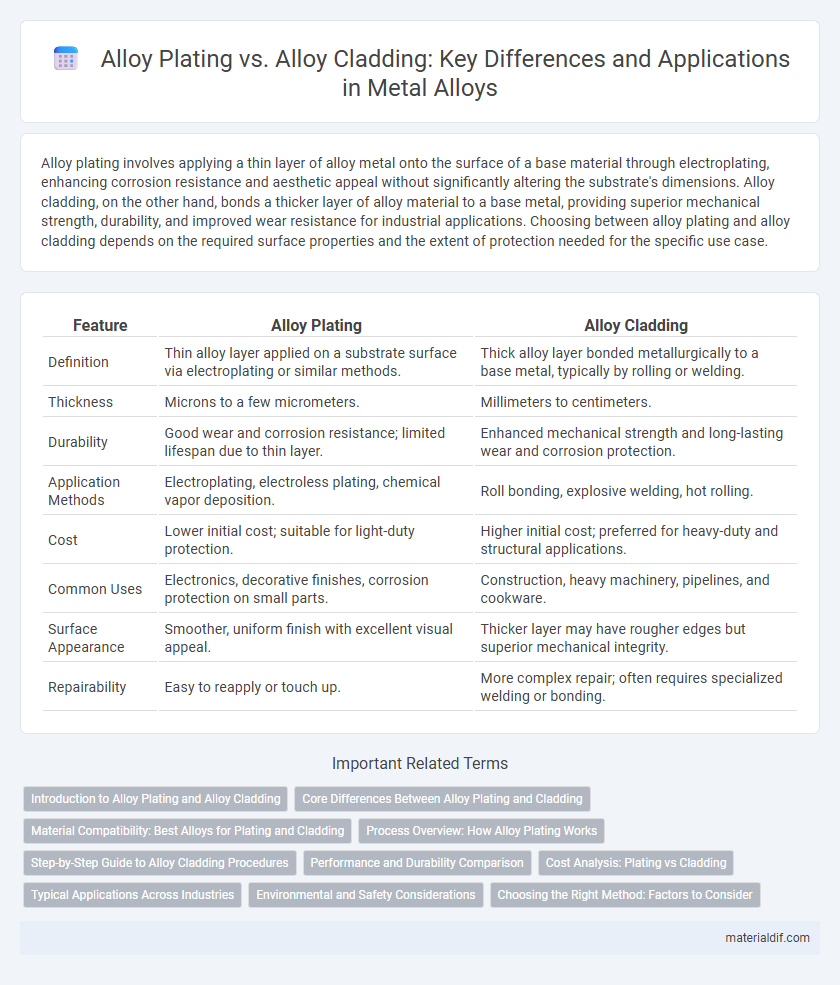

| Feature | Alloy Plating | Alloy Cladding |

|---|---|---|

| Definition | Thin alloy layer applied on a substrate surface via electroplating or similar methods. | Thick alloy layer bonded metallurgically to a base metal, typically by rolling or welding. |

| Thickness | Microns to a few micrometers. | Millimeters to centimeters. |

| Durability | Good wear and corrosion resistance; limited lifespan due to thin layer. | Enhanced mechanical strength and long-lasting wear and corrosion protection. |

| Application Methods | Electroplating, electroless plating, chemical vapor deposition. | Roll bonding, explosive welding, hot rolling. |

| Cost | Lower initial cost; suitable for light-duty protection. | Higher initial cost; preferred for heavy-duty and structural applications. |

| Common Uses | Electronics, decorative finishes, corrosion protection on small parts. | Construction, heavy machinery, pipelines, and cookware. |

| Surface Appearance | Smoother, uniform finish with excellent visual appeal. | Thicker layer may have rougher edges but superior mechanical integrity. |

| Repairability | Easy to reapply or touch up. | More complex repair; often requires specialized welding or bonding. |

Introduction to Alloy Plating and Alloy Cladding

Alloy plating involves depositing a thin layer of a metal alloy onto the surface of a substrate to enhance corrosion resistance, wear resistance, and aesthetic appeal. Alloy cladding, on the other hand, consists of bonding a thicker alloy layer to a base metal through processes like roll bonding or explosive welding, providing improved structural strength and durability. Both techniques optimize material properties but differ significantly in thickness, application methods, and functional performance.

Core Differences Between Alloy Plating and Cladding

Alloy plating involves applying a thin layer of alloy metal onto a substrate surface through electrochemical or chemical deposition, enhancing corrosion resistance and surface hardness. Alloy cladding is a process that bonds a thicker layer of alloy metal onto a base metal via mechanical or metallurgical means, providing improved structural integrity and wear resistance. Core differences include plating's thin, surface-level coverage versus cladding's substantial, bonded layer that affects the metal's bulk properties.

Material Compatibility: Best Alloys for Plating and Cladding

Alloy plating offers superior corrosion resistance when applied to compatible substrates like stainless steel, nickel, and copper alloys, ensuring durable, thin-layer protection for precise electronic and automotive components. In contrast, alloy cladding involves bonding thicker alloy layers such as aluminum, titanium, or copper alloys onto base metals, enhancing structural integrity and wear resistance for heavy-duty applications in aerospace and construction. Selecting materials like nickel-cobalt alloys for plating or aluminum-copper clads for cladding optimizes bonding strength and thermal expansion compatibility, crucial for long-term performance.

Process Overview: How Alloy Plating Works

Alloy plating involves depositing a thin, uniform layer of metal alloy onto a substrate through electrochemical or electroless processes, enhancing corrosion resistance and surface hardness. The process typically begins with surface preparation, followed by immersion in an electrolyte bath containing metal ions, where controlled current or chemical reactions deposit the alloy coating. This method ensures strong adhesion and precise thickness control compared to alloy cladding, which mechanically bonds thicker alloy layers to the base material.

Step-by-Step Guide to Alloy Cladding Procedures

Alloy cladding involves applying a metallurgically bonded layer of alloy onto a base metal through processes like hot rolling or explosive welding, enhancing corrosion resistance and mechanical strength. The step-by-step procedure for alloy cladding typically includes surface preparation by cleaning and grit blasting, precise alignment of alloy and base metal plates, and controlled heat and pressure application to achieve a uniform metallurgical bond. Post-process inspection using ultrasonic testing and metallographic analysis ensures cladding integrity and performance in demanding industrial applications.

Performance and Durability Comparison

Alloy plating offers a thinner, more uniform coating that enhances surface hardness and corrosion resistance but may wear faster under heavy mechanical stress compared to alloy cladding. Alloy cladding provides a thicker, metallurgically bonded layer that delivers superior durability and impact resistance, making it ideal for applications requiring extended service life in harsh environments. Performance-wise, alloy cladding excels in long-term corrosion protection and mechanical strength, while alloy plating is preferred for precision coatings and cost-effective surface enhancement.

Cost Analysis: Plating vs Cladding

Alloy plating generally offers a lower upfront cost compared to alloy cladding due to its thinner deposition layer and simpler application process. In contrast, alloy cladding, while more expensive initially, provides superior durability and resistance to wear, reducing long-term maintenance and replacement expenses. Cost efficiency depends on the specific application, with plating suitable for light-duty uses and cladding preferred for heavy-duty requirements.

Typical Applications Across Industries

Alloy plating is predominantly used in electronics, automotive, and aerospace industries for corrosion resistance and enhanced conductivity, often applied to connectors and circuit boards. Alloy cladding finds widespread use in construction, chemical processing, and power generation sectors, providing a robust, corrosion-resistant barrier on structural components and pressure vessels. Both techniques improve material performance but are selected based on application demands such as thickness, durability, and environmental exposure.

Environmental and Safety Considerations

Alloy plating involves electrochemical deposition of a metal alloy onto a substrate, producing a thin, uniform protective layer that minimizes environmental waste through reduced material usage and lower energy consumption. Alloy cladding, which bonds a thick alloy layer to a base metal via welding or rolling, typically requires higher energy input and may generate more hazardous byproducts, increasing environmental and safety risks such as metal fume exposure and thermal hazards. Selecting alloy plating over cladding can significantly improve workplace safety by reducing airborne contaminants and minimizing the ecological footprint associated with heavy metal processing.

Choosing the Right Method: Factors to Consider

Selecting between alloy plating and alloy cladding depends on factors such as desired surface thickness, durability requirements, and cost efficiency. Alloy plating offers a thinner, uniform coating ideal for corrosion resistance and aesthetic enhancement, while alloy cladding provides a thicker, metallurgically bonded layer suited for structural strength and wear resistance. Material compatibility, application environment, and maintenance needs also play critical roles in determining the optimal method for specific industrial or manufacturing applications.

Alloy Plating vs Alloy Cladding Infographic

materialdif.com

materialdif.com