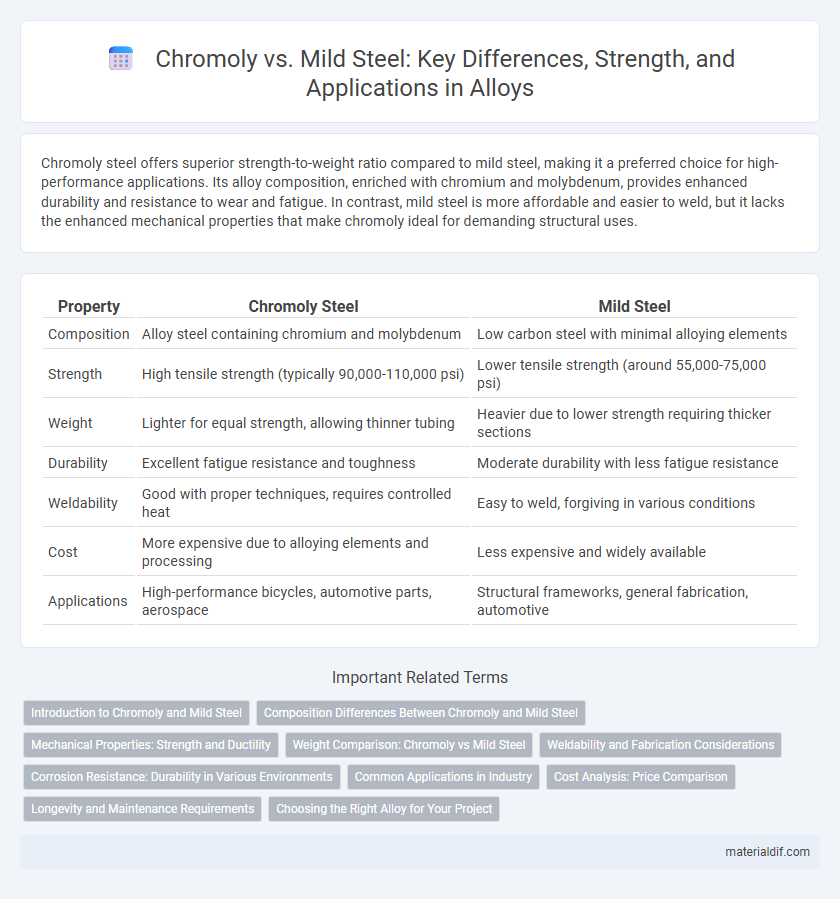

Chromoly steel offers superior strength-to-weight ratio compared to mild steel, making it a preferred choice for high-performance applications. Its alloy composition, enriched with chromium and molybdenum, provides enhanced durability and resistance to wear and fatigue. In contrast, mild steel is more affordable and easier to weld, but it lacks the enhanced mechanical properties that make chromoly ideal for demanding structural uses.

Table of Comparison

| Property | Chromoly Steel | Mild Steel |

|---|---|---|

| Composition | Alloy steel containing chromium and molybdenum | Low carbon steel with minimal alloying elements |

| Strength | High tensile strength (typically 90,000-110,000 psi) | Lower tensile strength (around 55,000-75,000 psi) |

| Weight | Lighter for equal strength, allowing thinner tubing | Heavier due to lower strength requiring thicker sections |

| Durability | Excellent fatigue resistance and toughness | Moderate durability with less fatigue resistance |

| Weldability | Good with proper techniques, requires controlled heat | Easy to weld, forgiving in various conditions |

| Cost | More expensive due to alloying elements and processing | Less expensive and widely available |

| Applications | High-performance bicycles, automotive parts, aerospace | Structural frameworks, general fabrication, automotive |

Introduction to Chromoly and Mild Steel

Chromoly, an alloy steel containing chromium and molybdenum, offers superior strength and resistance to corrosion compared to mild steel, which is a low-carbon steel primarily composed of iron and carbon. Chromoly is widely used in high-performance applications such as aerospace, automotive, and bicycle manufacturing due to its excellent tensile strength and lightweight properties. Mild steel, known for its affordability and ease of welding, is commonly utilized in construction and manufacturing where high strength is less critical.

Composition Differences Between Chromoly and Mild Steel

Chromoly steel contains a specific alloy composition, primarily chromium (around 0.8-1.1%) and molybdenum (about 0.15-0.25%), which significantly enhances its strength and corrosion resistance compared to mild steel. Mild steel consists mostly of iron with a low carbon content (typically 0.05-0.25%) and minimal alloying elements, resulting in lower tensile strength and less durability. The distinct alloying elements in Chromoly steel contribute to superior mechanical properties and improved heat resistance, making it ideal for applications requiring robust performance.

Mechanical Properties: Strength and Ductility

Chromoly steel, an alloy primarily composed of chromium and molybdenum, exhibits significantly higher tensile strength and yield strength compared to mild steel, making it ideal for applications requiring enhanced durability. Mild steel, with lower carbon content and minimal alloying elements, offers greater ductility and ease of welding but sacrifices strength and fatigue resistance. The superior mechanical properties of chromoly, such as improved toughness and better stress-strain behavior, make it a preferred choice for high-performance structural components and aerospace applications.

Weight Comparison: Chromoly vs Mild Steel

Chromoly steel typically weighs less than mild steel due to its higher strength-to-weight ratio, allowing for thinner, lighter components without sacrificing durability. Mild steel is denser and requires thicker sections to achieve similar strength, resulting in increased weight. This makes Chromoly a preferred choice for applications where weight reduction is critical, such as in bicycle frames and automotive components.

Weldability and Fabrication Considerations

Chromoly steel offers superior weldability compared to mild steel due to its alloy composition, which enhances heat resistance and reduces distortion during welding processes. Fabrication with chromoly requires controlled preheating and post-weld heat treatment to avoid cracking, whereas mild steel is more forgiving with fewer heat treatment needs. The alloy's strength-to-weight ratio enables lighter, stronger welded structures, making chromoly ideal for high-performance applications despite its more stringent fabrication requirements.

Corrosion Resistance: Durability in Various Environments

Chromoly steel offers superior corrosion resistance compared to mild steel due to its alloying elements like chromium and molybdenum, which enhance durability in harsh environments. Mild steel lacks these protective elements, making it more susceptible to rust and degradation when exposed to moisture and chemicals. Consequently, Chromoly's enhanced corrosion resistance ensures longer lifespan and reliability in applications ranging from automotive frames to aerospace components.

Common Applications in Industry

Chromoly steel, known for its high strength-to-weight ratio and excellent fatigue resistance, is commonly used in aerospace, automotive racing frames, and high-performance bicycle manufacturing. Mild steel, favored for its affordability and ease of welding, finds widespread applications in construction, structural beams, and general fabrication projects. Industries prioritize chromoly when durability and weight reduction are critical, while mild steel is chosen for cost-effective, large-scale manufacturing and infrastructure development.

Cost Analysis: Price Comparison

Chromoly steel typically commands a higher price than mild steel due to its alloy composition, which includes chromium and molybdenum, enhancing strength and durability. Mild steel remains more cost-effective for applications requiring less tensile strength and corrosion resistance, making it a budget-friendly option in manufacturing. Price variations are influenced by market demand, production scale, and specific grades, with Chromoly favored in high-performance industries despite its premium cost.

Longevity and Maintenance Requirements

Chromoly steel offers superior longevity due to its higher tensile strength and enhanced resistance to fatigue and corrosion compared to mild steel. Its alloy composition requires less frequent maintenance, reducing rust buildup and structural wear over time. Mild steel, while more affordable, demands regular upkeep such as repainting and rust prevention treatments to maintain its durability.

Choosing the Right Alloy for Your Project

Chromoly steel offers superior strength-to-weight ratio and enhanced durability compared to mild steel, making it ideal for high-performance applications like aerospace and automotive frames. Mild steel is more cost-effective and easier to weld, suitable for general fabrication and low-stress projects. Selecting the right alloy depends on balancing factors such as strength requirements, weight constraints, corrosion resistance, and budget considerations for your specific project.

Chromoly vs Mild Steel Infographic

materialdif.com

materialdif.com