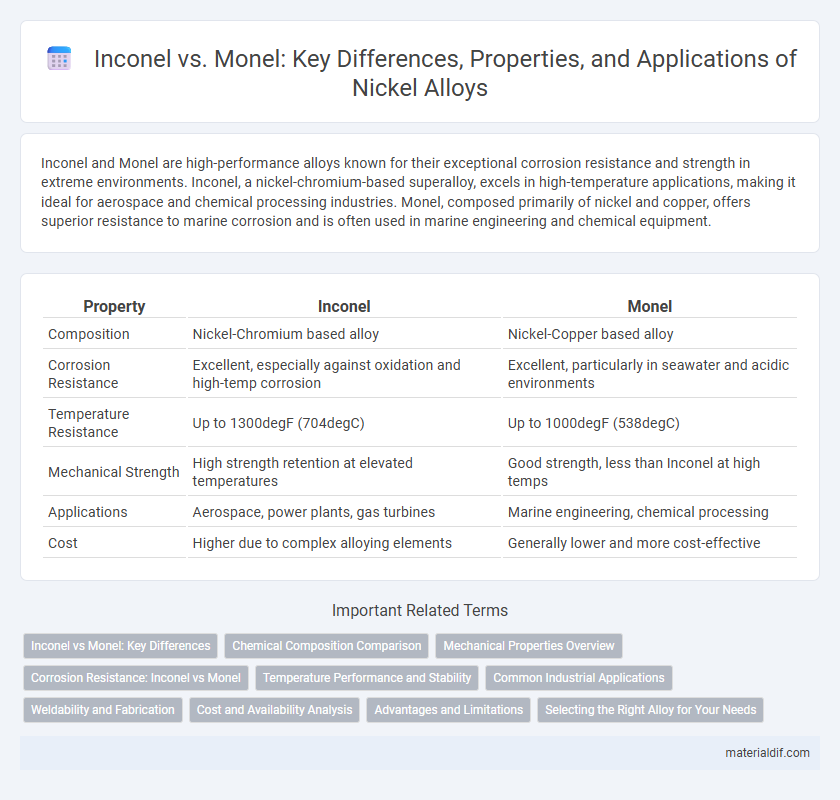

Inconel and Monel are high-performance alloys known for their exceptional corrosion resistance and strength in extreme environments. Inconel, a nickel-chromium-based superalloy, excels in high-temperature applications, making it ideal for aerospace and chemical processing industries. Monel, composed primarily of nickel and copper, offers superior resistance to marine corrosion and is often used in marine engineering and chemical equipment.

Table of Comparison

| Property | Inconel | Monel |

|---|---|---|

| Composition | Nickel-Chromium based alloy | Nickel-Copper based alloy |

| Corrosion Resistance | Excellent, especially against oxidation and high-temp corrosion | Excellent, particularly in seawater and acidic environments |

| Temperature Resistance | Up to 1300degF (704degC) | Up to 1000degF (538degC) |

| Mechanical Strength | High strength retention at elevated temperatures | Good strength, less than Inconel at high temps |

| Applications | Aerospace, power plants, gas turbines | Marine engineering, chemical processing |

| Cost | Higher due to complex alloying elements | Generally lower and more cost-effective |

Inconel vs Monel: Key Differences

Inconel is a nickel-chromium-based superalloy known for exceptional oxidation and corrosion resistance at high temperatures, making it ideal for aerospace and chemical processing. Monel, composed mainly of nickel and copper, excels in resistance to seawater corrosion and acids, suited for marine and chemical environments. Key differences include Inconel's superior high-temperature strength and oxidation resistance versus Monel's enhanced resistance to chloride ion stress corrosion cracking and its excellent weldability.

Chemical Composition Comparison

Inconel primarily consists of nickel (50-70%), chromium (14-21%), and iron, with smaller amounts of molybdenum, cobalt, and manganese, providing excellent corrosion and oxidation resistance. Monel is predominantly nickel (up to 67%) combined with copper (20-29%), along with iron, manganese, and trace amounts of other elements, offering high strength and good corrosion resistance in marine environments. The key chemical difference is Monel's significant copper content versus Inconel's chromium and molybdenum, impacting their respective corrosion resistance and mechanical properties.

Mechanical Properties Overview

Inconel alloys offer exceptional tensile strength and superior high-temperature resistance, making them ideal for extreme environments such as jet engines and chemical processing. Monel alloys provide excellent corrosion resistance and good mechanical strength, particularly in marine and acidic conditions, while maintaining moderate ductility and toughness. Both alloys exhibit distinct mechanical properties suited for specialized applications where strength, durability, and environmental resistance are critical factors.

Corrosion Resistance: Inconel vs Monel

Inconel exhibits superior corrosion resistance compared to Monel, particularly in extreme environments involving high temperatures and oxidizing conditions. Its high nickel and chromium content enables Inconel alloys to resist oxidation, pitting, and crevice corrosion more effectively than Monel, which performs better in marine and reducing environments due to its high copper content. Consequently, Inconel is preferred for aerospace and chemical processing applications where aggressive oxidation and high-temperature stability are critical.

Temperature Performance and Stability

Inconel alloys exhibit superior temperature performance and stability, maintaining strength and corrosion resistance at extreme temperatures up to 2200degF (1204degC). Monel alloys, while excellent in corrosion resistance, generally perform best under moderate temperature conditions, typically up to 1100degF (593degC), where their mechanical properties remain stable. For high-temperature applications requiring oxidation resistance and dimensional stability, Inconel is the preferred choice over Monel.

Common Industrial Applications

Inconel is widely used in aerospace, power generation, and chemical processing due to its excellent high-temperature strength and corrosion resistance. Monel is favored in marine engineering, chemical reactors, and hydrocarbon extraction for its superior resistance to seawater corrosion and acidic environments. Both alloys serve critical roles in industries requiring durability under extreme conditions, with Inconel excelling in oxidation resistance and Monel providing outstanding performance in reducing environments.

Weldability and Fabrication

Inconel offers superior weldability due to its excellent resistance to oxidation and high-temperature strength, making it ideal for aerospace and chemical processing applications requiring robust joints. Monel exhibits good weldability and is highly malleable, allowing for easier fabrication in marine and chemical environments where corrosion resistance and ductility are essential. Both alloys require specialized welding techniques, but Monel's lower melting point facilitates simpler fabrication compared to Inconel's complex heat treatments.

Cost and Availability Analysis

Inconel alloys typically have a higher cost due to their nickel-chromium composition and superior performance in extreme environments, making them less widely available than Monel. Monel, composed primarily of nickel and copper, offers a more cost-effective solution with better availability for applications requiring corrosion resistance and moderate strength. Supply chain dynamics and raw material demand also influence price fluctuations and lead times for both alloys.

Advantages and Limitations

Inconel offers superior high-temperature strength and excellent resistance to oxidation and corrosion, making it ideal for aerospace and chemical processing applications. Monel provides outstanding resistance to seawater corrosion and excellent mechanical properties at moderate temperatures, favored in marine and hydrocarbon environments. However, Inconel is generally more expensive and challenging to machine, while Monel can be less effective in high-temperature conditions and is prone to stress corrosion cracking under certain environments.

Selecting the Right Alloy for Your Needs

Inconel alloys offer exceptional resistance to high temperatures and corrosion, making them ideal for aerospace and chemical processing applications, while Monel alloys excel in marine environments due to their outstanding resistance to seawater and acidic solutions. Selecting the right alloy depends on factors such as operating temperature, exposure to corrosive elements, and mechanical strength requirements. For high-temperature, oxidative environments, Inconel provides superior performance, whereas Monel is more suitable for applications involving saltwater or acidic conditions.

Inconel vs Monel Infographic

materialdif.com

materialdif.com