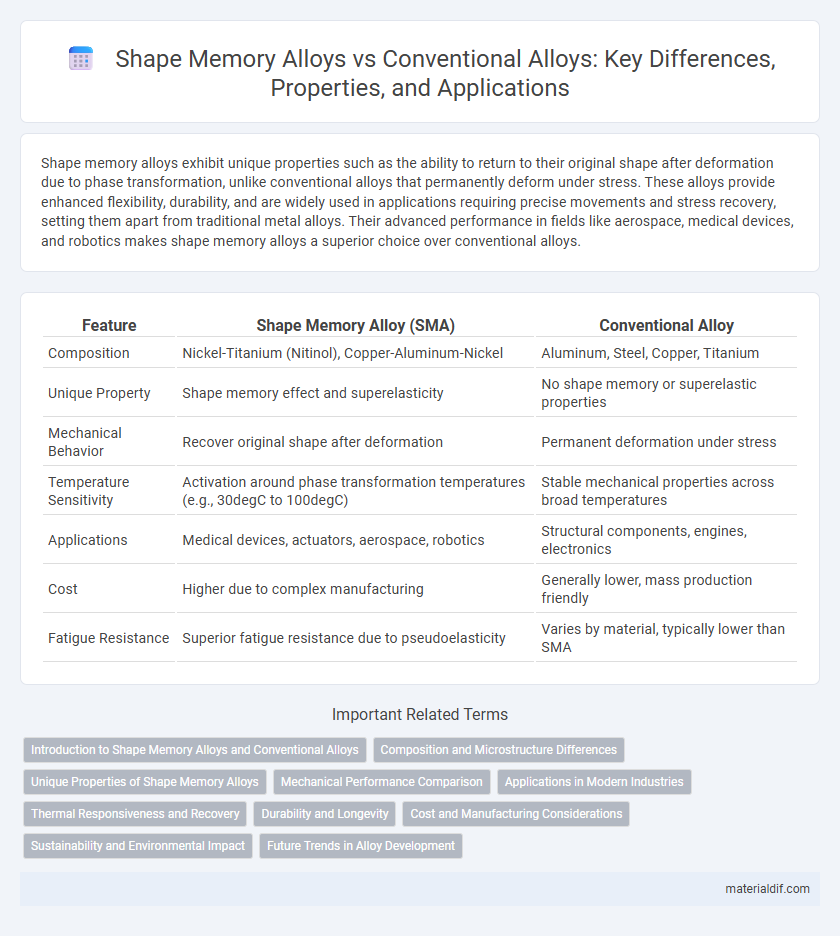

Shape memory alloys exhibit unique properties such as the ability to return to their original shape after deformation due to phase transformation, unlike conventional alloys that permanently deform under stress. These alloys provide enhanced flexibility, durability, and are widely used in applications requiring precise movements and stress recovery, setting them apart from traditional metal alloys. Their advanced performance in fields like aerospace, medical devices, and robotics makes shape memory alloys a superior choice over conventional alloys.

Table of Comparison

| Feature | Shape Memory Alloy (SMA) | Conventional Alloy |

|---|---|---|

| Composition | Nickel-Titanium (Nitinol), Copper-Aluminum-Nickel | Aluminum, Steel, Copper, Titanium |

| Unique Property | Shape memory effect and superelasticity | No shape memory or superelastic properties |

| Mechanical Behavior | Recover original shape after deformation | Permanent deformation under stress |

| Temperature Sensitivity | Activation around phase transformation temperatures (e.g., 30degC to 100degC) | Stable mechanical properties across broad temperatures |

| Applications | Medical devices, actuators, aerospace, robotics | Structural components, engines, electronics |

| Cost | Higher due to complex manufacturing | Generally lower, mass production friendly |

| Fatigue Resistance | Superior fatigue resistance due to pseudoelasticity | Varies by material, typically lower than SMA |

Introduction to Shape Memory Alloys and Conventional Alloys

Shape Memory Alloys (SMAs) are advanced metallic materials that exhibit the unique ability to return to their original shape after deformation through a reversible phase transformation, primarily utilized in biomedical devices and aerospace applications. Conventional alloys consist of a mixture of two or more metals, designed to enhance properties such as strength, corrosion resistance, and durability without the shape memory effect. The distinctive thermoelastic martensitic transformation in SMAs differentiates them from conventional alloys, enabling smart actuation and self-healing capabilities.

Composition and Microstructure Differences

Shape memory alloys (SMAs) primarily consist of specific compositions such as nickel-titanium (NiTi), which exhibit a unique phase transformation between martensite and austenite microstructures responsible for their shape memory effect. Conventional alloys, including stainless steels or aluminum alloys, maintain stable microstructures like face-centered cubic (FCC) or body-centered cubic (BCC) phases that do not undergo reversible phase transformations. The distinct compositional ratio and thermoelastic martensitic transformation in SMAs enable their ability to return to a pre-defined shape, in contrast to the permanent deformation behavior of conventional alloys.

Unique Properties of Shape Memory Alloys

Shape Memory Alloys (SMAs) exhibit unique properties such as superelasticity and the ability to return to a predetermined shape after deformation, which conventional alloys lack. These alloys undergo reversible phase transformations between martensite and austenite phases, enabling high energy absorption and exceptional fatigue resistance. Their distinct thermal-mechanical characteristics make SMAs ideal for applications in medical devices, aerospace, and robotics.

Mechanical Performance Comparison

Shape Memory Alloys (SMAs) exhibit exceptional mechanical performance by undergoing reversible phase transformations, enabling superelasticity and shape recovery after deformation, which conventional alloys lack. Conventional alloys primarily rely on elastic and plastic deformation, resulting in permanent shape changes under stress, while SMAs can sustain higher strains and recover their original shape without damage. This unique behavior of SMAs offers superior fatigue resistance, energy absorption, and durability compared to traditional metals in cyclic loading applications.

Applications in Modern Industries

Shape memory alloys (SMAs) exhibit unique thermomechanical properties, enabling applications in aerospace actuators, biomedical stents, and robotics where precise movement and recovery are essential. Conventional alloys, valued for their strength and durability, dominate structural components in automotive, construction, and manufacturing industries. Integration of SMAs in smart devices enhances adaptive functionality beyond the capabilities of traditional alloys, driving innovation in modern industrial applications.

Thermal Responsiveness and Recovery

Shape Memory Alloys (SMAs) exhibit superior thermal responsiveness compared to conventional alloys, rapidly changing shape when exposed to specific temperature thresholds due to their unique thermomechanical properties. SMAs recover their original shape through a reversible phase transformation between martensite and austenite structures, enabling precise and repeatable actuation. In contrast, conventional alloys lack this phase transformation capability, resulting in limited thermal recovery and reduced responsiveness under temperature variations.

Durability and Longevity

Shape Memory Alloys exhibit superior durability compared to conventional alloys due to their unique ability to undergo deformation and return to their original shape without permanent damage. These alloys maintain structural integrity over extensive cyclic loading, which significantly extends their longevity in applications such as biomedical devices and aerospace components. Conventional alloys, while strong, often suffer from fatigue and wear over time, leading to reduced lifespan and frequent maintenance requirements.

Cost and Manufacturing Considerations

Shape Memory Alloys (SMAs) typically incur higher costs than conventional alloys due to complex manufacturing processes such as precise thermal treatments and specialized alloying elements like nickel and titanium. Conventional alloys benefit from established, scalable production techniques and readily available raw materials, resulting in lower fabrication expenses. Manufacturing SMAs requires strict quality control and advanced equipment to ensure functional properties like superelasticity and phase transformation, impacting overall cost-effectiveness in industrial applications.

Sustainability and Environmental Impact

Shape memory alloys (SMAs) offer enhanced sustainability compared to conventional alloys through their ability to undergo reversible deformation, reducing material waste and extending product lifespan in applications such as aerospace and medical devices. Conventional alloys often require frequent replacement due to fatigue and irreversible damage, leading to greater resource consumption and higher environmental impact from mining and manufacturing processes. The recyclability and energy efficiency of SMAs contribute to lower carbon footprints, aligning with green engineering principles and sustainable material development.

Future Trends in Alloy Development

Shape Memory Alloys (SMAs) are rapidly advancing with innovations in composition and processing techniques that enhance their thermal and mechanical responsiveness compared to conventional alloys. Future trends focus on integrating nanotechnology and additive manufacturing to create alloys with improved fatigue resistance and tailored phase transformation temperatures. Research aims to expand applications in aerospace, biomedical devices, and robotics by developing multifunctional SMAs with smart sensing and actuating capabilities.

Shape Memory Alloy vs Conventional Alloy Infographic

materialdif.com

materialdif.com