Titanium alloy offers superior strength-to-weight ratio and excellent corrosion resistance, making it ideal for aerospace and medical applications where weight savings and durability are critical. Inconel, a nickel-chromium-based superalloy, excels in high-temperature environments due to its exceptional oxidation and thermal resistance, commonly used in jet engines and gas turbines. Choosing between titanium alloy and Inconel depends on temperature requirements, weight constraints, and corrosion resistance needs.

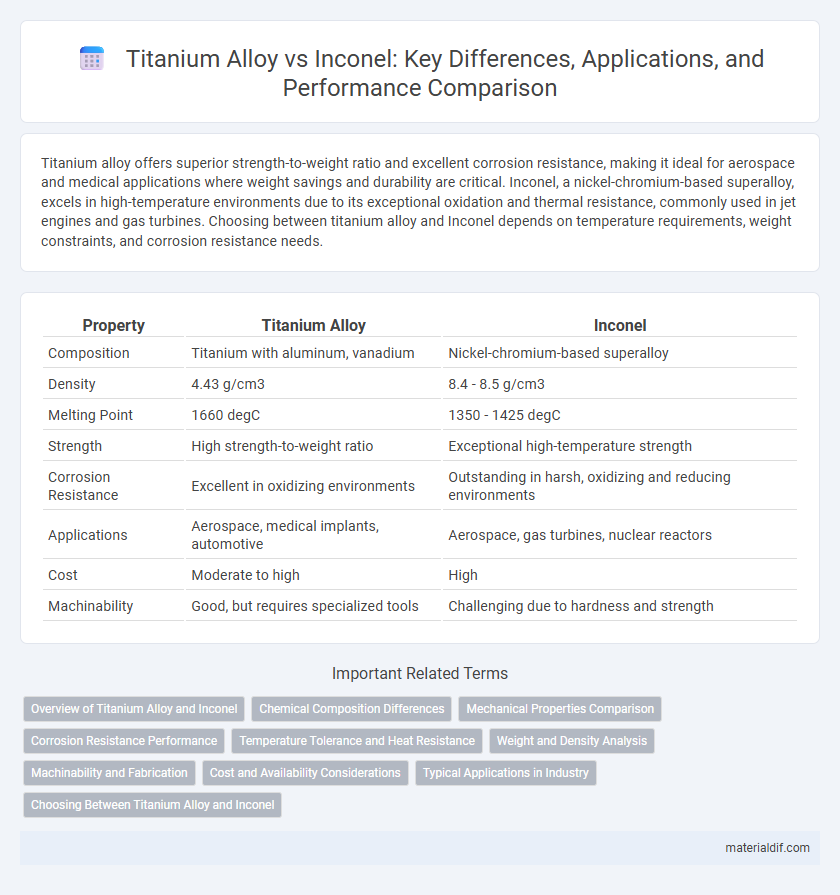

Table of Comparison

| Property | Titanium Alloy | Inconel |

|---|---|---|

| Composition | Titanium with aluminum, vanadium | Nickel-chromium-based superalloy |

| Density | 4.43 g/cm3 | 8.4 - 8.5 g/cm3 |

| Melting Point | 1660 degC | 1350 - 1425 degC |

| Strength | High strength-to-weight ratio | Exceptional high-temperature strength |

| Corrosion Resistance | Excellent in oxidizing environments | Outstanding in harsh, oxidizing and reducing environments |

| Applications | Aerospace, medical implants, automotive | Aerospace, gas turbines, nuclear reactors |

| Cost | Moderate to high | High |

| Machinability | Good, but requires specialized tools | Challenging due to hardness and strength |

Overview of Titanium Alloy and Inconel

Titanium alloys offer exceptional strength-to-weight ratios, outstanding corrosion resistance, and excellent biocompatibility, making them ideal for aerospace, medical implants, and marine applications. Inconel, a nickel-chromium superalloy, excels in high-temperature environments due to its remarkable oxidation and corrosion resistance, often used in gas turbines, jet engines, and chemical processing equipment. Both materials provide superior performance under extreme conditions, but titanium alloys emphasize lightweight durability, while Inconel prioritizes thermal stability and resistance to harsh chemical exposure.

Chemical Composition Differences

Titanium alloys primarily consist of titanium with small amounts of aluminum, vanadium, and other elements enhancing strength and corrosion resistance. Inconel is a nickel-chromium-based superalloy featuring significant chromium, iron, and molybdenum content, which provides excellent oxidation and high-temperature resistance. The stark contrast in base metals--titanium versus nickel-chromium--drives distinct chemical properties adapted for aerospace, marine, and industrial applications.

Mechanical Properties Comparison

Titanium alloys exhibit a superior strength-to-weight ratio compared to Inconel, making them ideal for aerospace applications requiring lightweight materials with high tensile strength. Inconel alloys, primarily nickel-chromium-based, offer exceptional creep resistance and oxidation stability at temperatures exceeding 700degC, outperforming titanium alloys in high-temperature environments. While titanium alloys deliver greater fatigue resistance and corrosion resistance in marine settings, Inconel alloys dominate in extreme heat and chemically aggressive conditions due to their robust mechanical strength retention.

Corrosion Resistance Performance

Titanium alloy demonstrates superior corrosion resistance in acidic and chloride-rich environments due to its stable oxide film, making it ideal for aerospace and marine applications. Inconel, a nickel-chromium-based superalloy, excels in high-temperature corrosion resistance, particularly against oxidation and carburization in extreme heat settings. Both alloys offer robust corrosion resistance, but titanium alloy is preferred for chemical resistance while Inconel suits environments with intense thermal and oxidative stress.

Temperature Tolerance and Heat Resistance

Titanium alloys offer excellent temperature tolerance up to approximately 600degC, making them suitable for aerospace and automotive applications requiring lightweight strength. Inconel, a nickel-chromium-based superalloy, outperforms titanium alloys in heat resistance, maintaining structural integrity at extreme temperatures exceeding 1000degC. The superior oxidation and corrosion resistance of Inconel under high thermal stress enables its use in gas turbines and jet engines where elevated temperature performance is critical.

Weight and Density Analysis

Titanium alloys exhibit a significantly lower density, approximately 4.5 g/cm3, compared to Inconel's density of around 8.4 to 8.7 g/cm3, making titanium alloys nearly 40-50% lighter for equivalent volume. This lightweight characteristic enhances fuel efficiency and structural performance in aerospace and automotive applications where weight reduction is critical. Despite Inconel's superior strength and oxidation resistance at high temperatures, the weight advantage of titanium alloys makes them preferable for components prioritizing low mass without compromising durability.

Machinability and Fabrication

Titanium alloys exhibit superior machinability compared to Inconel due to their lower hardness and thermal conductivity, resulting in reduced tool wear and faster cutting speeds. Inconel's high strength and oxidation resistance make it more difficult to machine, often requiring specialized tooling and slower feed rates. Fabrication processes for titanium alloys typically involve less thermal distortion, whereas Inconel demands strict control of heat input to prevent cracking and maintain structural integrity.

Cost and Availability Considerations

Titanium alloy generally offers a higher cost due to complex extraction and processing methods, whereas Inconel is more expensive owing to its nickel content and specialized manufacturing requirements. Availability of titanium alloy is more limited as it relies on scarce titanium ores, while Inconel benefits from wider accessibility in industrial supply chains. Cost-efficiency in applications depends heavily on the specific performance needs and procurement scale of these high-performance alloys.

Typical Applications in Industry

Titanium alloys are widely used in aerospace industries for aircraft structural components, medical devices, and marine applications due to their high strength-to-weight ratio and corrosion resistance. Inconel alloys find typical applications in extreme environments such as gas turbines, heat exchangers, and chemical processing plants because of their exceptional oxidation and heat resistance properties. Both alloys serve critical roles in industries requiring durability and performance under harsh conditions.

Choosing Between Titanium Alloy and Inconel

Titanium alloy offers superior strength-to-weight ratio and excellent corrosion resistance, making it ideal for aerospace and biomedical applications where weight savings and biocompatibility are critical. Inconel, a nickel-chromium-based superalloy, excels in high-temperature environments with exceptional oxidation and creep resistance, suitable for jet engines and gas turbines. Choosing between titanium alloy and Inconel depends on balancing factors like operating temperature, mechanical strength requirements, corrosion resistance, and cost efficiency for specific industrial applications.

Titanium Alloy vs Inconel Infographic

materialdif.com

materialdif.com