Duplex stainless steel offers a unique combination of austenitic and ferritic microstructures, resulting in superior strength and excellent corrosion resistance compared to ferritic stainless steel, which primarily consists of a single-phase ferritic structure. While ferritic stainless steel provides good resistance to stress corrosion cracking and has magnetic properties, duplex stainless steel excels in applications requiring enhanced pitting and crevice corrosion resistance. The choice between duplex and ferritic stainless steel depends on specific environmental conditions and mechanical requirements, with duplex alloys often favored for more demanding, high-performance uses.

Table of Comparison

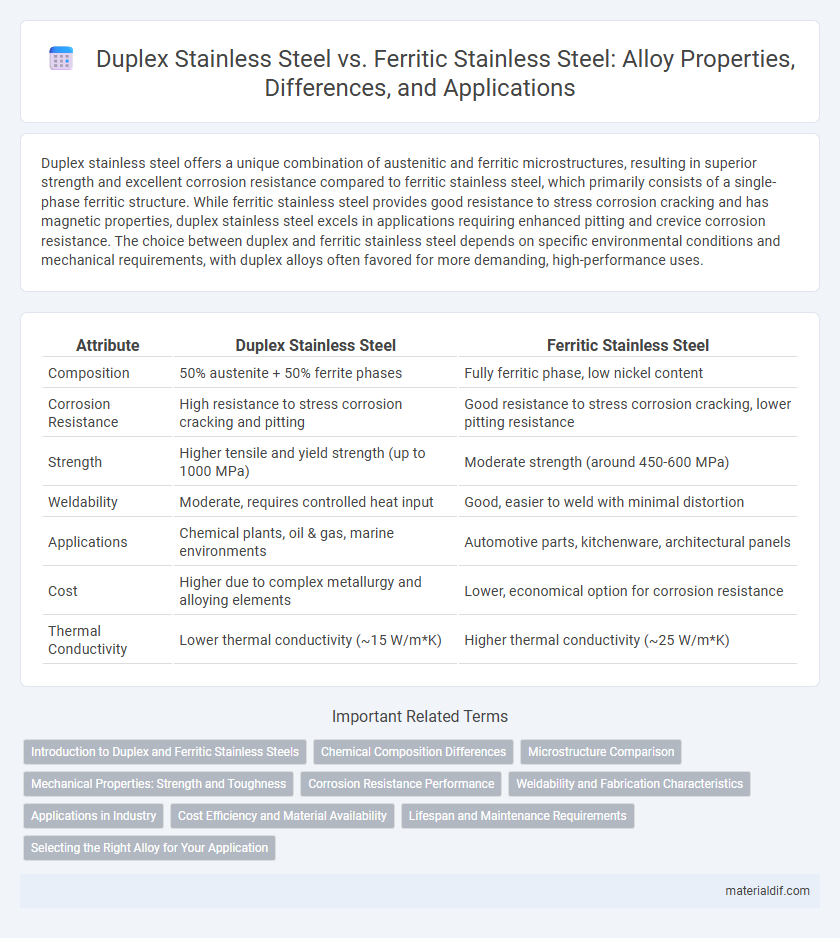

| Attribute | Duplex Stainless Steel | Ferritic Stainless Steel |

|---|---|---|

| Composition | 50% austenite + 50% ferrite phases | Fully ferritic phase, low nickel content |

| Corrosion Resistance | High resistance to stress corrosion cracking and pitting | Good resistance to stress corrosion cracking, lower pitting resistance |

| Strength | Higher tensile and yield strength (up to 1000 MPa) | Moderate strength (around 450-600 MPa) |

| Weldability | Moderate, requires controlled heat input | Good, easier to weld with minimal distortion |

| Applications | Chemical plants, oil & gas, marine environments | Automotive parts, kitchenware, architectural panels |

| Cost | Higher due to complex metallurgy and alloying elements | Lower, economical option for corrosion resistance |

| Thermal Conductivity | Lower thermal conductivity (~15 W/m*K) | Higher thermal conductivity (~25 W/m*K) |

Introduction to Duplex and Ferritic Stainless Steels

Duplex stainless steel combines austenitic and ferritic microstructures, offering enhanced strength and corrosion resistance compared to ferritic stainless steel, which primarily consists of a body-centered cubic ferrite phase. Duplex alloys excel in chloride-rich environments, making them ideal for chemical processing and marine applications, whereas ferritic stainless steels are valued for their resistance to stress corrosion cracking and good thermal conductivity. Both types provide unique benefits in construction and industrial settings, with duplex steels bridging the performance gap between austenitic and ferritic grades.

Chemical Composition Differences

Duplex stainless steel contains roughly equal proportions of austenite and ferrite phases, with typical alloying elements including 20-25% chromium, 5-7% nickel, 3-4.5% molybdenum, and nitrogen additions that enhance strength and corrosion resistance. Ferritic stainless steel is primarily composed of 10.5-30% chromium, very low carbon content, and lacks significant nickel, resulting in a body-centered cubic crystal structure with superior resistance to stress corrosion cracking but lower toughness. The key chemical composition difference lies in duplex steels' balanced chromium and nickel content combined with molybdenum and nitrogen, versus ferritic stainless steels' high chromium and minimal nickel, impacting their mechanical properties and corrosion behaviors.

Microstructure Comparison

Duplex stainless steel features a balanced microstructure of approximately 50% austenite and 50% ferrite, providing a unique combination of strength and corrosion resistance. Ferritic stainless steel primarily consists of a body-centered cubic ferrite phase, offering good stress corrosion cracking resistance but with lower toughness and weldability compared to duplex grades. This dual-phase structure in duplex steels enhances mechanical properties and corrosion resistance, outperforming the single-phase ferritic microstructure in demanding environments.

Mechanical Properties: Strength and Toughness

Duplex stainless steel exhibits superior mechanical properties, combining high strength with excellent toughness due to its dual-phase microstructure consisting of roughly equal parts of austenite and ferrite. Ferritic stainless steel offers moderate strength and good toughness but generally falls short of the enhanced yield strength and impact resistance found in duplex grades. The unique balance of tensile strength, yield strength (up to 70 ksi for duplex), and improved resistance to stress corrosion cracking makes duplex stainless steel ideal for demanding structural applications.

Corrosion Resistance Performance

Duplex stainless steel exhibits superior corrosion resistance compared to ferritic stainless steel due to its balanced microstructure of austenite and ferrite, which enhances resistance to pitting, crevice, and stress corrosion cracking. It offers exceptional performance in chloride-rich environments and high-temperature conditions, making it ideal for marine and chemical processing applications. Ferritic stainless steel, while corrosion-resistant in mildly oxidizing environments, generally shows inferior protection against localized corrosion mechanisms found in harsher settings.

Weldability and Fabrication Characteristics

Duplex stainless steel offers superior weldability compared to ferritic stainless steel due to its balanced microstructure, which reduces the risk of cracking and enhances corrosion resistance in welded joints. Fabrication of duplex steel benefits from its higher strength and toughness, requiring careful control of heat input to maintain phase balance and prevent embrittlement. In contrast, ferritic stainless steel has limited weldability caused by its lower ductility and susceptibility to grain growth, often necessitating preheating and post-weld heat treatment to improve joint quality.

Applications in Industry

Duplex stainless steel is widely used in chemical processing, oil and gas, and marine industries due to its excellent corrosion resistance and high strength, especially in chloride-rich environments. Ferritic stainless steel is favored in automotive exhaust systems, kitchen appliances, and architectural applications because of its good stress corrosion cracking resistance and magnetic properties. Both alloys offer cost-effective solutions based on their specific mechanical properties and environmental durability requirements in industrial applications.

Cost Efficiency and Material Availability

Duplex stainless steel offers superior cost efficiency due to its higher strength, allowing for thinner sections and reduced material usage compared to ferritic stainless steel. Ferritic stainless steel generally has better material availability and lower initial cost, making it suitable for less demanding applications. Selecting between them depends on balancing initial investment with long-term performance and maintenance costs.

Lifespan and Maintenance Requirements

Duplex stainless steel offers a significantly longer lifespan compared to ferritic stainless steel due to its superior resistance to corrosion, especially in chloride-rich environments. Its balanced microstructure combines austenitic and ferritic phases, reducing susceptibility to stress corrosion cracking and minimizing maintenance frequency. Ferritic stainless steel, while cost-effective, requires more frequent inspections and maintenance to address its higher vulnerability to sensitization and stress corrosion, leading to shorter service life in demanding conditions.

Selecting the Right Alloy for Your Application

Duplex stainless steel offers superior corrosion resistance and high strength, making it ideal for harsh environments such as chemical processing and marine applications, while ferritic stainless steel is better suited for moderate corrosion conditions and applications requiring good thermal conductivity like automotive exhaust systems. Duplex alloys typically have a balanced microstructure of austenitic and ferritic phases, providing enhanced toughness and resistance to stress corrosion cracking compared to the single-phase ferritic steels. Selecting the right alloy depends on factors such as exposure to chloride environments, mechanical stress, and weldability demands to optimize performance and longevity.

Duplex stainless steel vs Ferritic stainless steel Infographic

materialdif.com

materialdif.com