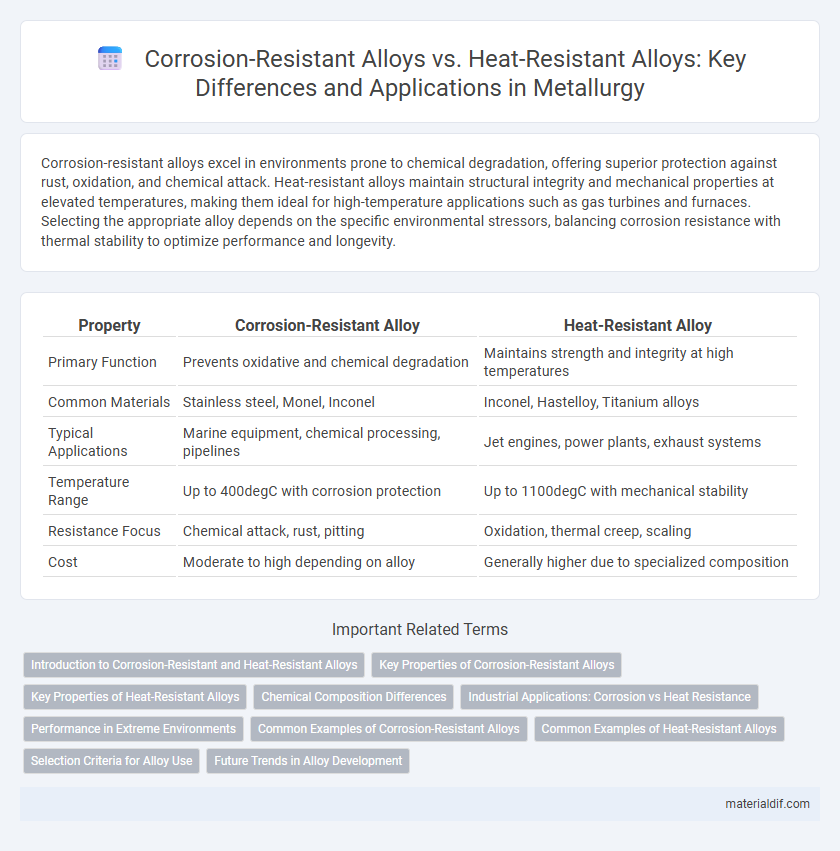

Corrosion-resistant alloys excel in environments prone to chemical degradation, offering superior protection against rust, oxidation, and chemical attack. Heat-resistant alloys maintain structural integrity and mechanical properties at elevated temperatures, making them ideal for high-temperature applications such as gas turbines and furnaces. Selecting the appropriate alloy depends on the specific environmental stressors, balancing corrosion resistance with thermal stability to optimize performance and longevity.

Table of Comparison

| Property | Corrosion-Resistant Alloy | Heat-Resistant Alloy |

|---|---|---|

| Primary Function | Prevents oxidative and chemical degradation | Maintains strength and integrity at high temperatures |

| Common Materials | Stainless steel, Monel, Inconel | Inconel, Hastelloy, Titanium alloys |

| Typical Applications | Marine equipment, chemical processing, pipelines | Jet engines, power plants, exhaust systems |

| Temperature Range | Up to 400degC with corrosion protection | Up to 1100degC with mechanical stability |

| Resistance Focus | Chemical attack, rust, pitting | Oxidation, thermal creep, scaling |

| Cost | Moderate to high depending on alloy | Generally higher due to specialized composition |

Introduction to Corrosion-Resistant and Heat-Resistant Alloys

Corrosion-resistant alloys, such as stainless steel and nickel-based alloys, are engineered to withstand chemical degradation caused by environmental exposure, making them ideal for applications in marine and chemical processing industries. Heat-resistant alloys, including Inconel and Hastelloy, maintain mechanical strength and oxidation resistance at elevated temperatures, commonly used in aerospace and power generation sectors. Understanding the distinct properties of these alloys enables optimized material selection for environments involving either chemical corrosion or high thermal stress.

Key Properties of Corrosion-Resistant Alloys

Corrosion-resistant alloys exhibit exceptional resistance to oxidation, chemical degradation, and environmental wear, making them ideal for harsh conditions involving acids, seawater, or industrial pollutants. These alloys typically contain high amounts of chromium, nickel, and molybdenum, which form protective oxide layers crucial for preventing corrosive damage. Their key properties include superior pitting resistance, stress corrosion cracking resistance, and long-term durability in aggressive environments.

Key Properties of Heat-Resistant Alloys

Heat-resistant alloys exhibit exceptional resistance to oxidation and scaling at elevated temperatures, maintaining mechanical strength and structural integrity in environments exceeding 1000degC. These alloys often contain elements like chromium, nickel, and cobalt, which enhance their high-temperature stability and creep resistance. Their microstructure is engineered to prevent grain growth and phase transformation, ensuring durability under thermal cycling and mechanical stress.

Chemical Composition Differences

Corrosion-resistant alloys typically contain high percentages of chromium (often above 10.5%) and nickel, which form a passive oxide layer protecting against oxidation and chemical attack, whereas heat-resistant alloys emphasize elements like chromium, molybdenum, and cobalt to maintain strength and oxidation resistance at elevated temperatures. The chemical composition of corrosion-resistant alloys prioritizes elements that enhance resistance to acids, salts, and moisture, with additions such as molybdenum and nitrogen improving pitting and crevice corrosion resistance. Heat-resistant alloys feature specific stabilizers like silicon and aluminum to bolster scaling resistance, optimizing performance under thermal stress rather than chemical degradation.

Industrial Applications: Corrosion vs Heat Resistance

Corrosion-resistant alloys, such as stainless steel and nickel-based alloys, are extensively used in chemical processing, marine environments, and wastewater treatment to withstand aggressive corrosive agents and extend equipment lifespan. Heat-resistant alloys, including Inconel and Hastelloy, are preferred in aerospace, power generation, and automotive industries where components endure extreme temperatures and thermal cycling. Selecting the appropriate alloy based on its corrosion or heat resistance directly impacts the durability and performance of industrial machinery and infrastructure under specific environmental conditions.

Performance in Extreme Environments

Corrosion-resistant alloys excel in extreme environments by providing superior resistance to chemical degradation, preventing surface deterioration in highly acidic or saline conditions. Heat-resistant alloys maintain mechanical strength and structural integrity at elevated temperatures, ensuring durability under prolonged thermal stress. Selecting the appropriate alloy depends on the specific environmental challenge, whether aggressive corrosion or intense heat exposure.

Common Examples of Corrosion-Resistant Alloys

Corrosion-resistant alloys commonly include stainless steel, Inconel, and Monel, each designed to withstand harsh environments by forming protective oxide layers that prevent rust and degradation. These alloys are extensively used in marine, chemical processing, and medical industries due to their superior resistance to oxidation and chemical attack. Their unique compositions, often enriched with chromium, nickel, and molybdenum, enhance durability in corrosive atmospheres compared to heat-resistant alloys primarily formulated to maintain strength at elevated temperatures.

Common Examples of Heat-Resistant Alloys

Heat-resistant alloys commonly include Inconel, Hastelloy, and stainless steel grades such as 310 and 321, known for their ability to withstand high temperatures without losing strength. These alloys are primarily used in aerospace, power generation, and chemical processing industries where thermal stability and oxidation resistance are critical. Unlike corrosion-resistant alloys optimized to prevent chemical degradation, heat-resistant alloys maintain mechanical integrity under extreme thermal stress.

Selection Criteria for Alloy Use

Corrosion-resistant alloys are selected primarily for environments exposed to moisture, chemicals, or saltwater, ensuring longevity and structural integrity by preventing oxidation and material degradation. Heat-resistant alloys are chosen for applications involving high temperatures, where maintaining mechanical strength and oxidation resistance at elevated heat levels is critical. Selection criteria hinge on environmental conditions, mechanical performance requirements, and the specific chemical composition tailored to resist corrosion or withstand thermal stress.

Future Trends in Alloy Development

Emerging trends in alloy development emphasize the integration of advanced corrosion-resistant elements such as chromium and molybdenum to enhance durability in harsh environments. Heat-resistant alloys are evolving with the incorporation of nickel and cobalt-based compositions tailored for higher thermal stability and oxidation resistance, meeting the demands of industries like aerospace and power generation. Ongoing research is focused on optimizing microstructures through additive manufacturing techniques, enabling the creation of alloys with superior performance and extended service life under extreme conditions.

Corrosion-resistant alloy vs Heat-resistant alloy Infographic

materialdif.com

materialdif.com