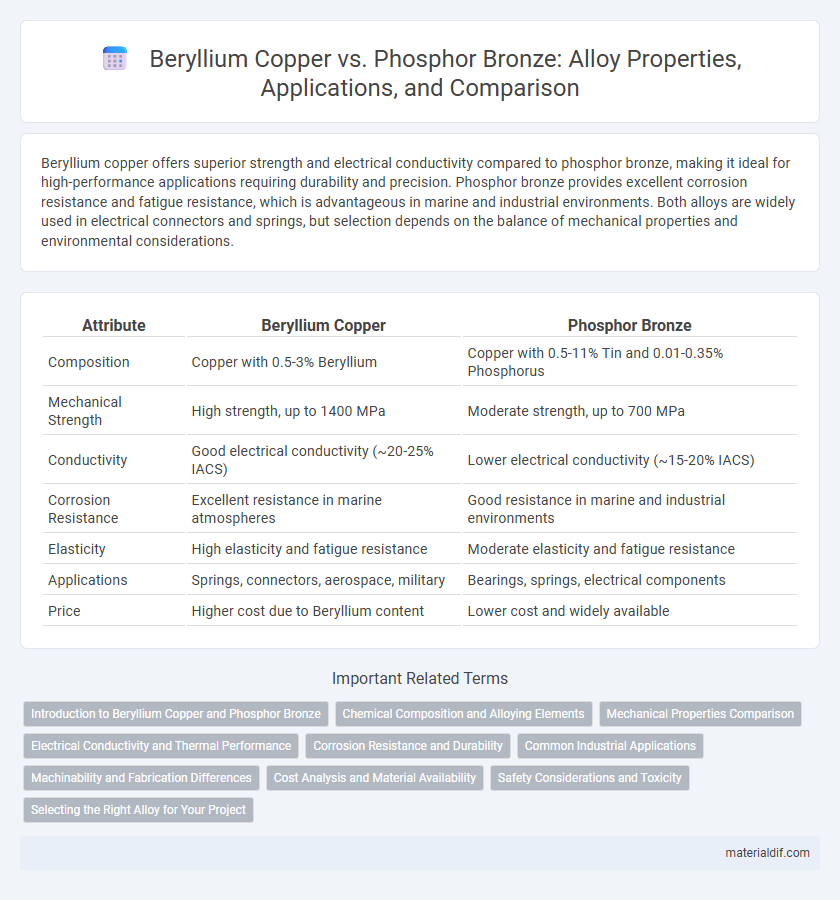

Beryllium copper offers superior strength and electrical conductivity compared to phosphor bronze, making it ideal for high-performance applications requiring durability and precision. Phosphor bronze provides excellent corrosion resistance and fatigue resistance, which is advantageous in marine and industrial environments. Both alloys are widely used in electrical connectors and springs, but selection depends on the balance of mechanical properties and environmental considerations.

Table of Comparison

| Attribute | Beryllium Copper | Phosphor Bronze |

|---|---|---|

| Composition | Copper with 0.5-3% Beryllium | Copper with 0.5-11% Tin and 0.01-0.35% Phosphorus |

| Mechanical Strength | High strength, up to 1400 MPa | Moderate strength, up to 700 MPa |

| Conductivity | Good electrical conductivity (~20-25% IACS) | Lower electrical conductivity (~15-20% IACS) |

| Corrosion Resistance | Excellent resistance in marine atmospheres | Good resistance in marine and industrial environments |

| Elasticity | High elasticity and fatigue resistance | Moderate elasticity and fatigue resistance |

| Applications | Springs, connectors, aerospace, military | Bearings, springs, electrical components |

| Price | Higher cost due to Beryllium content | Lower cost and widely available |

Introduction to Beryllium Copper and Phosphor Bronze

Beryllium copper is a copper alloy known for its exceptional strength, electrical conductivity, and corrosion resistance, commonly used in aerospace, electronics, and tooling applications. Phosphor bronze is a copper alloy containing tin and phosphorus, prized for its toughness, wear resistance, and low friction properties, making it ideal for springs, bearings, and electrical connectors. Both alloys exhibit distinct mechanical and chemical characteristics that suit specialized industrial uses based on performance requirements.

Chemical Composition and Alloying Elements

Beryllium Copper alloy typically contains 0.5-3% beryllium combined with copper, enhancing strength and electrical conductivity. Phosphor Bronze consists mainly of copper with 0.5-11% tin and small amounts of phosphorus, improving wear resistance and corrosion resistance. The presence of beryllium in Beryllium Copper provides superior hardness and fatigue strength compared to the tin and phosphorus elements in Phosphor Bronze.

Mechanical Properties Comparison

Beryllium copper exhibits higher tensile strength, typically ranging from 1,200 to 1,400 MPa, compared to phosphor bronze's tensile strength of approximately 550 to 1,100 MPa. It also boasts superior elasticity with a modulus of elasticity around 130-140 GPa, whereas phosphor bronze ranges between 100-125 GPa. These mechanical properties make beryllium copper more suitable for applications requiring high strength and fatigue resistance, while phosphor bronze offers better corrosion resistance and wear properties.

Electrical Conductivity and Thermal Performance

Beryllium copper exhibits superior electrical conductivity, typically around 20-25% IACS, and excellent thermal performance with high thermal conductivity, making it ideal for applications requiring efficient heat dissipation. Phosphor bronze, with electrical conductivity ranging from 10-15% IACS, offers moderate thermal conductivity but excels in corrosion resistance and mechanical strength. The choice between these alloys depends on the balance of conductivity, thermal management, and mechanical properties needed for specific electrical or thermal applications.

Corrosion Resistance and Durability

Beryllium Copper demonstrates superior corrosion resistance compared to Phosphor Bronze, making it ideal for harsh environments where oxidation and chemical exposure are concerns. Phosphor Bronze offers excellent durability with higher fatigue resistance, suitable for applications requiring repeated stress cycles. Both alloys provide robust performance, but Beryllium Copper is preferred for long-term corrosion protection while Phosphor Bronze excels in mechanical longevity.

Common Industrial Applications

Beryllium Copper is widely used in electrical connectors, precision instruments, and aerospace components due to its superior electrical conductivity and high strength. Phosphor Bronze finds common applications in marine hardware, springs, and electrical contacts because of its excellent corrosion resistance and fatigue durability. Both alloys serve critical roles in industries demanding reliable performance under mechanical stress and environmental exposure.

Machinability and Fabrication Differences

Beryllium copper exhibits superior machinability compared to phosphor bronze due to its high strength and thermal conductivity, allowing for faster cutting speeds and longer tool life. Phosphor bronze offers enhanced corrosion resistance and is easier to fabricate through processes like stamping and forming but can cause more rapid tool wear during machining. Manufacturers often select beryllium copper for precision components requiring intricate machining, while phosphor bronze is preferred in applications demanding better corrosion resistance and simpler fabrication methods.

Cost Analysis and Material Availability

Beryllium Copper typically commands a higher price than Phosphor Bronze due to its superior hardness, electrical conductivity, and corrosion resistance, impacting project budgets where cost efficiency is critical. Phosphor Bronze is more widely available and offers a cost-effective alternative in applications requiring good fatigue resistance and machinability, making it favorable in large-scale manufacturing. Material suppliers often stock Phosphor Bronze in greater quantities, reducing lead times and overall procurement costs compared to the more specialized Beryllium Copper.

Safety Considerations and Toxicity

Beryllium copper poses significant safety risks due to the toxicity of beryllium dust and fumes released during machining, which can cause chronic beryllium disease and requires strict handling protocols and protective equipment. Phosphor bronze is generally safer, exhibiting low toxicity and fewer health hazards, making it suitable for applications with minimal exposure risks. Proper ventilation and protective measures are crucial when working with beryllium copper to prevent inhalation and skin exposure to hazardous particles.

Selecting the Right Alloy for Your Project

Beryllium copper offers exceptional strength, electrical conductivity, and fatigue resistance, making it ideal for high-performance electrical connectors and precision instruments. Phosphor bronze provides excellent corrosion resistance, good electrical conductivity, and superior wear resistance, suitable for marine hardware and springs. Selecting the right alloy depends on balancing mechanical properties, corrosion environment, and conductivity requirements specific to your project needs.

Beryllium Copper vs Phosphor Bronze Infographic

materialdif.com

materialdif.com