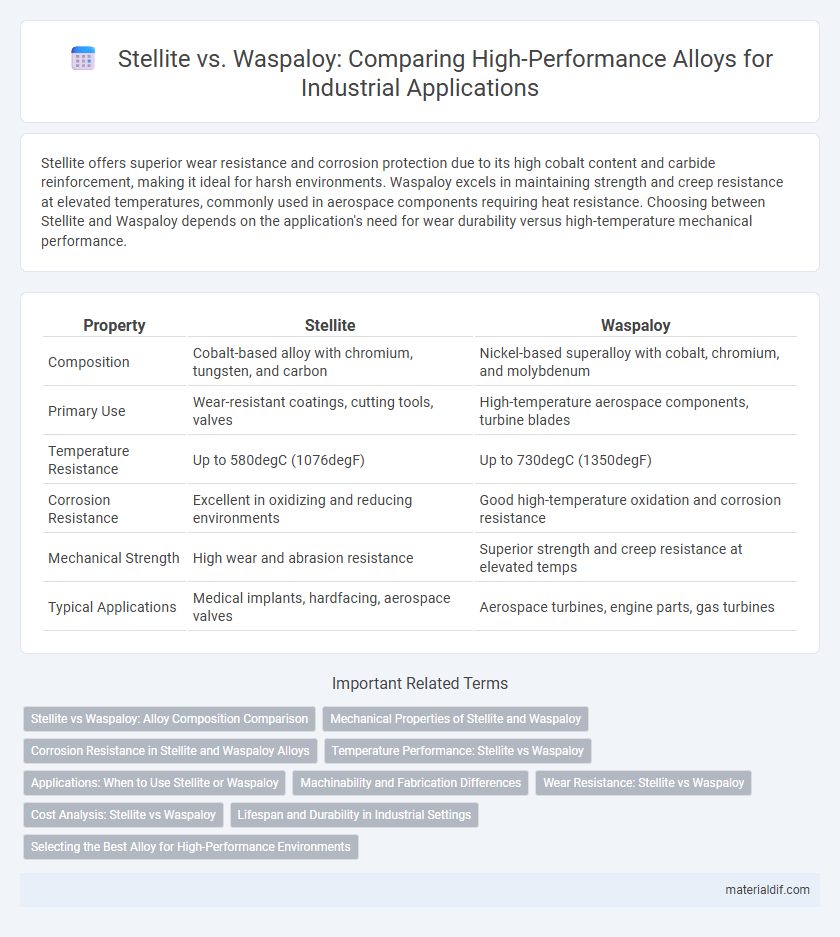

Stellite offers superior wear resistance and corrosion protection due to its high cobalt content and carbide reinforcement, making it ideal for harsh environments. Waspaloy excels in maintaining strength and creep resistance at elevated temperatures, commonly used in aerospace components requiring heat resistance. Choosing between Stellite and Waspaloy depends on the application's need for wear durability versus high-temperature mechanical performance.

Table of Comparison

| Property | Stellite | Waspaloy |

|---|---|---|

| Composition | Cobalt-based alloy with chromium, tungsten, and carbon | Nickel-based superalloy with cobalt, chromium, and molybdenum |

| Primary Use | Wear-resistant coatings, cutting tools, valves | High-temperature aerospace components, turbine blades |

| Temperature Resistance | Up to 580degC (1076degF) | Up to 730degC (1350degF) |

| Corrosion Resistance | Excellent in oxidizing and reducing environments | Good high-temperature oxidation and corrosion resistance |

| Mechanical Strength | High wear and abrasion resistance | Superior strength and creep resistance at elevated temps |

| Typical Applications | Medical implants, hardfacing, aerospace valves | Aerospace turbines, engine parts, gas turbines |

Stellite vs Waspaloy: Alloy Composition Comparison

Stellite is primarily a cobalt-chromium alloy known for exceptional hardness and wear resistance, containing significant amounts of cobalt, chromium, and tungsten. Waspaloy is a nickel-based superalloy with a composition rich in nickel, chromium, cobalt, and molybdenum, optimized for high-temperature strength and corrosion resistance. Comparing alloy composition, Stellite excels in wear resistance due to its cobalt matrix, while Waspaloy provides superior mechanical properties at elevated temperatures because of its nickel-centric microstructure.

Mechanical Properties of Stellite and Waspaloy

Stellite exhibits exceptional wear resistance and hardness due to its high cobalt content and carbide microstructure, making it ideal for high-friction applications. Waspaloy offers superior strength and creep resistance at elevated temperatures, thanks to its nickel-based composition and gamma-prime precipitates. While Stellite excels in abrasion and corrosion resistance, Waspaloy is preferred for mechanical durability in aerospace and turbine engine components.

Corrosion Resistance in Stellite and Waspaloy Alloys

Stellite alloys exhibit superior corrosion resistance due to their high cobalt and chromium content, which forms a stable, protective oxide layer in aggressive environments. Waspaloy, primarily a nickel-based superalloy, offers good corrosion resistance but is more susceptible to oxidation and stress corrosion cracking compared to Stellite. In applications requiring exceptional wear and corrosion resistance, Stellite's composition makes it more effective in harsh chemical and high-temperature conditions.

Temperature Performance: Stellite vs Waspaloy

Stellite alloys exhibit excellent temperature performance with high hardness and wear resistance up to 870degC (1600degF), making them ideal for cutting tools and wear-resistant components at elevated temperatures. Waspaloy maintains exceptional strength and creep resistance up to 700degC (1300degF), commonly used in aerospace turbine engines where thermal stability is critical. Stellite outperforms Waspaloy in extreme wear conditions beyond 700degC, whereas Waspaloy offers superior mechanical properties and oxidation resistance below this threshold.

Applications: When to Use Stellite or Waspaloy

Stellite is ideal for applications requiring extreme wear resistance, corrosion resistance, and high-temperature strength, such as cutting tools, valve seats, and aerospace components exposed to severe conditions. Waspaloy excels in high-temperature environments like gas turbine engines and jet engine components, offering superior strength and oxidation resistance up to 704degC (1300degF). Select Stellite for abrasive or corrosive service conditions and Waspaloy for high-performance applications demanding durability under thermal stress.

Machinability and Fabrication Differences

Stellite exhibits superior wear resistance and hardness, making it more challenging to machine compared to Waspaloy, which offers better machinability due to its balanced composition of nickel, cobalt, and chromium. Fabrication of Stellite requires specialized tooling and slow cutting speeds to manage its toughness and hard carbide phases, whereas Waspaloy allows easier machining and forming processes because of its heat-treatable nature and ductility. The trade-off between Stellite's exceptional surface durability and Waspaloy's efficient fabrication drives material selection in high-performance engineering applications.

Wear Resistance: Stellite vs Waspaloy

Stellite exhibits superior wear resistance due to its high cobalt content and carbide precipitates, making it ideal for applications involving abrasive environments. Waspaloy, an iron-nickel-based superalloy, offers good wear resistance but primarily excels in high-temperature strength rather than abrasion resistance. Comparing microstructures, Stellite's hard carbides provide enhanced surface durability compared to Waspaloy's predominantly solid-solution strengthening mechanisms.

Cost Analysis: Stellite vs Waspaloy

Stellite alloys generally exhibit higher material costs compared to Waspaloy due to their cobalt-based composition and superior wear resistance properties. Waspaloy, a nickel-based superalloy, offers cost advantages in production and machining while maintaining excellent high-temperature strength and corrosion resistance. Choosing between Stellite and Waspaloy depends on balancing upfront material expenses with lifecycle performance requirements in demanding applications.

Lifespan and Durability in Industrial Settings

Stellite alloys demonstrate exceptional lifespan and durability in industrial settings due to their high resistance to wear, corrosion, and elevated temperatures, making them ideal for cutting tools and valve components. Waspaloy, a nickel-based superalloy, exhibits excellent mechanical strength and oxidation resistance at high temperatures, ensuring prolonged structural integrity in gas turbines and aerospace applications. The choice between Stellite and Waspaloy depends on specific environmental stresses, with Stellite favored for abrasive conditions and Waspaloy preferred for high-temperature endurance.

Selecting the Best Alloy for High-Performance Environments

Stellite alloys excel in high-performance environments requiring exceptional wear resistance, corrosion protection, and heat stability, making them ideal for cutting tools and valve components. Waspaloy demonstrates superior mechanical strength and oxidation resistance at elevated temperatures, often exceeding 700degC, which is crucial for aerospace turbine blades and jet engine parts. Selecting between Stellite and Waspaloy depends on the specific operational stresses, temperature range, and wear conditions of the application for optimal performance and longevity.

Stellite vs Waspaloy Infographic

materialdif.com

materialdif.com